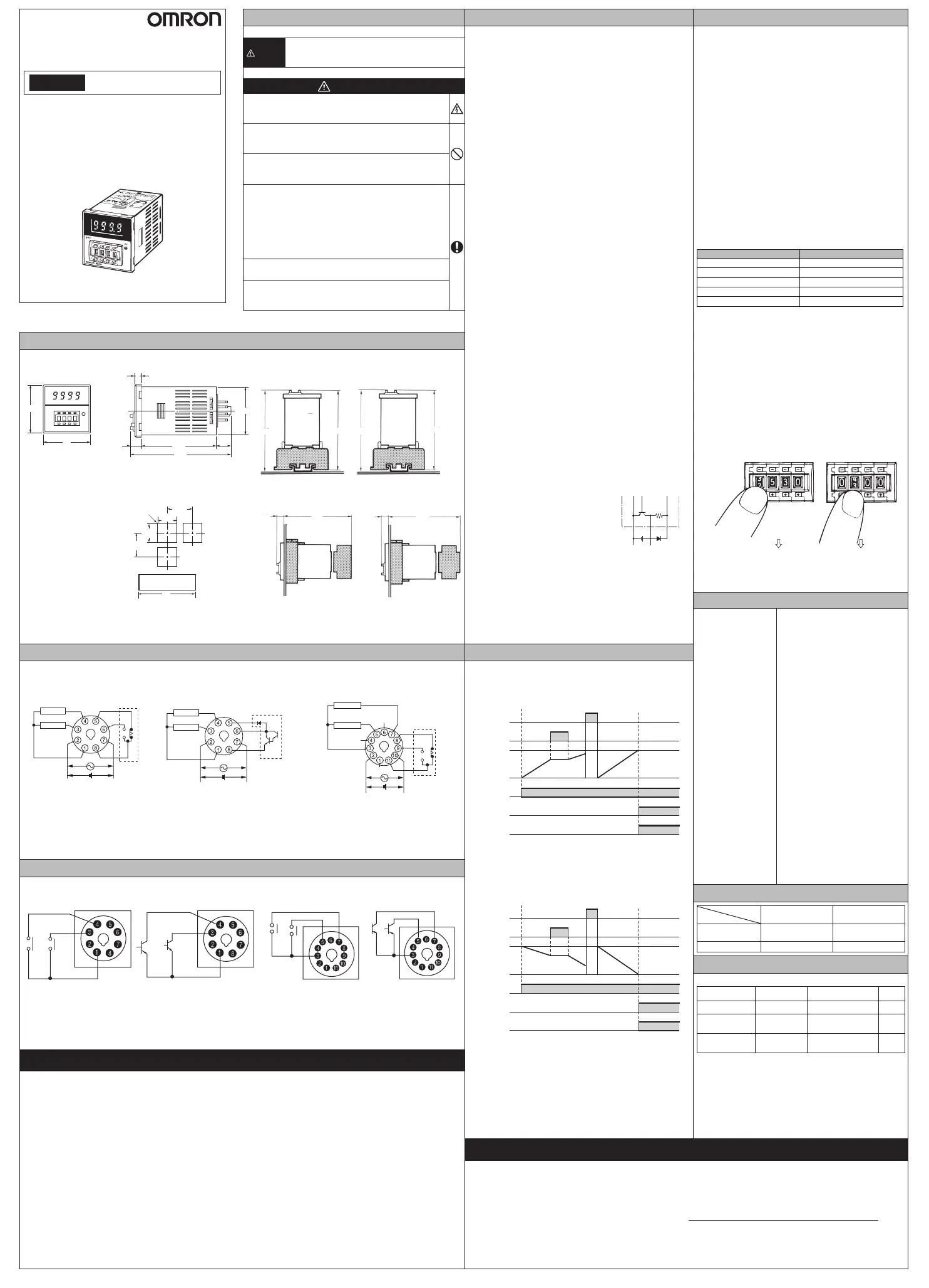

Dimensions and Installation

n DIMENSIONS

[mm]

5.27

(10.9)

14.2

97.6

6

@44.8

48

48

n PANEL CUTOUT [mm]

60 min.

Standard panel cutout is as

shown in the right gure.

(conforms to DIN43700)

Note 1. The thickness of

mounting panel

should be 1 to 5 mm.

