3 - 123 - 12

to cool.to cool.

- Open the I.C. engine cover.- Open the I.C. engine cover.

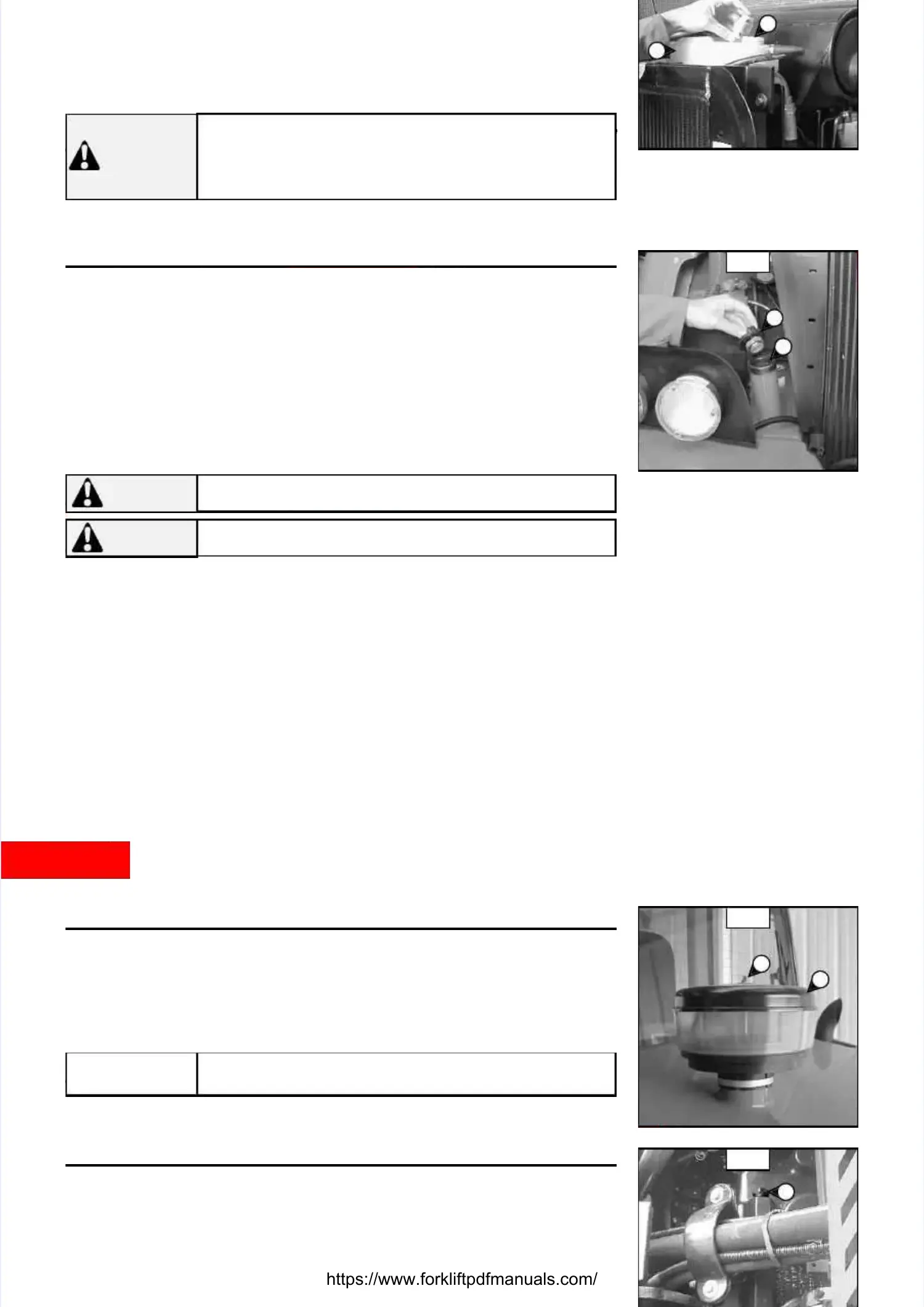

- The liquid must be - The liquid must be situated half way up the expansion pan 1 (fig. A2).situated half way up the expansion pan 1 (fig. A2).

- If necess- If necessary,ary, add cooling liquid (see add cooling liquid (see : 3 - MAINTENANCE: 3 - MAINTENANCE : LUBRICANTS : LUBRICANTS AND FUEL) by AND FUEL) by thethe

filler port 2 (fig. A2).filler port 2 (fig. A2).

