Chapter 7 Setup

7–3

7-1-3 Parameters set according to feedrate

The following parameters are determined according to each axis' feedrate.

No. Abbrev. Parameter name Explanation

SV023 OD1 Excessive error detection

width at servo ON

SV026 OD2 Excessive error detection

width at servo OFF

A protective function will activate if the error between the position command and

position feedback is excessive. If the machine load is heavy and problems occur

with the standard settings, gradually increase the setting value.

<Calculation of standard setting value>

OD1 = OD2 =

Rapid traverse rate (mm/min)

60

×

PGN1

÷ 2 (mm)

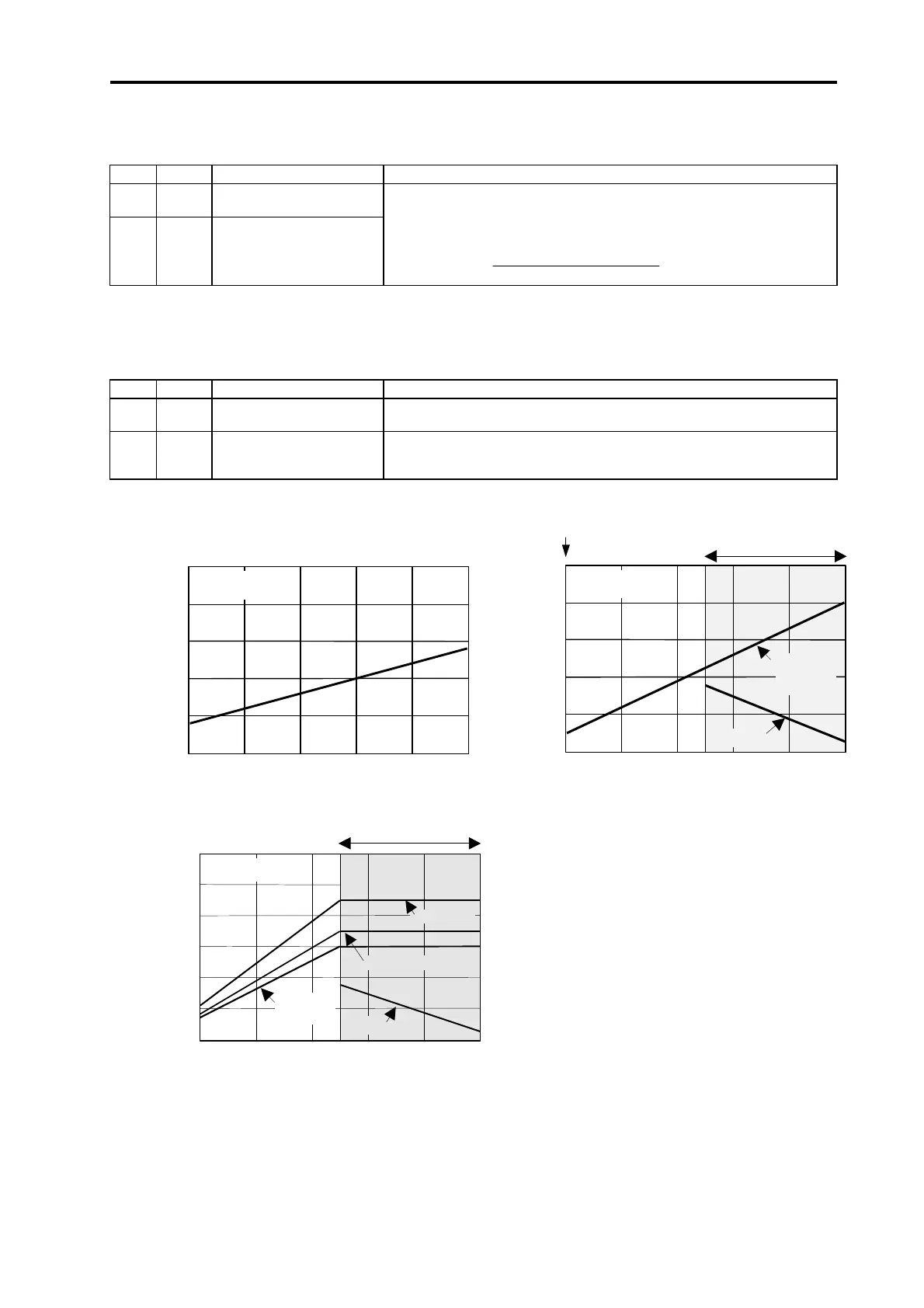

7-1-4 Parameters set according to machine load inertia

The following parameters are set according to the machine's inertia.

No. Abbrev. Parameter name Explanation

SV005 VGN1 Speed loop gain. Refer to the comparison graph with the load inertia scale for the standard setting

value.

SV008 VIA Speed loop leading

compensation

Set 1364 as a standard. Set 1900 as a standard for the SHG control.