Note 2. It is possible to

mount the products

side-by-side. The di-

mension is as shown

in the right gure.

45

㧗0.6

㧙0

㧗0.6

㧙0

45

A

A=(48n-2.5)

+1

-0

n Units mounted

side-by-side

R0.5 max.

60 min.

n INSTALLATION [mm]

Surface mounting

Model H5CN

-@@N

-X@NS

P2CF-08(-E) P2CF-11(-E)

Model H5CN

-X@NM

Flush mounting

Model H5CN

-@@N

-X@NS

+

Adapter

Model H5CN

-X@NM

+

Adapter

P3G-08

Y92F-30

P3GA-11

Y92F-30

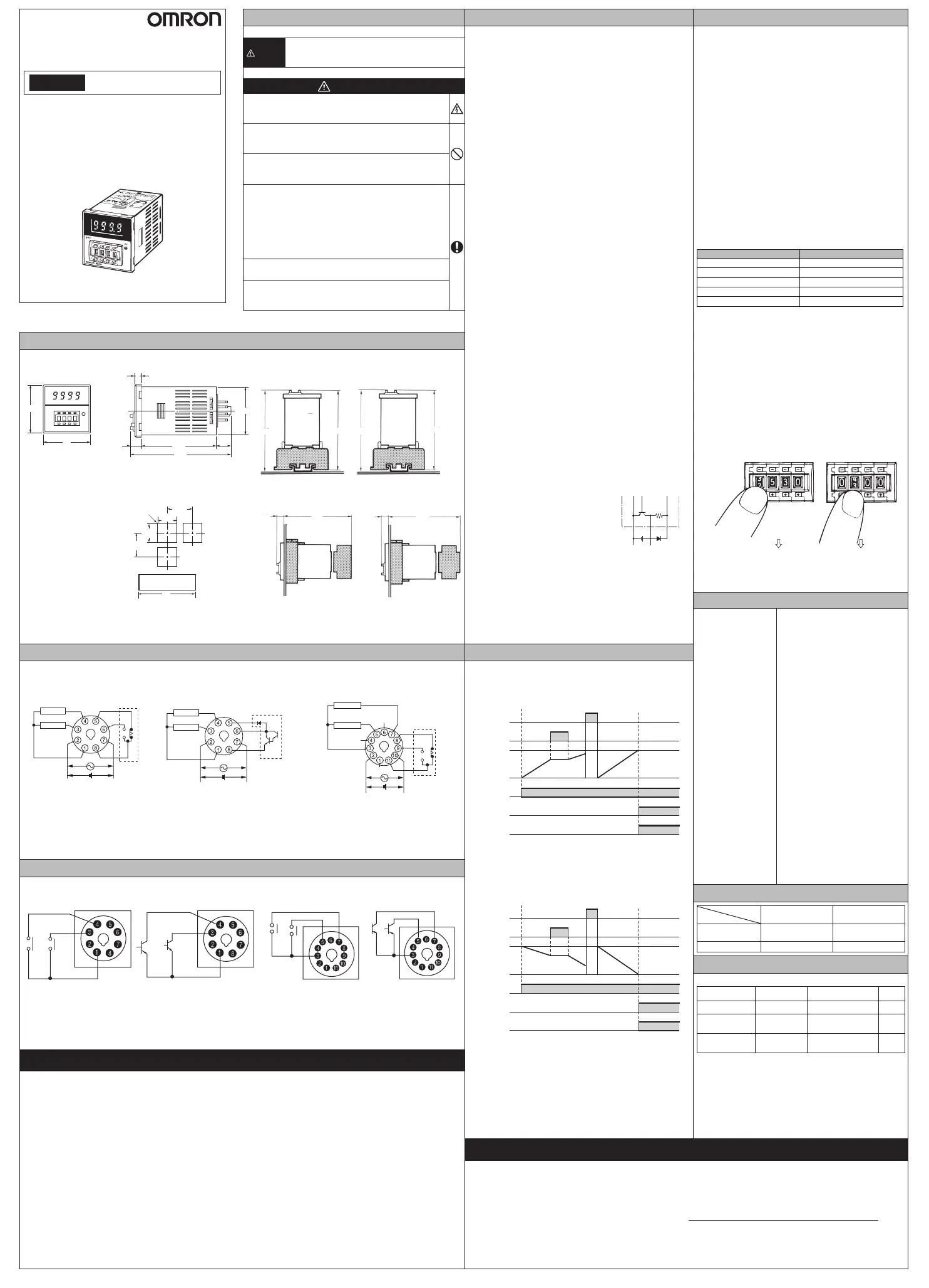

Connection

● Model H5CN-@@N

(without memory backup)

