4 of 8

SAFETY INSPECTION - MAINTENANCE

Your product is a precision product - proper care will ensure proper function. Regular

cleaning will reveal loose or worn parts. DO NOT over tighten parts or hardware,

as doing so can damage the frame. DO NOT operate the product if there are any

missing parts or hardware. You should have a dealer or qualied professional perform

maintenance on your product at least once every six months, or immediately if you

notice any item needing service. Frequent use likely means that your product will

require more maintenance than we suggest. In anticipation of and after any excessive

use, we recommend that you perform a complete safety inspection including all items.

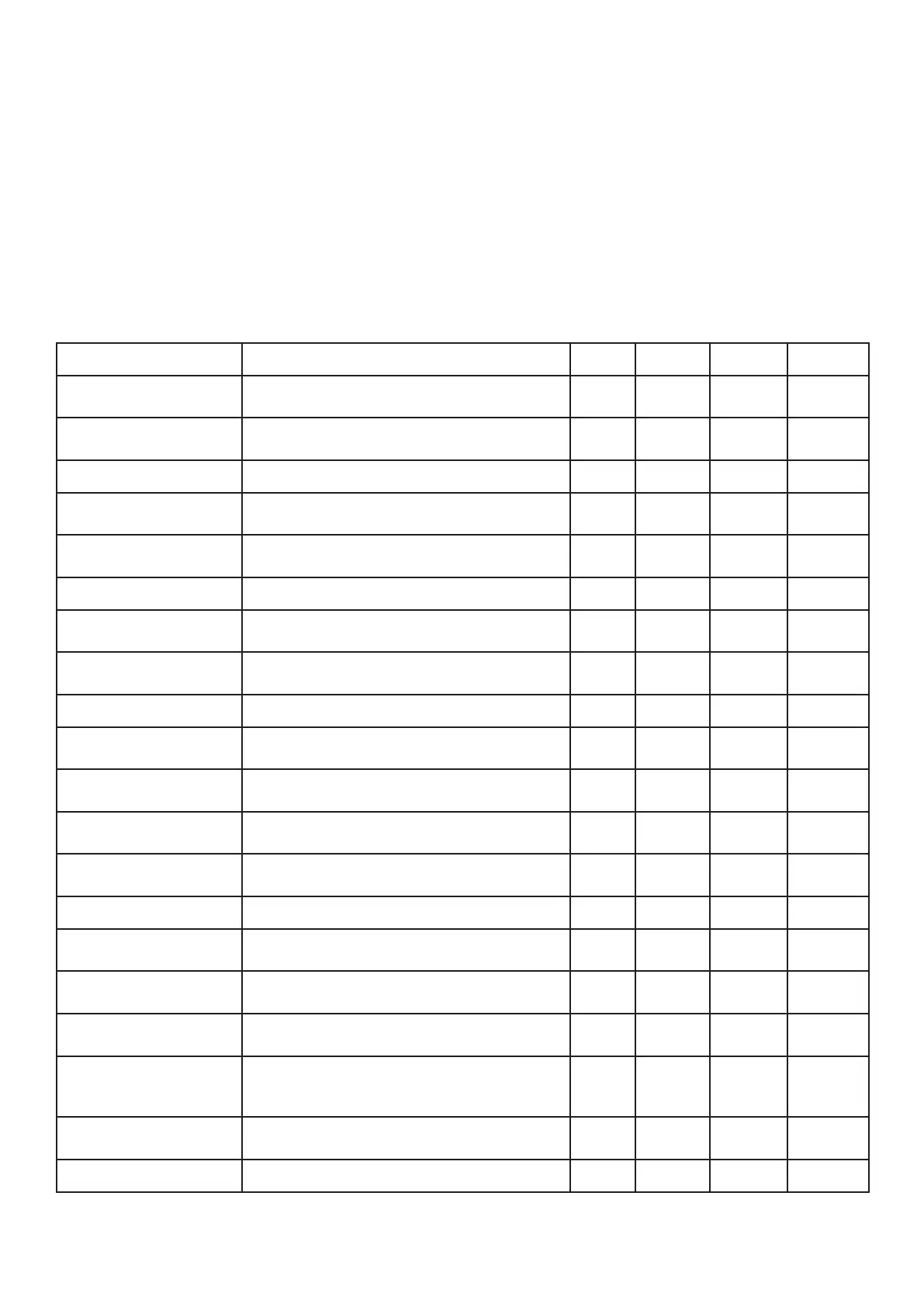

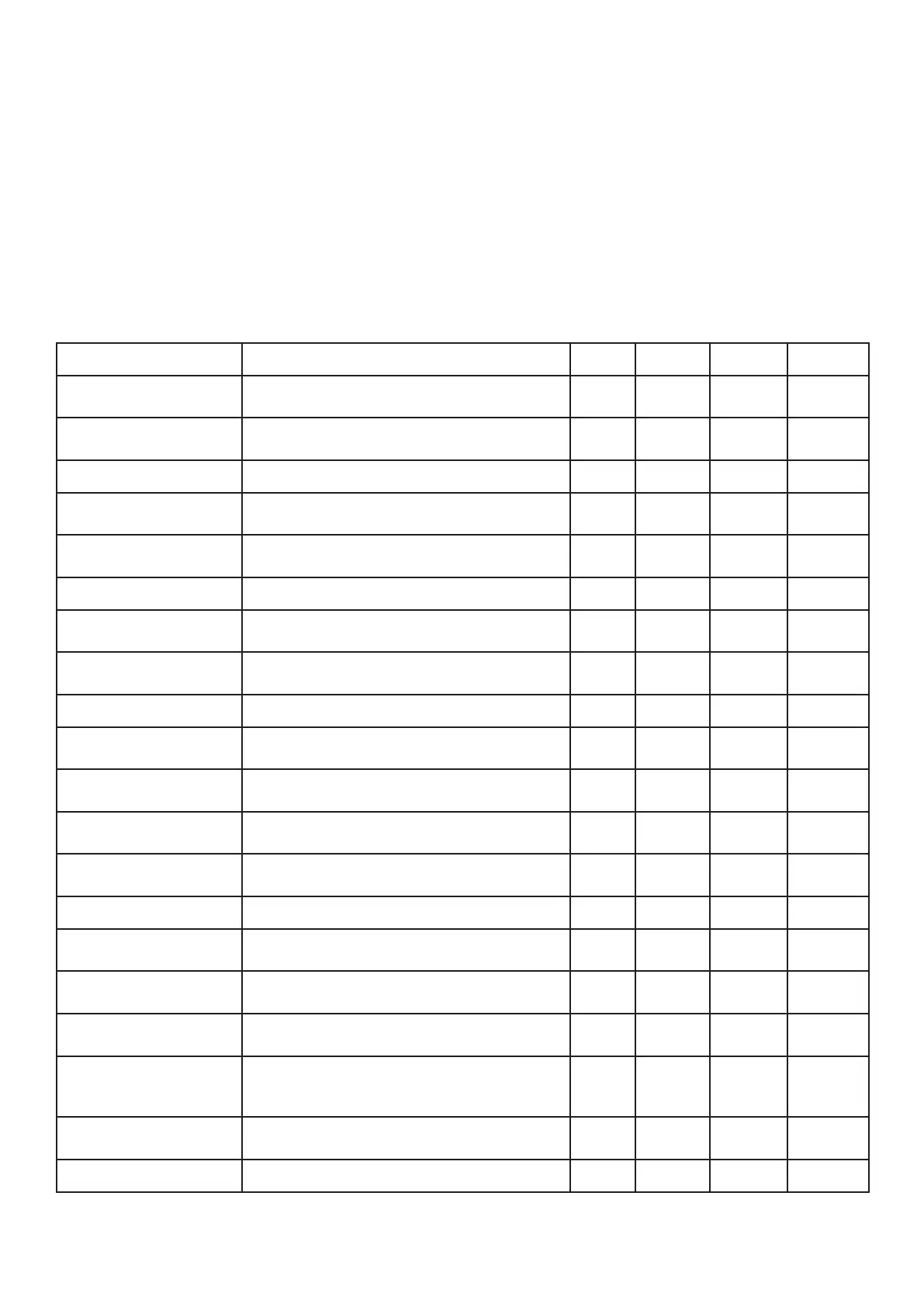

ITEM INSPECT ITEM INITIAL WEEKLY MONTHLY 6 MONTHS

GENERAL

Knee walker should roll straight, doesn't

feel "tight" or pull to one side

X X

Inspect for loose, missing, or broken

hardware in all locations

X X

FRAME Inspect for bent frame X X

Inspect weld points for cracks, chips, or

loose material

X X

BRAKES

Ensure brakes do not interfere with

wheels when rolling

X X

Pivot points free of wear and looseness X X

Brakes are easy to engage, and engage

fully. Adjust tension screws as necessary

X X

Examine brake pads for excessive wear,

and rotate, if necessary.

X X

Replace brake pads, if necessary X

Inspect for loose or broken hardware on

hand brakes and brake shoes

X X

WHEELS

Lift, spin, and check for side movement,

rubbing, or binding

X X

Check wheels for excessive wear and

replace or rotate them, as needed.

X X

Inspect for cracks and wear (hubs and

rims)

X X

Inspect for cracked or broken spokes X X

Check wheel axle bolts to ensure they

are secure.

X X

Adjust bearing system if wheel wobbles

noticeably or binds to a stop

X X

Ensure wheel bearings are clean and

free of debris

X X

KNEE PAD

Clean knee pad using a non-abrasive

cloth with a mild detergent and water

then sanitize with sanitizing solution

X X

Check knee pad for excessive wear,

cracks, rips or tears, or damage

X X

Replace knee pad, if necessary X

Loading...

Loading...