If the load inertia is large and is in the standard VIA change region, set the value in

the comparison graph regardless of whether normal control or SHG control is used.

Load inertia scale (total load inertia/motor inertia)

Standard

VGN1

Motor single unit

1

3 7

11

5 9

<HS-RF>

HC-RF43

HC-RF73

1500

1000

500

VIA

VIA

Standard VIA change region

20

40

0

100

80

60

Load inertia scale (total load inertia/motor inertia)

Standard

VGN1

1

3 7

11

5 9

<HS-MF>

10

20

0

50

40

30

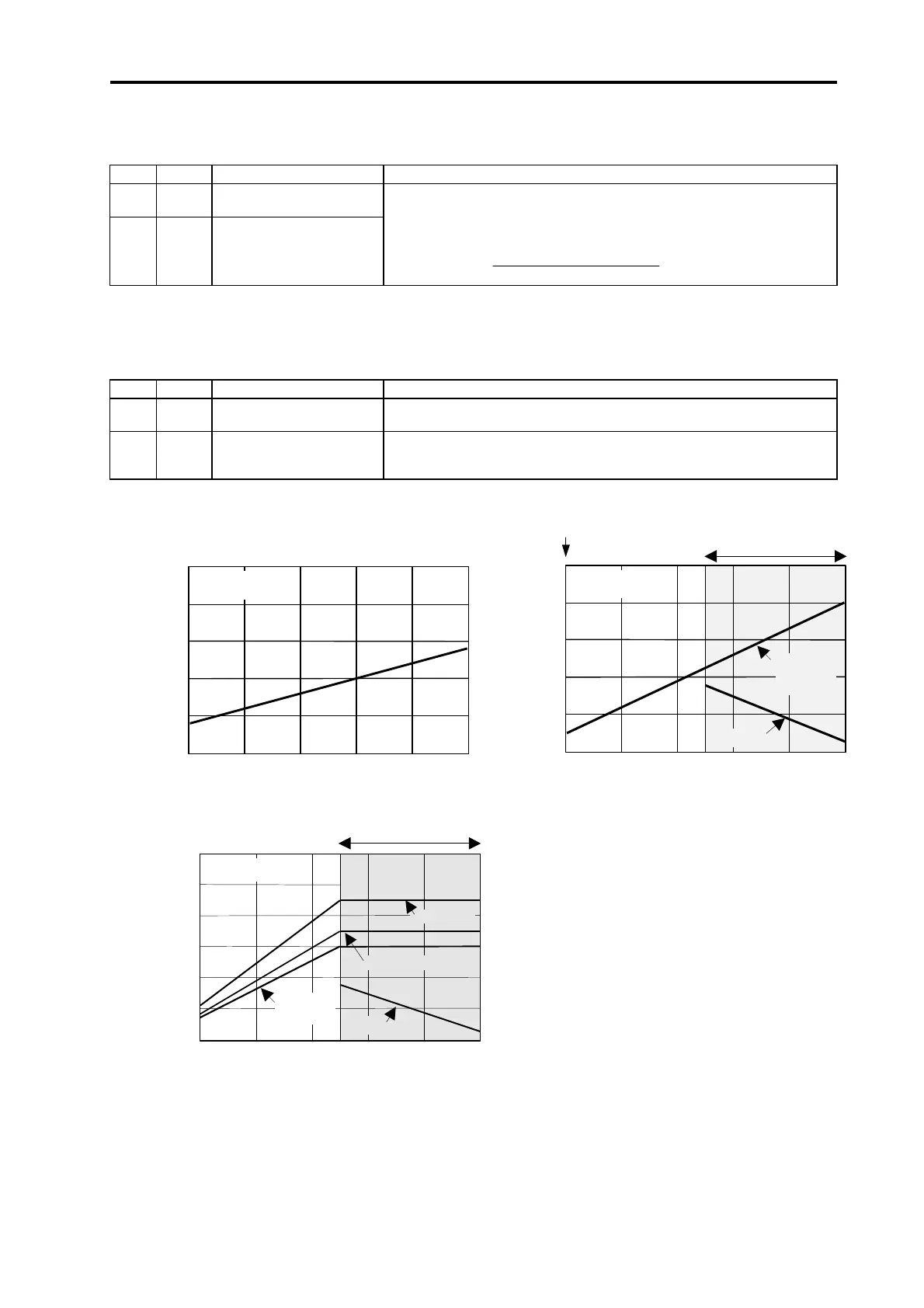

Load inertia scale (total load inertia/motor inertia)

Standard

VGN1

0

600

100

200

500

400

300

1500

1000

HC-SF52

HC-SF102

HC-SF202

500

VIA

VIA

<HC-SF>

HC-SF53, HC-SF103

Standard VIA change region

Loading...

Loading...