Contact output

● Model H5CN-X@NS

(without memory backup)

Transistor output

● Model H5CN-X@NM

(with memory backup)

Contact output

Contact

output

Gate

Internal circuit

Contact

output

100 to 240 VAC

12 to 48 VDC

Reset

Gate

Internal circuit

Transistor

output

100 to 240 VAC

12 to 48 VDC

Reset

Gate

DO NOT USE

DO NOT

USE

Internal circuit

100 to 240 VAC

24 VDC

Reset

DO NOT

USE

▪ Model H5CN-@@N/X@NS: Terminal 1 is internally connected to terminal 2 if the Counter is a model that operates with DC.

Model H5CN-X@NM: Terminal 3 is internally connected to terminal 2 if the Counter is a model that operates with DC.

▪ A diode is connected between terminal 5 and 6 to absorb the counter electromotive force that occurs when connecting an

inductive load.

▪ Do not wire the terminals which are not used.

Input Connection

● Model H5CN-@@N/X@NS (without memory backup)

Gate input

Reset input

Gate input

Reset input

Connection of contact signal input Connection of transistor signal input

● Model H5CN-X@NM (with memory backup)

Connection of contact signal input

Connection of transistor signal input

Gate input

Reset input

Gate input

Reset input

Suitability for Use

OMRON Companies shall not be responsible for conformity with any standards, codes or regulations which apply to the combina-

tion of the Product in the Buyer’s application or use of the Product. At Buyer’s request, OMRON will provide applicable third party

certication documents identifying ratings and limitations of use which apply to the Product. This information by itself is not sufcient

for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other ap-

plication or use. Buyer shall be solely responsible for determining appropriateness of the particular Product with respect to Buyer’s

application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY OR IN LARGE

QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND

THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

Precautions for Safety Use

Please comply strictly with the following instructions which are

intended to ensure safe operation of thecontroller

.

1)

Make sure the proper product is specied for the application

.

2) For correct use, do not subject the product to the following

conditions.

• Dramatic temperature uctuations

• High humidity or where condensation may occur

• Severe vibration and shock

• Where excessive dust, corrosive gas, or direct sunlight may

be present

3) This product is not waterproof or oil resistance. Do not use the

product in any of the places subject to splashing liquid or oil

atmosphere.

4)

Use and store the product within the rated ranges given for the

product model you are using. If necessary, use forced cooling

.

If the product is stored below −10°C, allow it to warm up for three

hours at room temperature before turning ON the power supply

.

5) Do not cover the vent holeson the products and the area

around the product in order to ensure thermal dissipation.

6) Wiring all terminals correctly.

7) Do not wire the terminals which are not used.

8)

Use specied size crimped terminals (M3.5, thickness 7.2 mm

max.) for wiring with a gage of AWG 24 to AWG 18 (equal to a

cross section area of 0.205 to 0.823 mm

2

).

(The wiring stripping length is 5 to 6 mm.)

Up to two wires of same size and type, or two crimped termi-

nals can be inserted into a single terminal.

9) Use this product within the rated power supply voltage and

control output.

10)

Use a switch, relay, or other contact to turn the power supply

ON instantaneously. If the voltage is applied gradually, the

power may not be reset or output malfunctions may occur

.

11) Do not apply the supply voltage directly from external to

transistor output.

12) Install and clearly label a switch or circuit breaker so that the

operator can quickly turn OFF the power supply.

13) Install the input signal resource and the product itself apart

from noise generating sources and wiring which is carrying

the high power current to cause noise.

14) Separate the product from any sources of excessive static

electricity, such as forming materials and pipes carrying

powder and liquid materials.

15) Interlock the power to the product with a relay so that the

product will not be left in an output on condition for long peri-

ods. Leaving the product in an output-on condition for a month

or longer, especially in places with high temperatures, may

result in deterioration to internal parts, such as an electrolytic

capacitor.

