Chapter 8 Adjustment

8–30

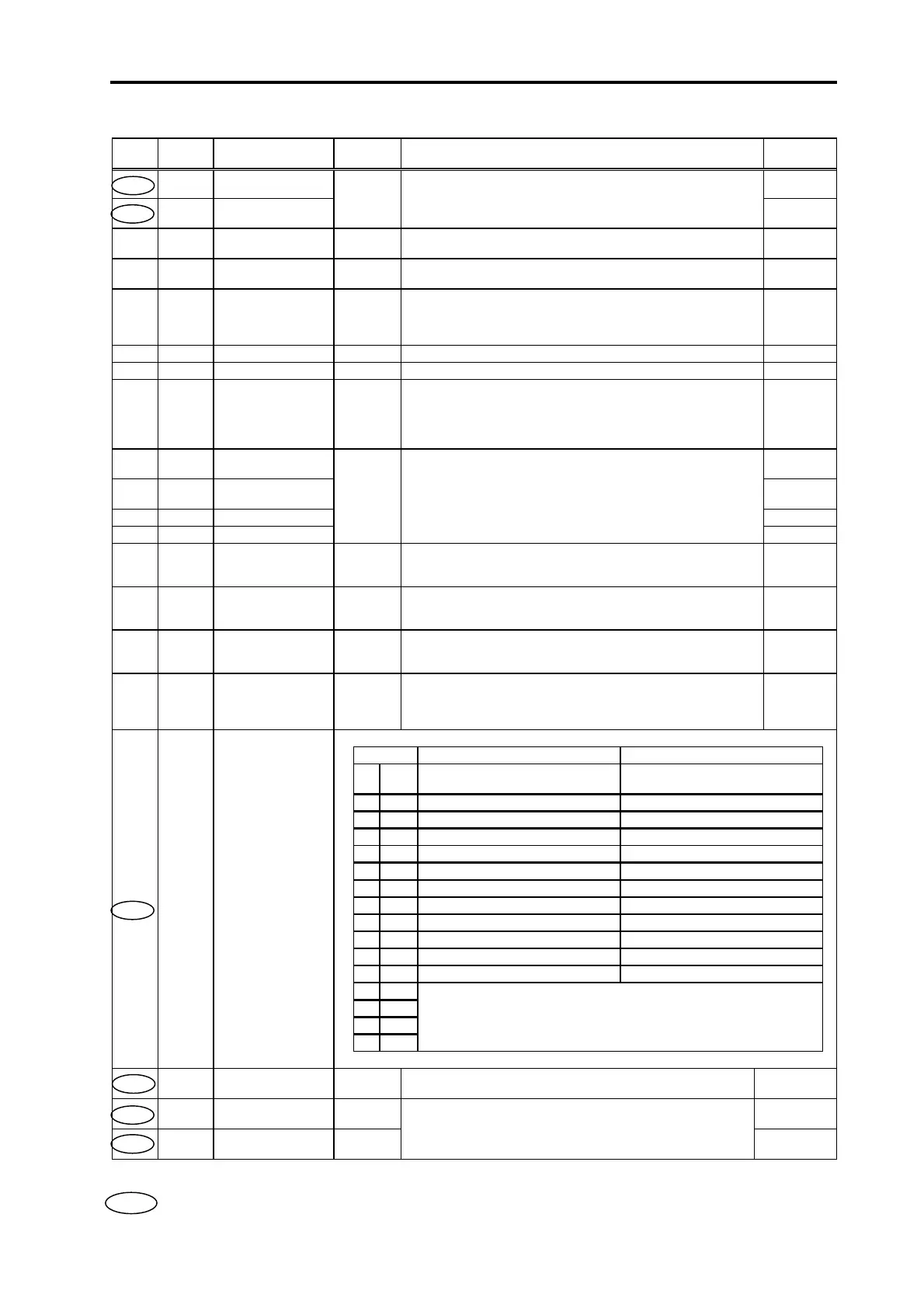

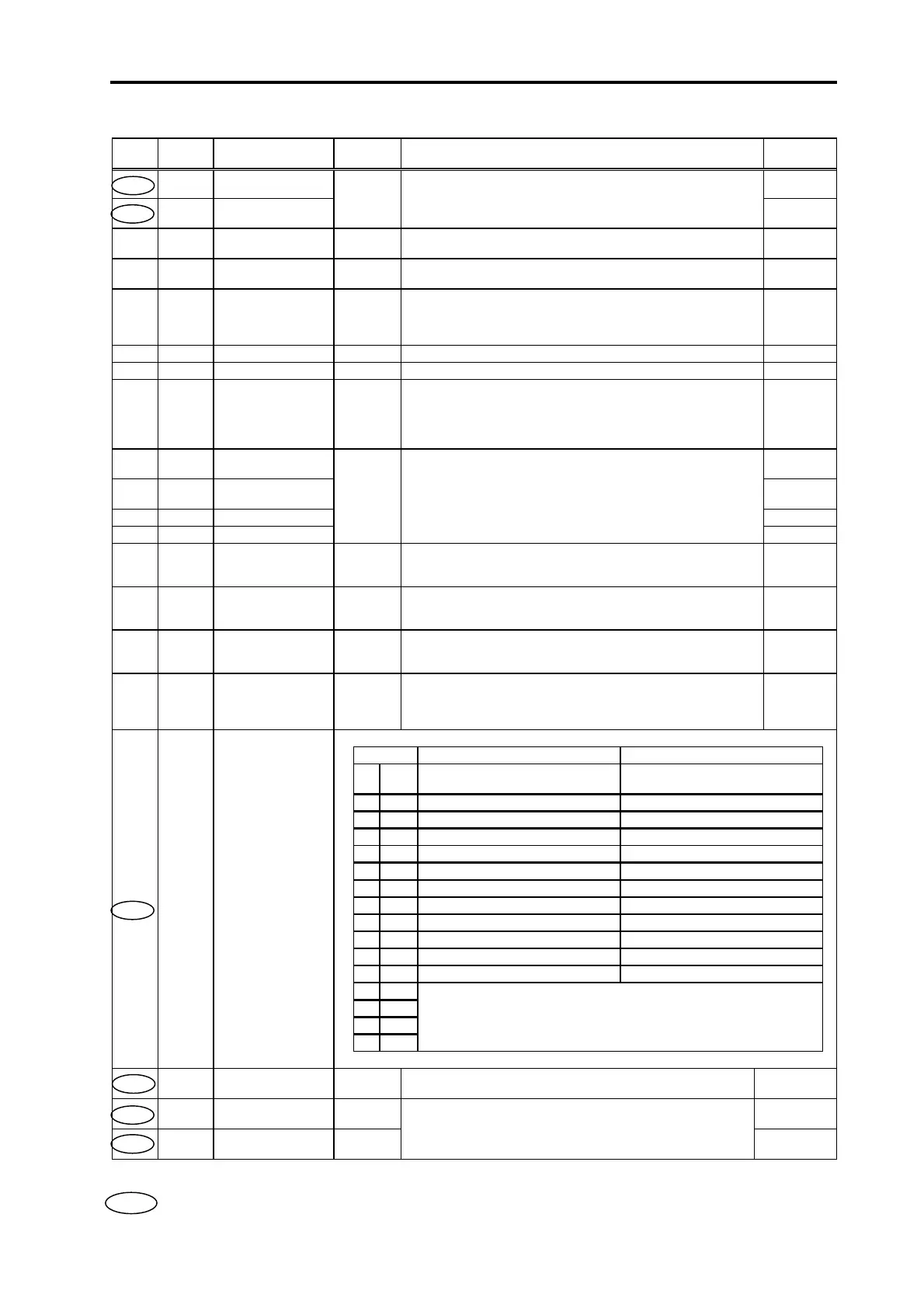

8-6 Parameter list

No. Abbrev. Parameter name Unit Explanation

Setting

range

SV001 PC1 Motor side gear ratio 1 to 32767

SV002 PC2

Machine side gear

ratio

Set the motor side and machine side gear ratio.

For the rotary axis, set the total deceleration (acceleration) ratio.

Even if the gear ratio is within the setting range, the electronic

gears may overflow and cause an alarm.

1 to 32767

SV003 PGN1 Position loop gain 1 rad/sec

Set the position loop gain. Set 33 as a standard.

When using SHG control, also set PGN2 and SHGC.

1 to 200

SV004 PGN2 Position loop gain 2 rad/sec

Set 0 as a standard.

When using SHG control, also set PGN1 and SHGC.

0 to 999

SV005 VGN1 Speed loop gain

Set this according to the motor inertia size.

If motor resonance occurs, lower the value by 20 to 30% at a time.

The setting value should be 70 to 80% of the value where

resonance does not occur.

1 to 999

SV006 Set "0". 0

SV007 Set "0". 0

SV008 VIA

Speed loop leading

compensation

Set 1364 as a standard. During SHG control, set 1900 as a

standard.

Raise this value to improve contour tracking precision in high-

cutting. Lower this value when the position droop vibrates.

Adjust by 100 at a time.

1 to 9999

SV009 IQA

q axis leading

compensation

1 to 20480

SV010 IDA

d axis leading

compensation

1 to 20480

SV011 IQG q axis gain 1 to 2560

SV012 IDG d axis gain

This setting is determined by the motor's electrical characteristics.

Set the standard parameters for all parameters. (These are used

for maker adjustments.)

1 to 2560

SV013 ILMT Current limit value

