-3-

-4-

1. Hold the button (minimum 3 and less than 5 seconds) until [ ] blinks

without a workpiece.

2. When [ ] starts blinking, release the button.

The display changes [ ] [ ] and 1-point tuning is completed.

The measured value display returns.

Used to judge the presence/absence of a workpiece by referring to the pre-determined

background (reference surface).

Used to assign the upper and lower limits to one actual workpiece and judge

if the workpiece is within the range.

●

1-point Tuning

2. Hold the button (3 to less than 5 seconds) until [ ] blinks with a workpiece

to detect on the reference surface.

1. Set the AREA item in the menu to "ON" and return to the measured value display.

3. When [ ] starts blinking on the display,

release the button.

●

1-point Area Tuning

(3) Detect for Workpiece Presence/Absence

(Tuning Only Using Reference Surface)

(5) Set Plus/Minus (±) Tolerance

●

Threshold Value Setting

The OUT1 indicator keeps blinking while "Threshold 1/ Threshold 1H/ Threshold 1L"

is being changed.The OUT2 indicator keeps blinking while "Threshold 2/ Threshold

2H/ Threshold 2L" is being changed.

(

2

)

Detect for Workpiece Presence/Absence

1. Press the button (within 1 sec.) once without a workpiece.

3. Set the workpiece at the desired lower limit and lightly press the button.

To loosen or tighten the ON/OFF switching conditions, use the buttons for

minute adjustment of the threshold values.

The order of the workpiece does not matter.

Used to distinguish between two objects with different height from the Sensor e.g.

OK and NG, workpiece and background (reference surface) or workpieces A and B.

●

2-point Tuning

2. Lightly press the button once again with a workpiece.

The display changes [ ] [ ]

and 2-point tuning is completed.

The measured value display returns.

The order of the workpiece does not matter.

Increase threshold

Decrease threshold

Refer to " 7. Area Output, Detailed Settings"

To set plus and minus threshold values using "0" as the background, use the zero

reset function to reset the distance to "0". Then, perform 1-point area tuning.

The display changes [ ] [

t-p1

] [ ].

0.00

Hold for 3 to

less than 5 sec

until [ ] blinks.

TUNE

TUNE

TUNE

TUNE

TUNE

TUNE

TUNE

UP/DOWN

t-p1

t-p2

Setting is Completed

t-p1

Setting is Completed

t-p2

The display changes [ ] [ ] and 2-point tuning is completed.

The measured value display returns.

Setting is Completed

Hold for 3 to

less than 5 sec

until [ ] blinks.

t-p1

Setting is Completed

Refer to "

Convenient Setting Features (1)"

Refer to " Error Messages" .

2. The channel display changes in the following sequence

by pressing the button.

3. Press the button to return to measurement mode.

1. Briefly press the button in Measurement

mode.

●

CH Setting Mode

(

1

)

Switch Channel to Set Threshold

ch-1

ch-2

ch1h

ch1l

ch2h

ch2l

<Area Output is ON>

Threshold 1 Threshold 2

Threshold 1H Threshold 1L Threshold 2H Threshold 2L

ch-1

0.00

UP/DOWN

UP/DOWN

MODE

1. Hold the button (5 sec. or longer) until [ ] blinks rapidly without a workpiece.

(6) When (2) to (5) Methods Failed

Used to judge the presence/absence of a workpiece using the pre-determined background

(reference surface) as the reference. Unlike 1-point tuning, this method focuses on the detection

of the absence of workpiece. Insufficient light level or outside-range errors caused by

complicated workpiece appearance are judged as "the presence of the workpiece".

Used to assign the upper and lower limits to the distance from the reference surface and judge

if a workpiece is within the range. Unlike 2-point tuning, this method focuses on the detection of

the absence of workpiece. Insufficient light level or outside-range errors caused by complicated

workpiece appearance are judged as "the presence of the workpiece".

2. When [ ] in the display starts blinking rapidly, release the button.

●

Tuning mode without Workpiece (Area Output is OFF)

●

Tuning mode without Workpiece (Area Output is ON)

Threshold H

Threshold

Threshold L

Reference surface

Reference surface

ON

OFF

OFF

ON

ON

<Tuning mode without Workpiece> <Area Tuning mode without Workpiece>

TUNE

TUNE

Sensor Sensor

Hold for 3 to

less than 5 sec

until [ ] blinks

rapidly.

Setting is Completed

1. Select "ON" for area output in menu setting mode to return to measurement mode.

●

2-point Area Tuning

2. Set the workpiece at the desired upper limit and lightly press the button.

(4) Set Upper Limit and Lower Limit (Using Area Output)

Refer to " 7. Area Output, Detailed Settings"

Used to judge if the workpiece is within the range by using the upper limit and

lower limit workpieces.