16)

Internal circuit voltage (5 V) is output to the no-voltage input

terminals, which may cause some connected devices to

malfunction or fail. Check the specications of the input device

(e.g., rated output voltage or whether a power supply circuit

diode is built in)

.

To prevent power supply devices from

being subjected to charging accidents,

connect a diode as in the gure when

using a power supply voltage of 5 V or

less to operate input devices that do

not have a diode built into the power

supply circuit.

17) The exterior of the product may be damaged by organic sol-

vents (such as thinners or benzene), strong alkali, or strong

acids.

18)

Check that the LED indicators are operating normally. Depending

on the operating environment, the indicators and plastic parts may

deteriorate faster than expected, causing the indicators to fail.

Periodically perform inspections and replacements

.

19) Use tools when separating parts for disposal.

20) When disposing of the product, observer all local ordinances

as they apply.

Sensor

Input

Model H5CN

DIGITAL TIMER

English INSTRUCTION MANUAL

Thank you for purchasing this OMRON product.

This manual primarily describes the functions, performance and

application methods needed for optimum use of the product.

Please observe the following items when using the product.

▪ This product is designed for use by qualied personnel with a

knowledge of electrical systems.

▪ Before using the product, thoroughly read and understand this

manual to ensure correct use.

▪ Keep this manual in a safe location so that it is available for

reference whenever required.

OMRON Corporation

©All Rights Reserved

2288978-2A (Side-B)

Safety Precautions

l Key to WARNING Symbols

CAUTION

Indicates a potentially hazardous situation which, if

not avoided, is likely to result in minor or moderate

injury or property damage.

l Warning Symbols

CAUTION

Do not touch the terminals while power is being supplied.

Doing so many occasionally result in minor injury due to

electric shock.

Do not use the product where subject to ammable or

explosive gas.

Otherwise, minor injury from explosion may occasionally occur

.

Never disassemble, modify or repair the product or touch

any of the internal parts. Minor electric shock, re, or

malfunction may occasionally occur.

The life expectancy of output relays varies considerably

with the output load and switching conditions. Always con-

sider the application conditions and use the output relays

within their rated load and electrical life expectancy. If the

output relays are used past their life expectancy, contact

fusing or burning may occasionally occur. Also, never

exceed the rated load current. When using a heater, surely

use a thermo switch in the load circuit.

Tighten the terminal screws to between 0.74 and 0.90 N·m.

Loose screws may occasionally result in re.

Do not allow pieces of metal, wire clippings, or ne metallic

shavings or lings from installation to enter the product. Doing

so may occasionally result in electric shock, re, or malfunction

.

Set the reset time at lease 0.5 sec during power recovery (power reset).

Timing Chart (Power ON Delay)

● Digital display

UP Display

Reset input

Time up

indication

Control output

Power supply

Digital display

Setting value

Gate input

Power ON

Time UP

no digital

display

DOWN Display

Reset input

Time up

indication

Control output

Power supply

Digital display

Setting value

Gate input

Power ON

Time UP

no digital

display

Contact Address

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp The Netherlands

Phone 31-2356-81-300

FAX 31-2356-81-388

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg, IL 60173-5302 U.S.A

Phone 1-847-843-7900

FAX 1-847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08(Lobby 2),

Alexandra Technopark, Singapore 119967

Phone 65-6835-3011

FAX 65-6835-2711

OMRON Corporation

Shiokoji Horikawa, Shimogyo-ku, Kyoto 600-8530 JAPAN

Precautions for Correct Use

1) Inrush current will be carried when turning on the power.

If the capacity of the power for the product is insufcient,

the product cannot start. Use a power supply, breakers,

contacts which sufcient capacity.

100 to 240 VAC specications

Approx. 0.8 A for 264 VAC

12 to 48 VDC specications Approx. 0.4 A for 52.8 VDC

2)

Since 50 ms after the power is turned ON is required as the raise

time of the internal circuit voltage, note that the product may not

operate in response to any input signal during this period

.

3) Since100 ms after the power is turned OFF (or momen-

tary power failures) is required as the fall time of the

internal circuit voltage, note that the product may respond

to input signals during this period

.

