Repair

P 2 / 5

< 1 > Lubrication

Apply 15 g of MAKITA grease K No.1 in gear housing

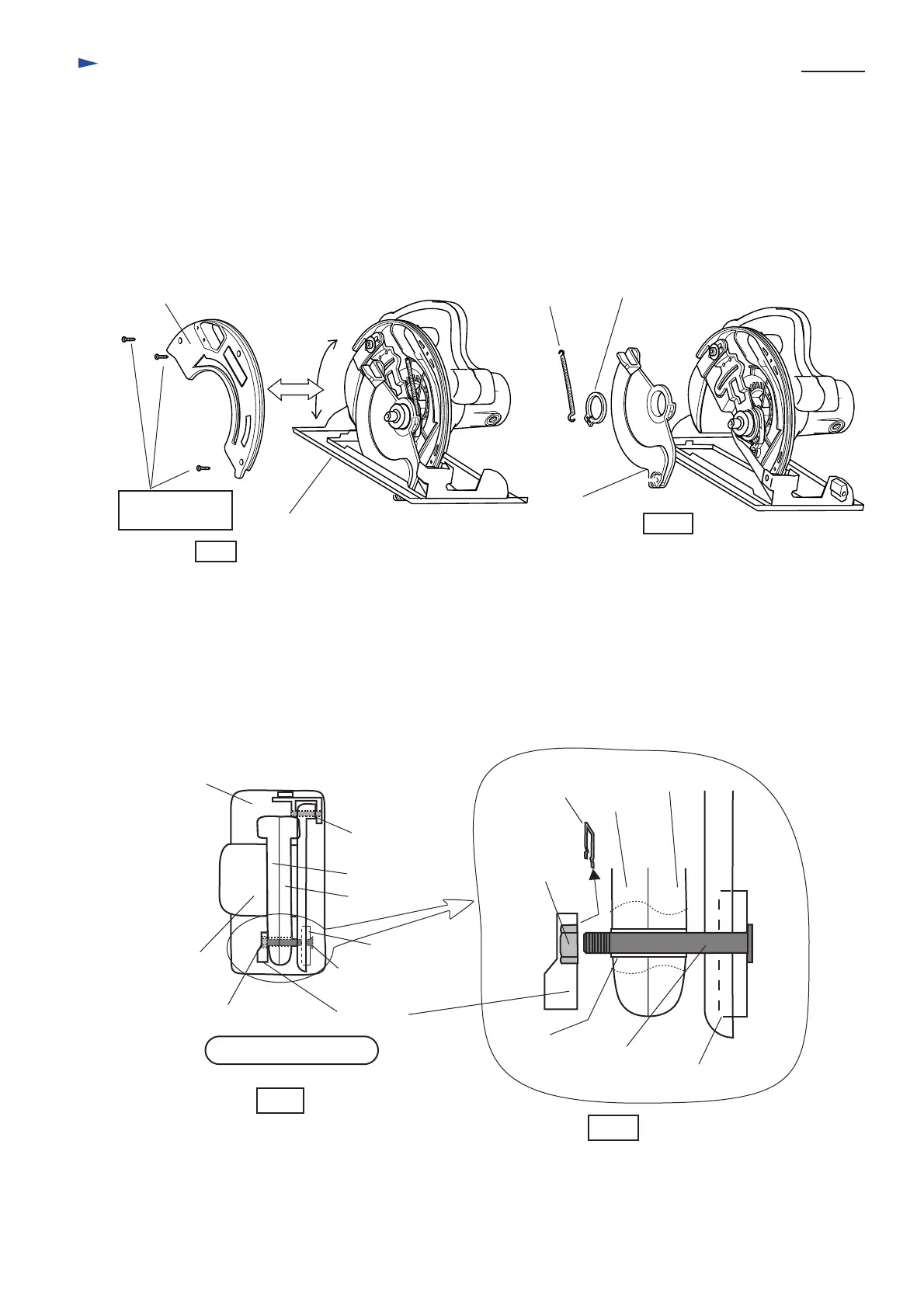

< 2 > Separating base from the motor section

( 1 ) After pulling base down to the minimum cutting depth, disassemble blade case cover by taking off 3 pcs. of

tapping screws CT 4x20 as illustrated in Fig.1 for easy disassembling in the next process.

First of all, detach the saw blade for safety repair.

Blade case cover

Fig.1

( 2 ) Disassemble tension spring 4, retaining ring S-40 and safety cover as illustrated in Fig. 1A.