TUNE

t-p1

The display changes [ ] [

t-p1

] [ ].

pnt 2

Fine Adjustment of Threshold Value

2-4

③

Settings

2

Tuning

2-3

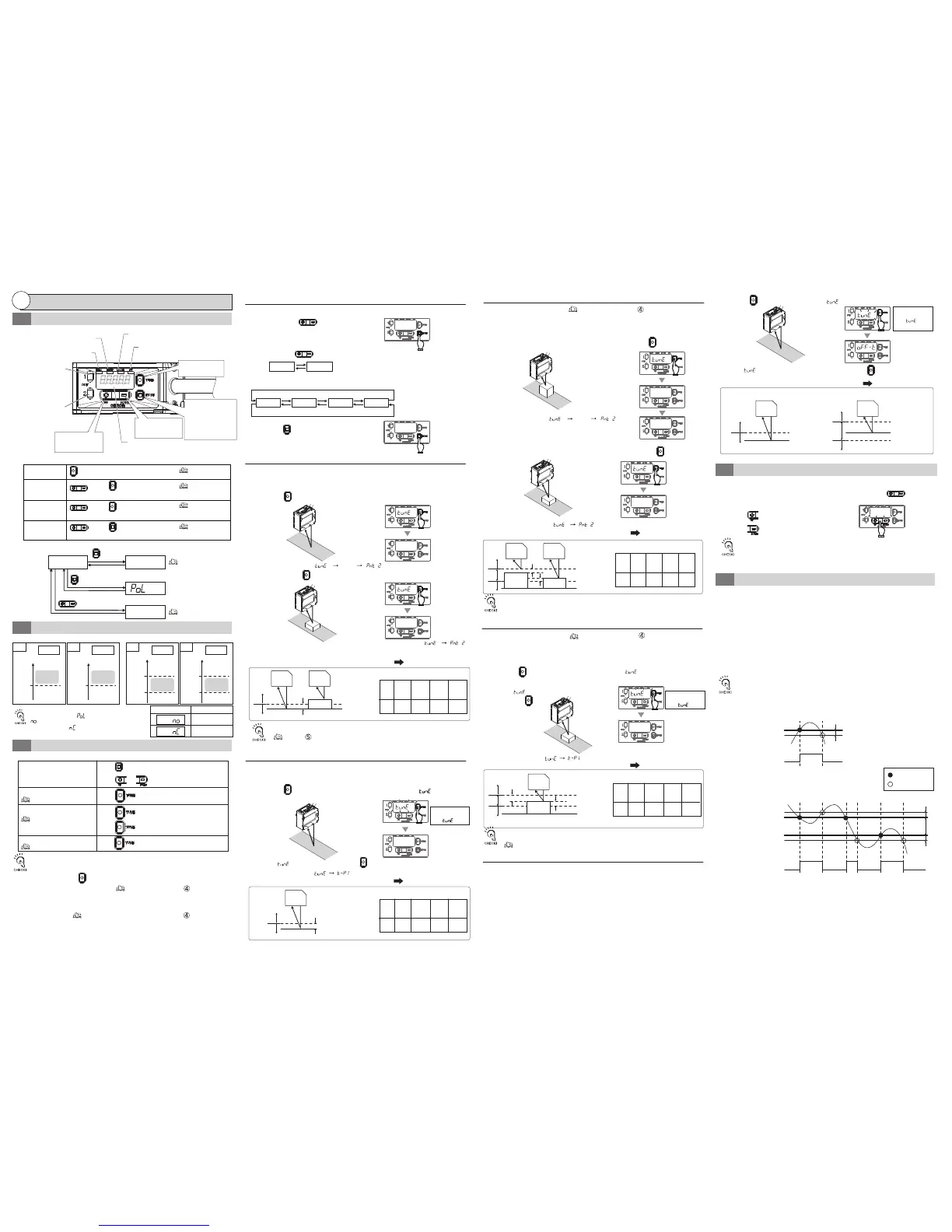

2-2

Setting and Display Overview

Output and Threshold Value

2-1

MODE

UP/DOWN

Hold for

min. 3 sec.

Less than 3 sec.

Menu Setting mode

Refer to "2-3 (1)".

CH Setting mode

Measurement mode

0.00

MODE

Less than 1 sec.

Threshold Setting mode

ch-1

No operation for min. 2 sec.

10.00

■

Switching to Individual Modes

■

Other Button Operation

Tuning

Zero reset setting

Zero reset cancel

Key lock setting/

cancel

button

button+button

simultaneouslyforlessthan3sec.

button+button

simultaneouslyformin.3sec.

button+button

simultaneouslyformin.3sec.

Refer to "2-4".

