2. SETTING

THE

MAXIMUM

LIFT

ARMS

TRAVEL

The

condition

of

upper

lift

arms

stopping

at max·

imum

height should

occur

automatically

follow·

ing the rotation

of

the spool

to

neutral setting,

which allows the

inlet

oil

to

drain

out

freely.

If not, the piston would end

its

stroke when the

inside

rockshaft

control

lever is stopped by

the

hydraulic

lift

body and, under these

conditions,

the

oil

under pressure delivered by

the

pump

would drain

out

through

the

pressure relief valve.

Adjust

as follows:

1.

Apply a load

of

at least 110 lb.

(50

kg.)

to

the

three-point

lower

links.

2.

Start the engine. and run

it

up

to

medium

speed.

3.

Raise the arms and set the hydraulic

lift

con-

trol lever (Item

A,

Fig. C.0/20) at the highest

point in the control quadrant.

4.

In

this

position, scribe

two

assembly marks

(Items

s,

and

S2,

Diagram

C),

in register, on

the hydraulic

lift

body and on the cam in-

tegral with the right side arm.

5.

Slowly unscrew a few turns

the

arms max-

imum

lift

stop

screw (Item

10)

until

the

pressure relief valve (Item

1,

Fig. C.0/1)

opens.

6.

Make sure that the residual upward travel by

the

lift

arms

following

the opening

of

the

pressure relief valve is comprised between

0.158-0.197 in.

(4-5

mm.) in (Item d., Fig.

C.0/20) as measured at the quoted assembly

marks. If the residual travel

is

less, then

reduce the

shims

(Item

N)

under the head

of

the screw (Item 10), and

if

more, then add

shims.

In the course

of

adjustment,

hold

the

hydraulic

lift

control

lever at

the

lower

stop.

A CAUTION: No variation

of

the

lift

arms travel

length

following

a reduction

or

an Increase

of

the

number

of

shims

inserted under

the

head

of

the

screw

is probably caused by wrong assemblage

or

inside leverage deformation: In

this

case In-

spect and

check

the

hydraulic

lift

inside

com·

ponents.

3.

SENSITIVITY ADJUSTMENT

To be

functionally

efficient,

the

pulling

action

re-

quires

the

maximum

sensitivity

of

the reaction

by the control valve spool (Item 6, Fig. C.0/21).