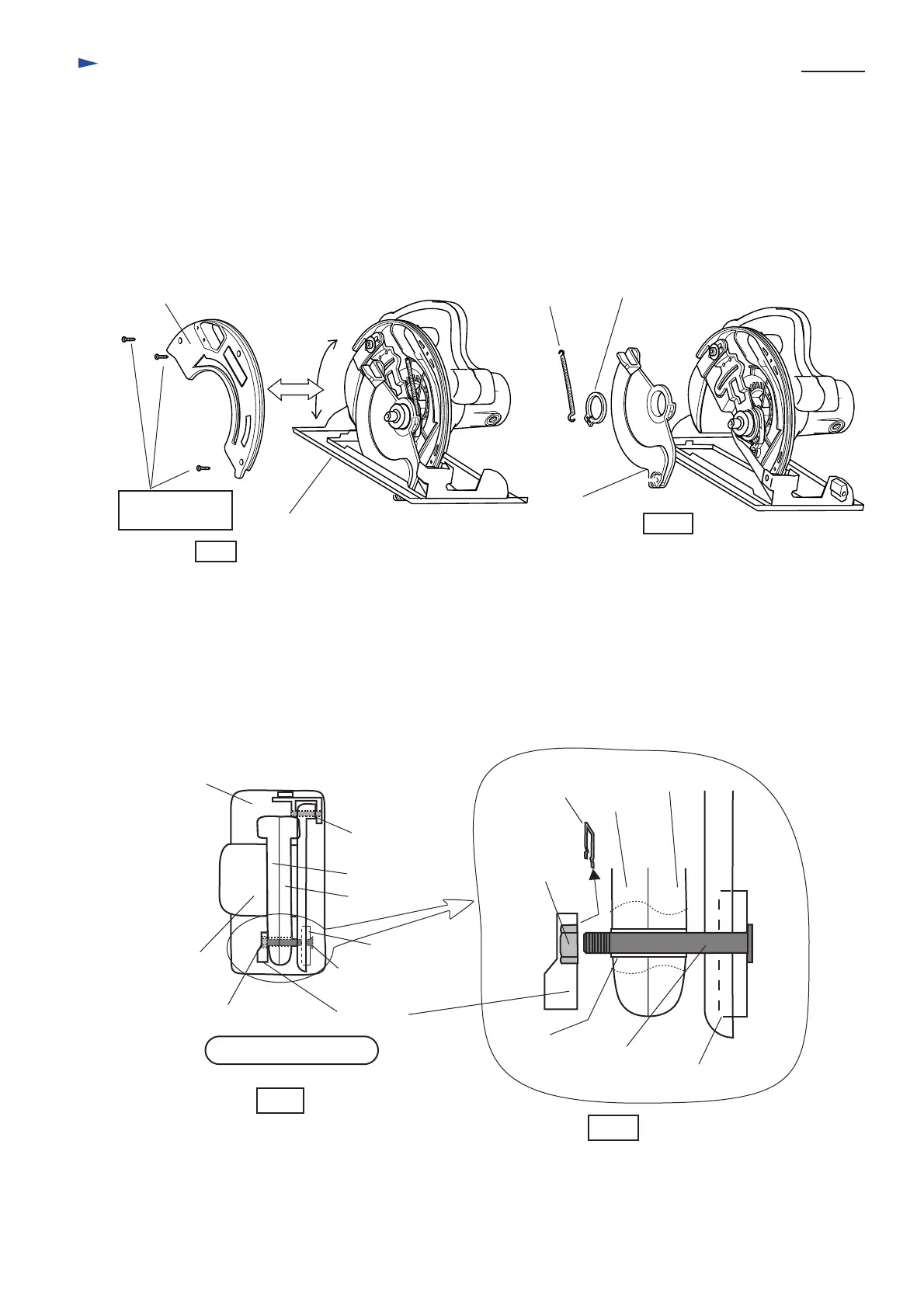

( 3 ) Base and the motor section is fixed with pin 10 and cap square neck bolt M8x98 as illustrated in Fig. 2.

Take off ring spring 12 from lever 54, and disassemble lever 54 together with hex nut M8

from cap square neck bolt M8x98 as illustrated in Fig.2A. Then, cap square neck bolt M8x98 can be

separated from the base section. Thus, the motor section has been made free from depth guide.

Tapping screws

CT 4x20

Pull base down to the minimum

cutting depth.

Tension

spring 4

Retaining ring S-40

Safety cover

Fig.1A

Base

Motor

section

Lever 54

Cap square

neck bolt M8x98

Hex nut M8

Pin 10

Fig. 2

Handle L

Handle R

Depth guide

Depth guide

Ring spring 12

Cap square

neck bolt M8x98

Hex nut M8

Handle L

Handle R

Top view of Mod.5705R

Pipe 9

Fig.2A

< Note > Take same step, when disassembling and assembling switch section.

Loading...

Loading...