Refer to "2-3"

Refer to "

③

(2)"

Refer to "

③

(1)"

Refer to "

③

(1)"

<Area Output is OFF> <Area Output is ON>

Measured value

CH1 CH1

OUT1 OUT2

CH2 CH2

OFF

OFF

OFF

OFF

OFF

OFF

Threshold

1

Threshold

2

Threshold

1H

Threshold

1L

Threshold

2H

Threshold

2L

Measured value

Measured value Measured value

OUT1 OUT2

MODE

UP/DOWN

UP/DOWN

UP/DOWN

TUNE

TUNE

TUNE

ON ON

ON ON

• TUNE1 input (external input terminal) can also replace the button operations

for tuning to CH1.

Tuning can be performed for TUNE2 to CH2.

•

When performing tuning, threshold values are recorded in EEPROM (non-volatile

memory) in the sensor. The writing life of EEPROM is 100,000 times. Be careful of

writing life when performing measurement-by-measurement tuning.

• The allocation of button and external input terminals can be fixed by

changing the tuning type.

Refer to " 2.Tuning Type, Detailed Settings"

Refer to "2-3 (1)", "2-3 (4)"

Refer to "2-3 (2)", "2-3 (3)"

Refer to "2-3 (5)"

1-point tuning

2-point tuning

Tuning mode without workpiece

CH setting mode

TUNE

Press button for 3 to 5 seconds.

Press button once for the 1st point.

Press button once for the 2nd point.

Press button for 5 seconds.

■

Quick Reference for Tuning Operation (Perform tuning after selecting a CH)

(Near)

(Far)

. . . .

[ZERO]Zero reset indicator (Orange)

[ST]Smart tuning indicator (Blue)

OUT2 Output indicator

Orange)

OUT1 Output indicator

(Orange)

Turns ON when tuning is performed with the background

suppression function ON.

Turns ON in MENU setting mode.

[MENU]Menu Indicator (Orange)

[LD ON]Laser ON indicator (Green)

Turns ON when zero reset is set.

Turns ON when sensor is emitting laser.

Digital display

Displays the displacement volume in

Measurement mode and setting

item/setting value in other modes.

■

Nomenclature and Function

Turns ON when the value

exceeds Threshold 1 or within

the range of 1L to 1H.

Turns ON when the value exceeds

Threshold 2 or within the range

of 2L to 2H.

[TUNE]button

Used to perform tuning.

[MODE]button

Switches between

Measurement mode and MENU

setting mode by holding it for

3 seconds or longer. Switches

to CH Setting mode when it is

pressed less than 3 seconds.

[DOWN]button

Used to change a

threshold value or select

a setting item.

[UP]button

Used to change a

threshold value or select

a setting item.

Refer to " 5. Background suppression function, Detailed Settings"

88888

The display changes [ ] [ ] and 1-point area tuning is completed.

The measured value display returns.

Sensor

Threshold

H

D

D 0.13 0.4 2 9

Threshold

L

Sensor

Lower limit

workpiece

ON

OFF

OFF

The margin (D) for the upper/lower limit of

each model is as follows (fixed value):

Model

ZX1-

LD50

□

ZX1-

LD100

□

ZX1-

LD300

□

ZX1-

LD600

□

D

Background

(Reference surface)

Upper limit

workpiece

Unit (mm)

D

D

0.13 0.4 2 9

ON

OFF

OFF

D

ZX1-

LD50□

ZX1-

LD100□

ZX1-

LD300□

ZX1-

LD600□

Sensor

Workpiece

Threshold H

Threshold L

Background

(Reference

surface)

The margin (D) for the upper/lower limit of

each model is as follows (fixed value):

Model

Unit (mm)

The above figures represent the behaviors when

the output polarity [ ] is set to normally-open

[ ] (initial value). If the polarity is set to

normally-closed [ ], the ON/OFF polarities in

the figures are reversed.

Output polarity

Output at detection

ON

OFF

Press button to enter CH setting mode, and then

press or button to select a CH.

MODE

•

When setting the background suppression function to ON and performing tuning,

the measurement value and sensitivity level can be limited according to the sensitivity.

Use it when abnormal distance is detected due to diffuse reflection caused by surrounding walls, etc.