To avoid any risk of spraying or burning, wait until the I.C. engine has cooled down before

To avoid any risk of spraying or burning, wait until the I.C. engine has cooled down before

removing the cooling circuit filler plug. If the cooling liquid is very hot, add only hot cooling liq-removing the cooling circuit filler plug. If the cooling liquid is very hot, add only hot cooling liq-

uid (80°C). In an emergency, you can use water as a cooling liquid, then change the uid (80°C). In an emergency, you can use water as a cooling liquid, then change the cooling cir-cooling cir-

cuit liquid as soon as possible (see : 3 - MAINTENANCE : F1 - COOLING LIQUID).cuit liquid as soon as possible (see : 3 - MAINTENANCE : F1 - COOLING LIQUID).

A3 - FA3 - FUEUELL LELEVEVELL

CHECKCHECK

Keep the fueKeep the fuel tank near full,l tank near full, to reduce as much as to reduce as much as possible any condenspossible any condensation due toation due to

atmospheric conditions.atmospheric conditions.

- Open the I.C. engine cover.- Open the I.C. engine cover.

- Remove cap 1 (fig. A3).- Remove cap 1 (fig. A3).

- Fill the f- Fill the fuel tanuel tank with cleak with clean fuel (sn fuel (see : 3 - MAINee : 3 - MAINTENANCTENANCEE : LUBR: LUBRICANTS ICANTS AND FUELAND FUEL ),), fil-fil-

tered through tered through a strainer a strainer or a cleanor a clean,, lint free lint free cloth,cloth, through filler pthrough filler port 2 (fig. A3).ort 2 (fig. A3).

- Put the cap back 1 (fig. A3).- Put the cap back 1 (fig. A3).

- Check visually that there is no leakage in the tank and pipes.- Check visually that there is no leakage in the tank and pipes.

Never smoke or approach with a flame during filling operations or when the tank is open. Never

Never smoke or approach with a flame during filling operations or when the tank is open. Never

refill while I.C. engine is running.refill while I.C. engine is running.

The fuel tank is degassed via the filler plug. When changing it, with degassing hole.The fuel tank is degassed via the filler plug. When changing it, with degassing hole.

22

A3A3

11

22

11

To avoid risk of spraying or burning, wait until the I.C. engine has cooledTo avoid risk of spraying or burning, wait until the I.C. engine has cooled

down before removing the radiator cap. If the cooling liquid is very hodown before removing the radiator cap. If the cooling liquid is very hot, addt, add

only hot cooling liquid. In an emergency, you can only hot cooling liquid. In an emergency, you can use water as a cooling liq-use water as a cooling liq-

uid, then change the cooling circuid, then change the cooling circuit liquid as soon as possible (seeuit liquid as soon as possible (see : 3 -: 3 -

MAINTENANCEMAINTENANCE : F1 - : F1 - COOLING LIQUIDCOOLING LIQUID).).

WARNINGWARNING

Never smoke or approach with a flame dNever smoke or approach with a flame during filling operations or when theuring filling operations or when the

tank is open. Never refill while the I.C. engine is running.tank is open. Never refill while the I.C. engine is running.

WARNINGWARNING

The fuel tank is vented The fuel tank is vented via the filler plug. When changing it, always use via the filler plug. When changing it, always use anan

original part, with vented hole.original part, with vented hole.

