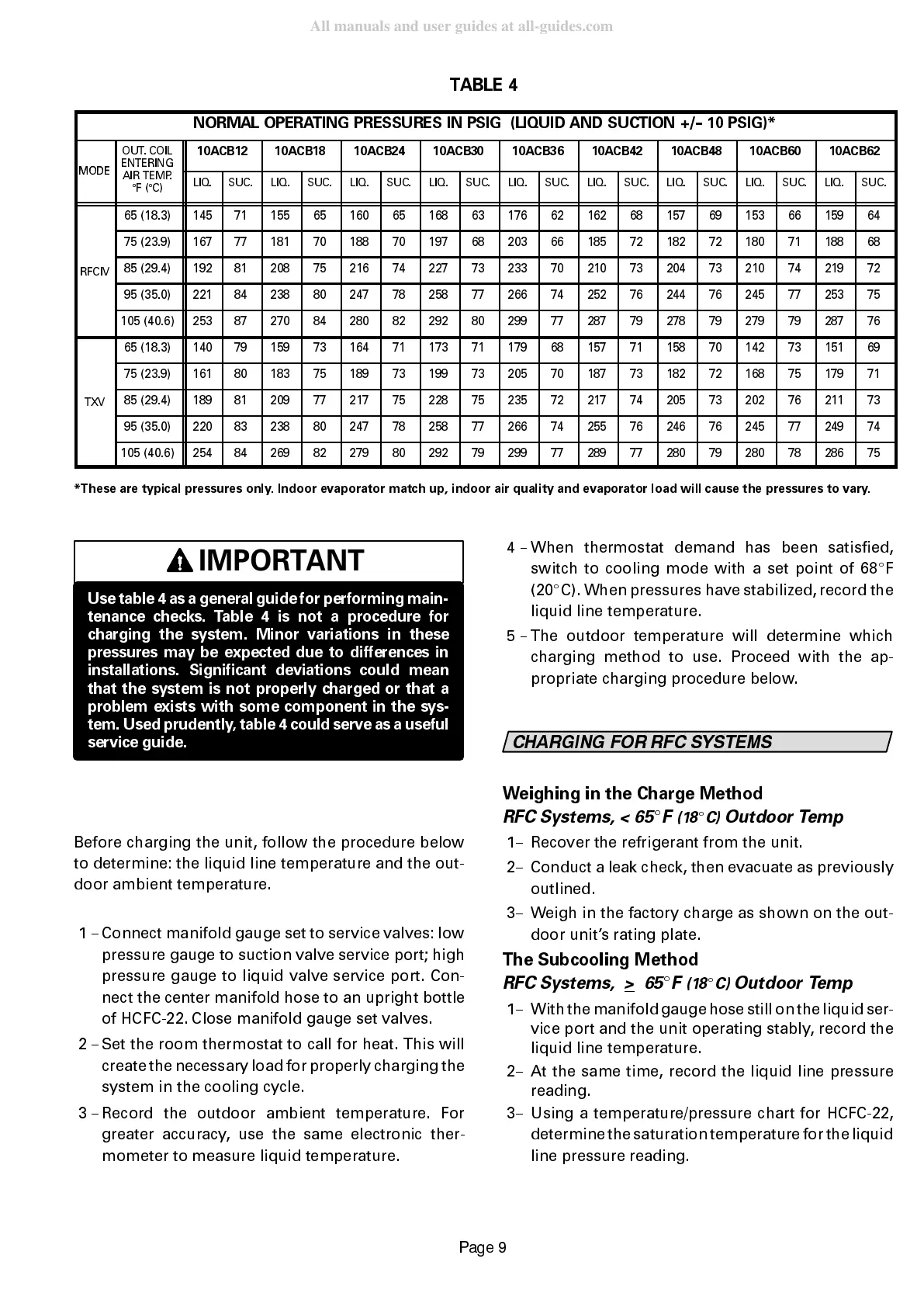

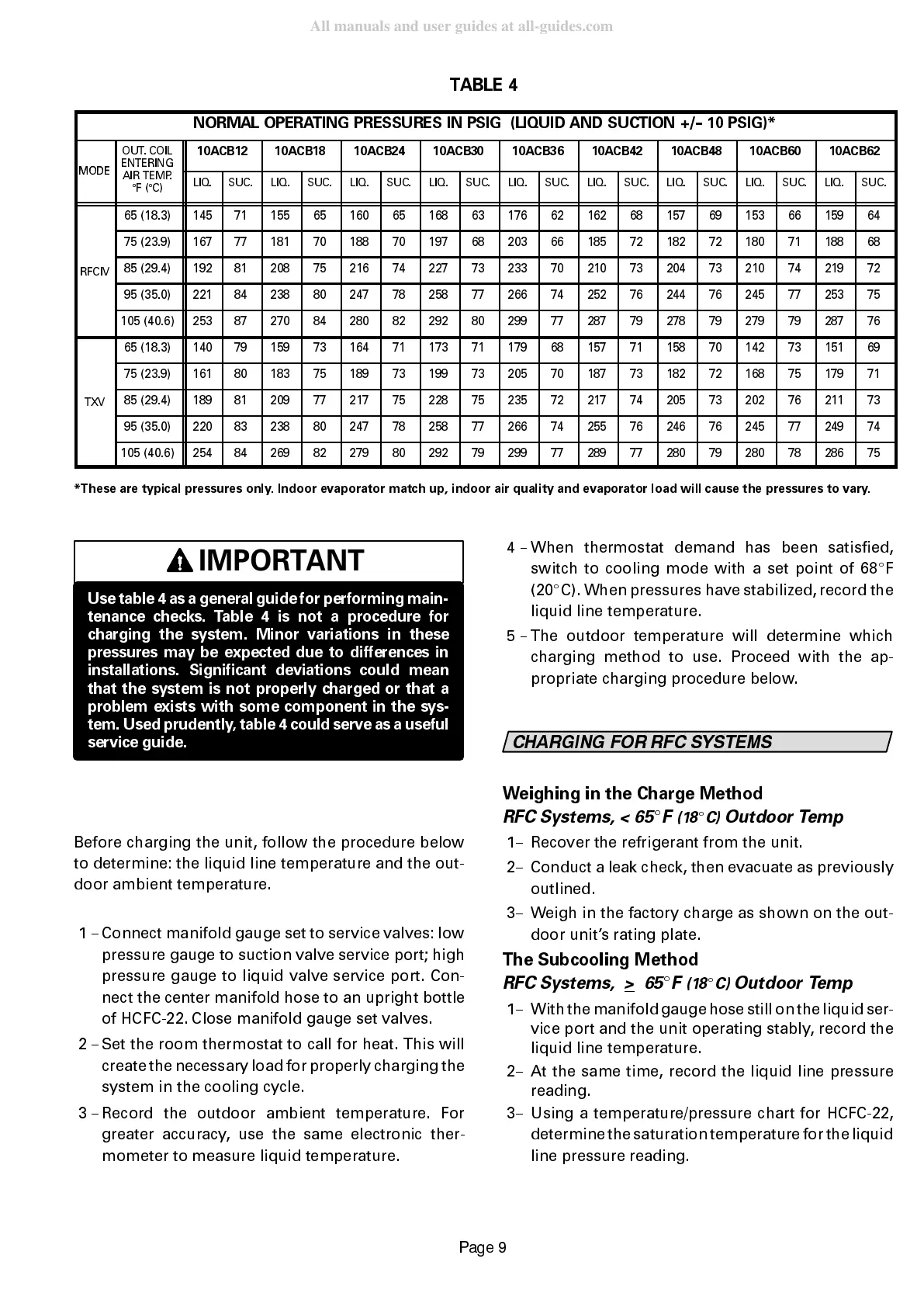

AIR TEMP.

q

F(

q

C)

LIQ. SUC. LIQ. SUC. LIQ. SUC. LIQ. SUC. LIQ. SUC. LIQ. SUC. LIQ. SUC. LIQ. SUC. LIQ. SUC.

65 (18.3) 145

71 155 65 160 65 168 63 176 62 162 68 157 69 153 66 159 64

75 (23.9) 167 77 181 70 188 70 197 68 203 66 185 72 182 72 180 71 188 68

RFCIV

85 (29.4) 192 81 208 75 216 74 227 73 233 70 210 73 204 73 210 74 219 72

95 (35.0) 221 84 238 80 247 78 258 77 266 74 252 76 244 76 245 77 253 75

105 (40.6) 253 87 270 84 280 82 292 80 299 77 287 79 278 79 279 79 287 76

65 (18.3) 140 79 159 73 164 71 173 71 179 68 157 71 158 70 142 73 151 69

75 (23.9) 161 80 183 75 189 73 199 73 205 70 187 73 182 72 168 75 179 71

TXV

85 (29.4) 189 81 209 77 217 75 228 75 235 72 217 74 205 73 202 76 211 73

95 (35.0) 220 83 238 80 247 78 258 77 266 74 255 76 246 76 245 77 249 74

105 (40.6) 254 84 269 82 279 80 292 79 299 77 289 77 280 79 280 78 286 75

*These are typical pressures only. Indoor evaporator match up, indoor air quality and evaporator load will cause the pressures to vary.

IMPORTANT

Use table 4 as a general guide for performing main-

tenance checks. Table 4 is not a procedure for

charging the system. Minor variations in these

pressures may be expected due to differences in

installations. Significant deviations could mean

that the system is not properly charged or that a

problem exists with some component in the sys-

tem. Used prudently, table 4 could serve as a useful

service guide.

Before charging the unit, follow the procedure below

to determine: the liquid line temperature and the out-

