Outputting Data and Controlling Operation through EtherNet/IP

FQ2-S4 User’s Manual

331

Connecting through Ethernet

9

FQ2 Communications for EtherNet/IP Connections

You can use EtherNet/IP tag data links to communicate between the PLC and the Vision Sensor to perform

control via command/response communications or to output data after measurements.

The FQ2 complies with EtherNet/IP conformance test version A8.

To connect to OMRON Controllers and communicate through EtherNet/IP, you use the Network Configurator to

set up tag data links (i.e., tags, tag sets, and connection settings).

Refer to the following manuals for details on the tag data link settings that are made with the Network

Configurator.

• NJ-series CPU Unit Built-in EtherNet/IP Port User’s Manual (Cat. No. W506)

• CS/CJ-series EtherNet/IP Units Operation Manual (Cat. No. W465)

• CJ-series EtherNet/IP Units Operation Manual for NJ-series CPU Unit (Cat. No. W495)

Types of Communications

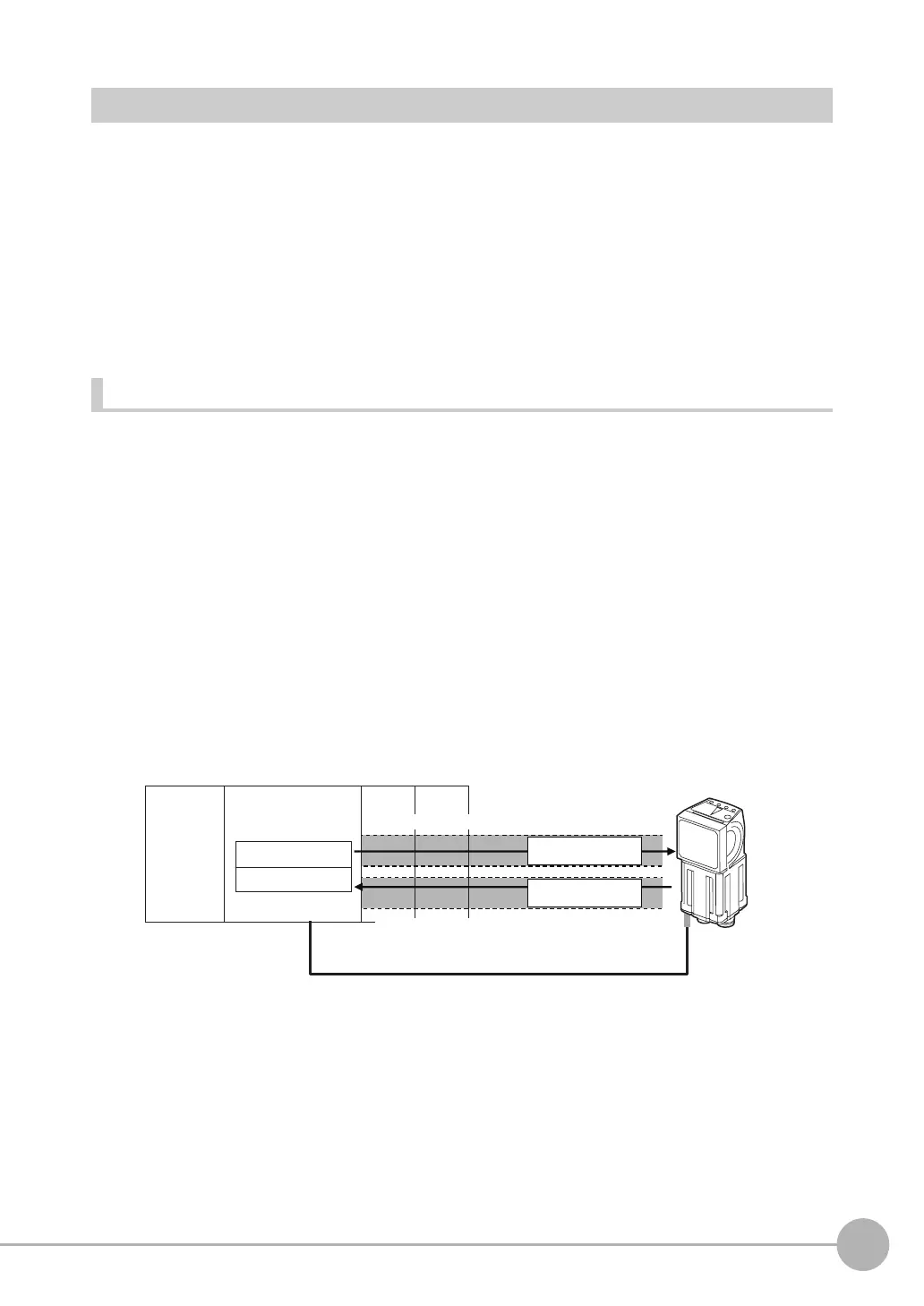

● Command/Response Communications

With EtherNet/IP communications, cyclic tag data link communications are performed with the connections that

are set between the PLC and Vision Sensor.

Command/response control signals are handled by storing control commands from the PLC to the Vision

Sensor and responses from the Vision Sensor to the PLC in the I/O memory of the PLC.

This allows you to control the operation of the Vision Sensor (e.g., perform continuous measurements or

change the scene) without using special communications instructions.

• Input Connection to Sensor (PLC to Vision Sensor)

The commands that are stored in the I/O memory of the PLC are sent to the Vision Sensor.

• Output Connection to PLC (Vision Sensor to PLC)

Responses from the Vision Sensor to the control commands are stored in the PLC I/O memory addresses or vari-

ables that are specified for the response area.

To send a control command, you write a control command to the command area (i.e., a variable or I/O memory

address in the PLC) that is specified for the output tag, and then turn ON the Command Execution (EXE) Bit.

As a result, the control command is sent through the input connection from the PLC to the Vision Sensor.

A control command does not need to be sent to execute measurements for the TRIG bit.

The measurement is executed simply by turning ON the TRIG bit.

The Vision Sensor executes the control command and sends a response back to the PLC through the output

connection from the Vision Sensor to the PLC.

The PLC stores the response in the response area (i.e., I/O memory addresses or variable) that is specified for

the input tag in the PLC.

PLC

Vision Sensor

Command area

Response area

I/O memory or variables

(communications areas)

CPU Unit

EtherNet/IP (tag data links)

OK, etc.

• Continuous measurements

•

Switching the scene number, etc.

Command

Response

Input connection to Sensor

Output connection to PLC

Loading...

Loading...