Stall %

(rated

current %)

Set the standard parameter value. The maximum torque is

determined by the motor specifications.

0 to 500

SV014 ILMTsp

Current limit value

during special

operation

Stall %

(rated

current %)

Set the standard parameter value.

Set the limit torque mainly for the stopper.

0 to 500

SV015 FFC

Acceleration feed

forward gain

%

The standard setting value is 0. For SGH control, set 100.

To improve the acceleration/deceleration characteristics, increase

the value by 50 to 100 at a time.

1 to 999

SV016 LMC1

Lost motion

compensation 1

Stall %

(rated

current %)

The protrusion amount during quadrant changeover is suppressed.

Adjust in 5% units.

When LMC2 is set to 0, the setting value will apply in both the ±

directions.

–1 to 200

bit Meaning when "0" is set Meaning when "1" is set

0 dmk

Deceleration controlo stop selection

(SVJ2 standard)

Dynamic brake stop selection

1

2

3

4

5

6

7 abs Incremental control Absolute position control

8

9

10

11

12 mtc

13

14

15

Motor table selection according to model

Set 0100 for the intelligent servomotor HS Series.

SV017 SPEC Servo specifications

Set "0" in bits with no particular description.

SV018 PIT Ball screw pitch mm

Set the ball screw pitch. Set 360 for the rotary axis.

Refer to the CNC Instruction Manual for the inch ball screw.

1 to 32767

SV019 RNG1

Position detector

resolution

kp/rev 8 to 100

SV020 RNG2

Speed detector

resolution

kp/rev

Set the motor detector resolution for both settings.

Refer to the Standard parameter list per motor for the settings.

8 to 100

SV001 is a parameter validated when the NC power is turned ON again.

Loading...

Loading...