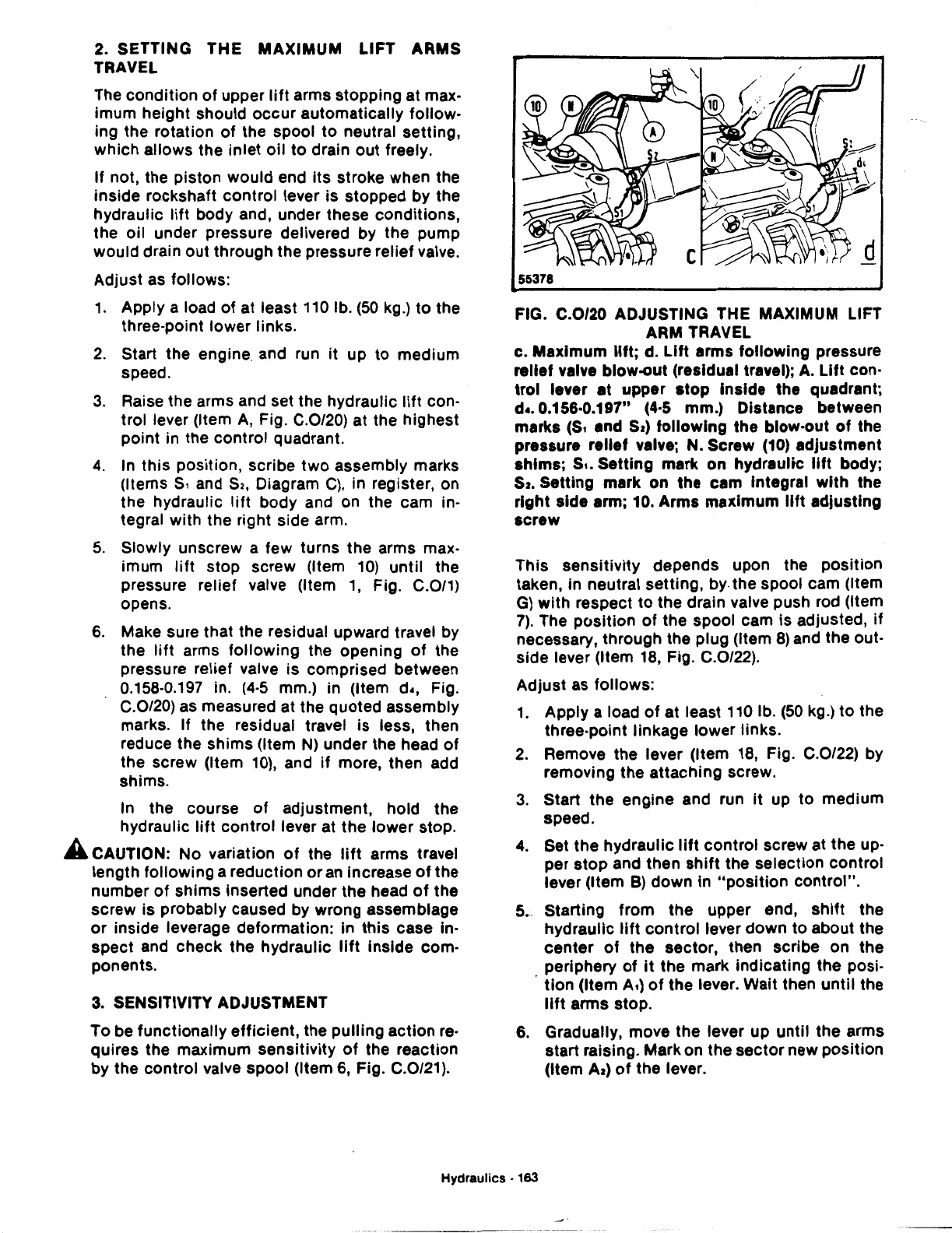

55378

FIG. C.0/20 ADJUSTING THE MAXIMUM LIFT

ARM TRAVEL

c.

Maximum

lift;

d.

Lift

arms

following

pressure

relief valve blow-out (residual travel);

A.

Lift

con-

trol

lever

at

upper

stop

Inside the quadrant;

d •. 0.156·0.197" (4·5 mm.) Distance between

marks

(St

and

Sz)

following

the blow-out

of

the

pressure

relief

valve; N. Screw (10) adjustment

shims;

St.

Setting

mark

on

hydraultc

lift

body;

Sz.

Setting

mark

on

the

cam

Integral

with

the

right

side arm; 10.

Arms

maximum

lift

adjusting

screw

This

sensitivity

depends upon the

position

taken, in neutral setting,

by.

the spool cam (Item

G)

with

respect

to

the

drain valve push rod (Item

7).

The

position

of

the spool cam is adjusted,

if

necessary, through the plug (Item

8)

and the out-

side lever (Item

18,

Fig. C.0/22).

Adjust

as

follows:

1.

Apply a load

of

at least 110 lb.

(50

kg.)

to

the

three-point linkage lower links.

2.

Remove

the

lever (Item 18, Fig. C.0/22) by

removing

the

attaching

screw.

3.

Start

the

engine and run

it

up to medium

speed.

4.

Set

the

hydraulic

lift

control

screw at

the

up-

per

stop

and then

shift

the selection

control

lever (Item

B)

down

In

"position

control".

5. Starting

from

the

upper end,

shift

the

hydraulic

lift

control

lever

down

to

about the

center

of

the

sector, then scribe on

the

periphery

of

It

the

mark

indicating

the posi-

.

tlon

(Item At)

of

the lever. Wait then

until

the

lift

arms stop.

6. Gradually, move

the

lever up

until

the

arms

start raising. Mark on

the

sector

new position

(Item

Az)

of

the

lever.

Hydraulics - 163

Loading...

Loading...