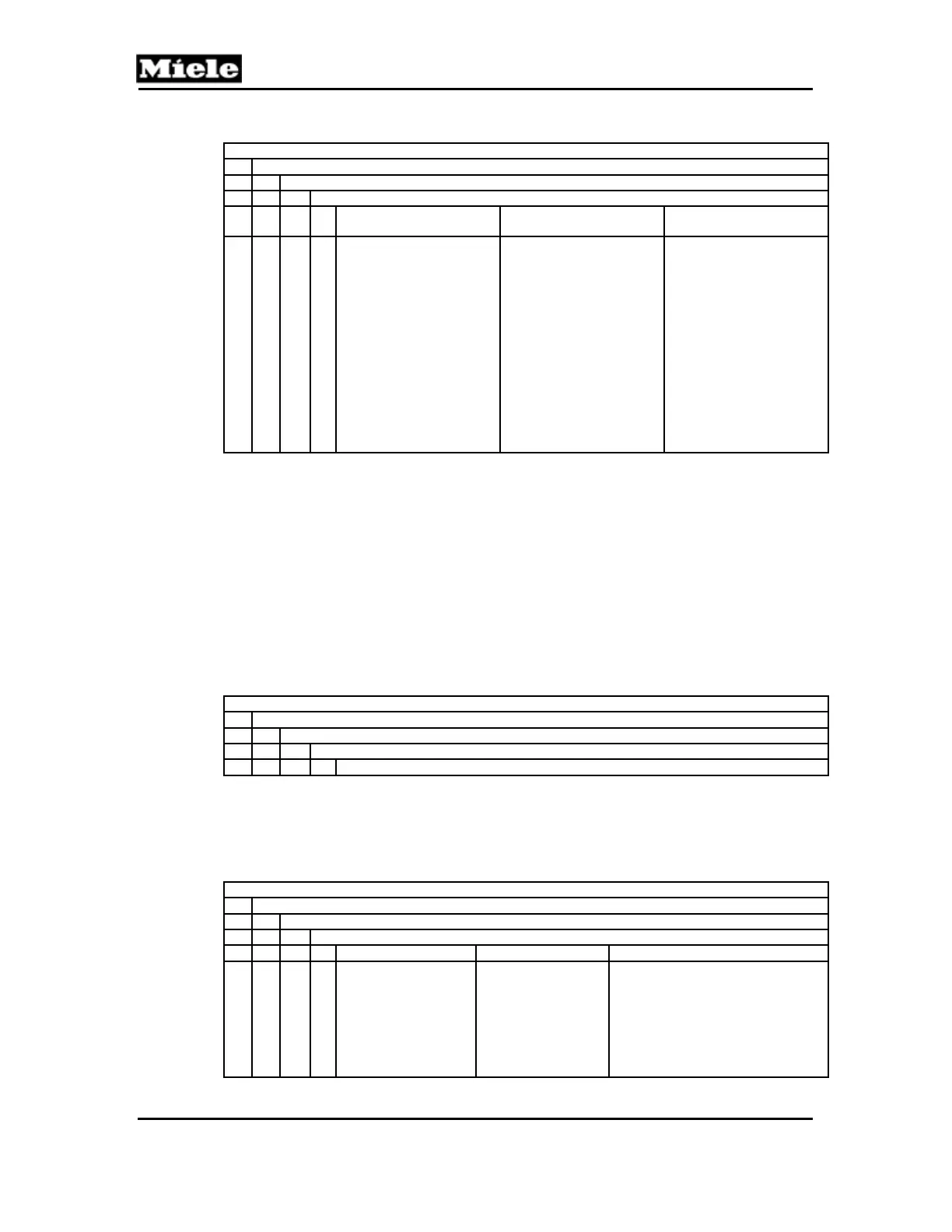

Technical Information

114

PW 6xx7

Service mode (service level)

3 Service settings

1 Basic settings

9 Accident prevention legislation display

1

Accident prevention

legislation display data

Display Explanation

“Accident prevention

legislation display: No”,

Save, Back

Field with value “Yes” or

“No”. The technician can

check this information

later using service mode

or a laptop with MDU. If

“Yes” is programmed, the

message “accident

prevention legislation-test.

Call the service dept.” will

appear in the display after

a year has passed since

the last Reset the accident

prevention legislation

display. Factory setting:

No.

Table 100-87: Accident Prevention Legislation Test

After selecting a value with the multifunction selector switch, confirm it with

the OK button. The control automatically goes back one level.

Save settings by pressing and releasing the Save button.

Pressing the Back button quits without saving and goes back one menu

level.

The drum bearings must be lubricated every 1000 operating hours. A

reminder for the operator can be set, if desired, that will read, “Bearing

maintenance! Call the service department.” After lubrication has been carried

out, the technician can delete the message via service mode.