WARNINGWARNING

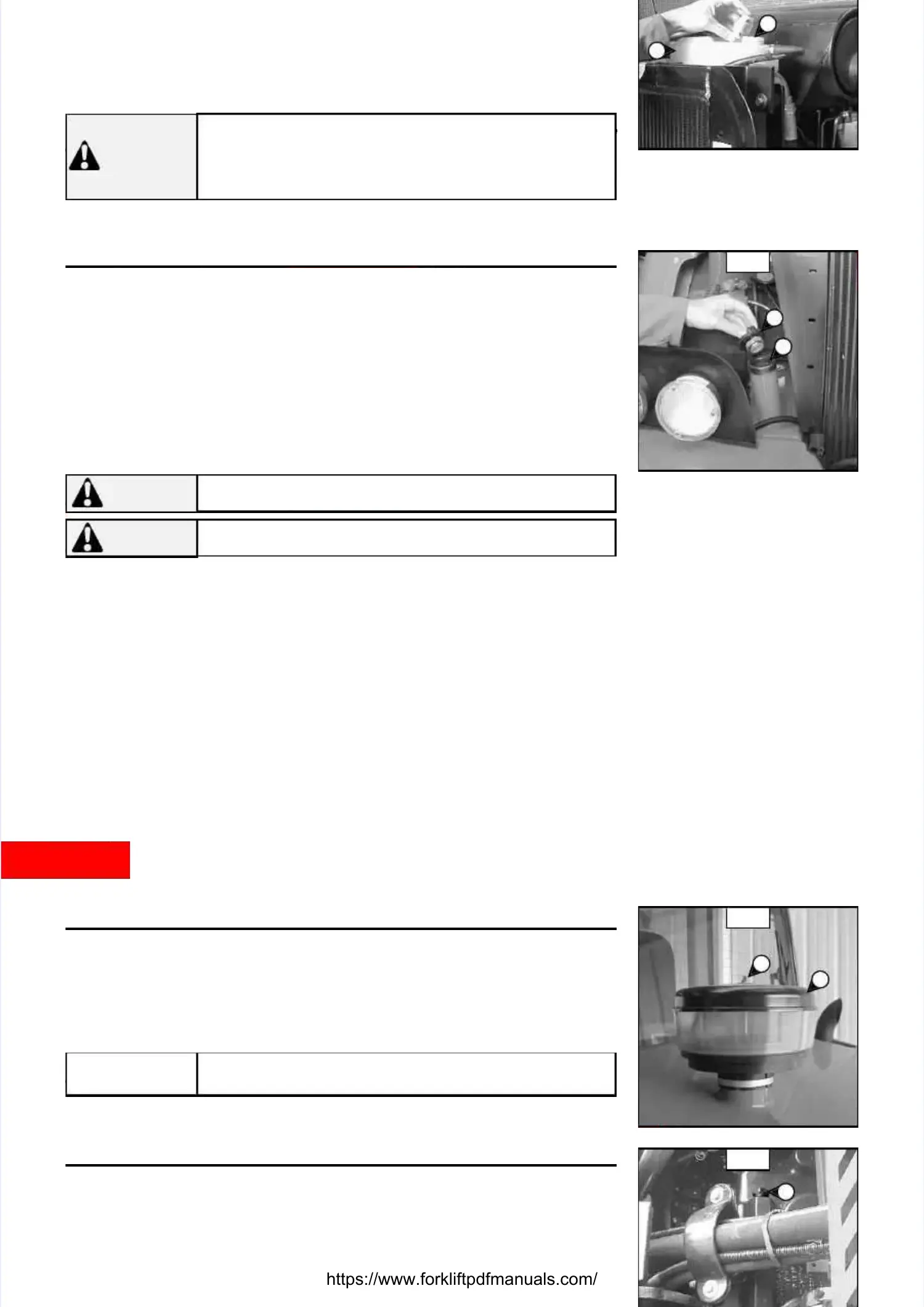

A4 - CA4 - CYCLOYCLONICNIC PRPREFEFILILTETERR

CLEANCLEAN

The cleaning interval is given as a guide,The cleaning interval is given as a guide, however the prefhowever the prefilter must be emptied as soonilter must be emptied as soon

as impurities reach the MAXI level on the tank.as impurities reach the MAXI level on the tank.

- Loosen nut 1 (f- Loosen nut 1 (fig. A4),ig. A4), remove cover 2 (remove cover 2 (fig. A4) and empty the tank.fig. A4) and empty the tank.

- Clean the prefilter unit with a clean dry cloth and reassemble the unit.- Clean the prefilter unit with a clean dry cloth and reassemble the unit.

When cleaning, take care not to let impurities into the dry air filter.

When cleaning, take care not to let impurities into the dry air filter.

A5 - TA5 - TRARANSNSMIMISSSSIOIONN OIOILL LELEVEVELL

CHECKCHECK

Park the lift truck on level ground with the engine cold and at idle.Park the lift truck on level ground with the engine cold and at idle.

- For the minimum oil level,- For the minimum oil level, remove the screw 1 (fig. A5/1) anremove the screw 1 (fig. A5/1) and check that the oil flushesd check that the oil flushes

the port.the port.

- If neces- If necessarysary,, add oiladd oil

- Remove the co- Remove the cover plate 2 (fig. A5/2) and aver plate 2 (fig. A5/2) and add oil (see : 3 - MAINTENANCEdd oil (see : 3 - MAINTENANCE : LUBRICANTS: LUBRICANTS

AND FUEL) b th fill t 3 (fig A5/1)AND FUEL) b th fill t 3 (fig A5/1)

A4A4

A5/1A5/1

11

22

33

When cleaning, take care not to let impurities into the dry air filter.When cleaning, take care not to let impurities into the dry air filter.

IMPORTANTIMPORTANT

CONTENTSCONTENTS

Loading...

Loading...