door ambient temperature.

1 -- Connect manifold gauge set to service valves: low

pressure gauge to suction valve service port; high

pressure gauge to liquid valve service port. Con-

nect the center manifold hose to an upright bottle

of HCFC-22. Close manifold gauge set valves.

2 -- Set the room thermostat to call for heat. This will

create the necessary load for properly charging the

system in the cooling cycle.

3 -- Record the outdoor ambient temperature. For

greater accuracy, use the same electronic ther-

mometer to measure liquid temperature.

4 -- When thermostat demand has been satisfied,

switch to cooling mode with a set point of 68

E

F

(20

E

C). When pressures have stabilized, record the

liquid line temperature.

5 -- The outdoor temperature will determine which

charging method to use. Proceed with the ap-

propriate charging procedure below.

&+$5*,1* )25 5)& 6<67(06

Weighing in the Charge Method

RFC Systems, < 65

E

F

(18

E

C)

Outdoor Temp

1-- Recover the refrigerant from the unit.

2-- Conduct a leak check, then evacuate as previously

outlined.

3-- Weigh in the factory charge as shown on the out-

door units rating plate.

The Subcooling Method

RFC Systems, >

65

E

F

(18

E

C)

Outdoor Temp

1-- With themanifold gauge hose still on theliquid ser-

vice port and the unit operating stably, record the

liquid line temperature.

2-- At the same time, record the liquid line pressure

reading.

3-- Using a temperature/pressure chart for HCFC-22,

determinethe saturation temperature for the liquid

line pressure reading.

Loading...

Loading...