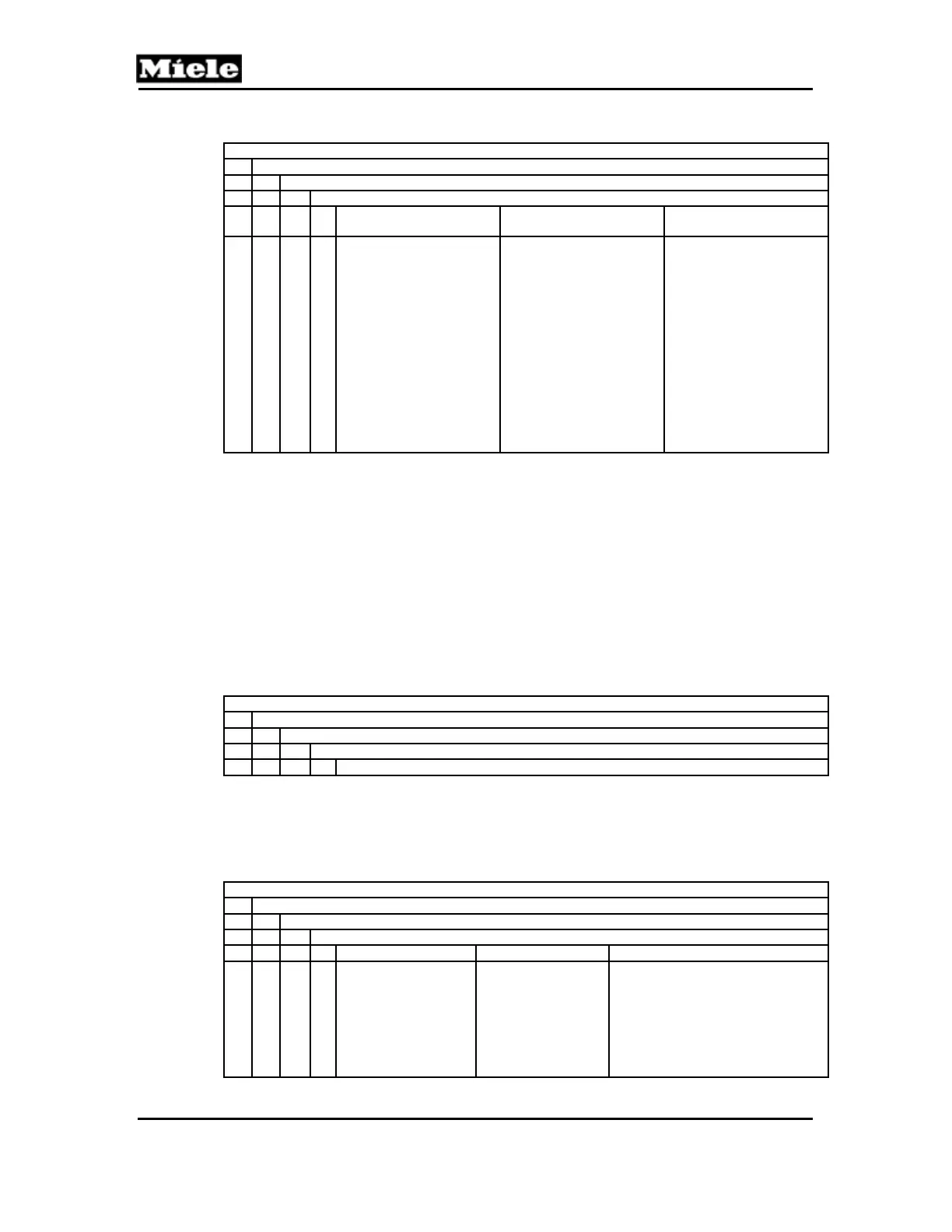

Service mode (service level)

3 Service settings

1 Basic settings

10 Bearing maintenance

1 Bearing maintenance data

Table 100-88: Bearing Maintenance

After selecting a value with the multifunction selector switch, confirm it with

the OK button. The control automatically goes back one level.

Pressing the Back button quits without saving and goes back one menu level.

Service mode (service level)

3 Service settings

1 Basic settings

10 Bearing maintenance

1 Bearing maintenance Display Explanation

“Bearing

maintenance:

Yes, Save, Back”

Field with value “Yes” or “No”. The

technician can check this setting

later using service mode or a laptop

with MDU. If “Yes” is programmed,

the message “Bearing maintenance!

Call the service department” will be

displayed after 1000 operating

hours. Factory setting: No.

Table 100-89: Bearing Maintenance Message Display Programming

Loading...

Loading...