4) The product memorizes the status just before occurring

the electric failure memory with non-volatile memory. The

rewriting lifespan of the non-volatile memory is 1,000,000

or more. The non-volatile memory rewrites the setting

condition into the initial setting one when the power OFF

and reset input. (-M type only)

5)

Model H5CN 12-48 VDC specication use transformer-less

power supply which the power terminals and input terminals are

not insulated. When use this specication, the internal parts of

the product may be occasionally burnt (damaged) if the wiring

is not correct. Pay attention to check the wiring before use

.

6) Operation time setting

Time setting range

Setting range Model

0.001 sec~9.999 sec

H5CN-@Z@

0.01 sec-99.99 sec

H5CN-@A@

0.1 sec-999.9 sec

H5CN-@B@

1 sec-99min59 sec

H5CN-@C@

1 min-99h59 min

H5CN-@D@

▪

The H5CN Timer is capable of reading the input data at any time dur-

ing normal operation. This means that the set time can be changed

during power application. This feature sets back the output from the

timer by temporarily setting the longer time or quickens the output by

setting the shorter time. During normal operation, the set time may

be accidentally changed by touching a thumbwheel switch, causing

the timer to operate with a different set time. To prevent this possibil-

ity, use the optional Y92A-48B Protective Cover.

▪

When the set time is all zeroes (e.g., 000.0 s or 00 h 00 min), there will

be a momentary control output upon power application, which can be

used to check normal output. When changing the set time during nor-

mal operation, pay attention not to alter the set value to this all zeroes

.

▪

When changing the set time while power is being supplied, an inade-

quate push of the thumbwheel switches willdisplay two numbers in one

display window, causing the operating count to drift widely. Therefore,

press the thumbwheel switches surely. Take particular care when the

other three digits are all zeroes, because the improper setting of the

fourth switch to create four zeroes will cause an instantaneous output

.

(Undesirable

changes in

the settings)

(Conceivable

operating time)

00 h 00 min

(instant output)

5 min 30 s

min minhourssec

▪ Take particular care with the H5CN-@Z@, which is capable

of setting in 1/1000th of a second because there is an error

of between 0.03 to 0.05 s. (Repeat accuracy is 1 to 2 ms)

Specications

Power supply voltage 100 to 240 VAC 50/60 Hz

12 to 48 VDC, 24 VDC

(20% max. ripple)

Operating voltage range

85 to 110% of rated power voltage

Power consumption Approx. 12 VA (for 240 VAC)

Approx. 2.5 W (for 48 VDC)

Reset, gate

Power reset 0.5 sec reset time (min.)

Reset time following power applica-

tion: 0.05 sec

External reset, gate

0.02 sec reset signal width (min.)

ON residual voltage: 2 V max.

* Contact and transistor signal input

use common terminal.

Control output

Contact output

250 VAC 3 A resistive load (cosφ=1)

Minimum load

10 mA, 5 VDC (P level, reference value)

Transistor output open collector

100 mA, 30 VDC max.

Operating ambient

temperature

-10 to +55 ºC

(with no icing and condensation)

Operating ambient humidity

35 to 85% RH

Storage temperature -25 to +65 ºC

(with no icing and condensation)

Altitude 2,000 m max.

Weight Approx. 110 g

Electrical lifespan of

relay

100,000 operations min.

(3 A, 250 VAC resistive load)

Mechanical lifespan of relay

10,000,000 operations min.

Connecting Sockets

SOCKET

H5CN

Surface mounting Flush mounting

-@@N

-X@NS

P2CF-08(-E) P3G-08

-X@NM

P2CF-11(-E) P3GA-11

Self-diagnosis Function

When an error has occurred, the bellow error codes are shown

.

7 segment display Time UP display

Description Output

e1

OFF CPU error OFF

e2

OFF

Memory error

(RAM)

OFF

e3

OFF

Memory error

(non-volatile memory)*

OFF

* Including the case when the rewriting lifespan of the non-

volatile memory is reached.

Recovery method

As an action, turn the power OFF then back ON again. If the dis-

play restored to normal, then a probable cause can be external

noise affecting the system. Check for external noise. In the case

of E3, input gate (“0000” will be displayed) and turn power ON

again. After that, if it still remains the same, the product must

be repaired.

H5CN_CN-EN.indb 2 1/16/2014 11:33:06 AM

Loading...

Loading...