Sensor

Threshold

Reference surface

Sensor

Workpiece

ON

OFF

Without workpiece

0.2 0.7 3 15

D

ZX1-

LD50□□

ZX1-

LD100□□

ZX1-

LD300□□

ZX1-

LD600□□

The margin (D) for the Threshold of

each model is as follows (fixed value):

Model

Unit (mm)

D

Threshold

Reference surface

Without workpiece

Sensor

ON

OFF

0.2 0.7 3 15

D

ZX1-

LD50□□

ZX1-

LD100□□

ZX1-

LD300□□

ZX1-

LD600□□

The margin (D) for the Threshold of

each model is as follows (fixed value):

Model

Unit (mm)

D

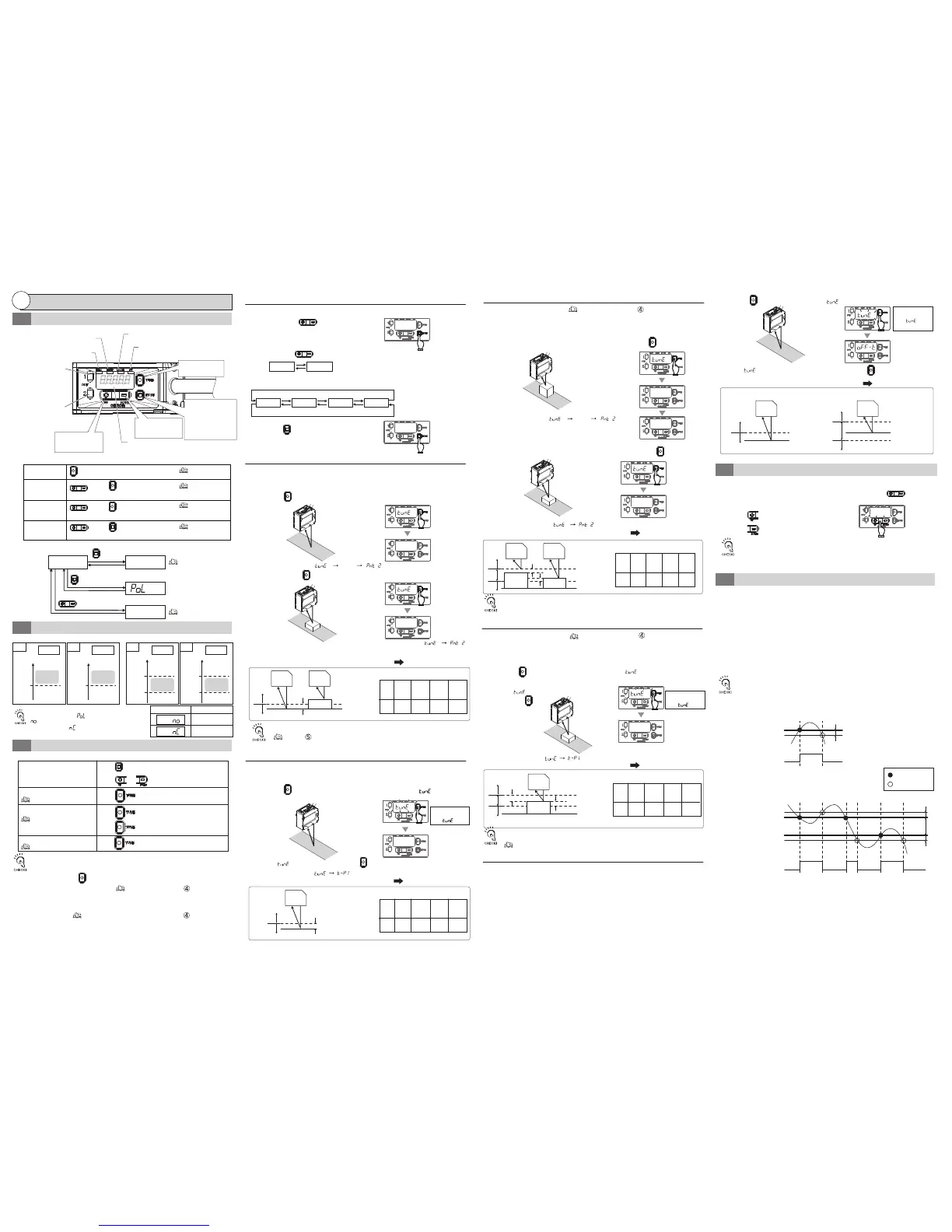

Fine Adjustment of Hysteresis Width

2-5

●

Hysteresis Width Setting

A minute step can be judged by adjusting the hysteresis width according to the

workpiece. However, note that the judgment output varies if lowering the hysteresis

width while the displacement value is varying due to moving workpiece or low

reection light intensity.

●

What is Hysteresis Width?

A point in which a judgment output turns from OFF to ON is called an operating

point, and a point in which a judgment output turns from ON to OFF is called a return

point. On this sensor, threshold means operating point, and a distance to the return

point can be set based on the hysteresis width.

Note that the direction where the hysteresis width is set for the threshold differs

depending on ON/OFF of the area output.

Threshold

HysteresisWidth

HysteresisWidth

Judgmentoutput

Judgmentoutput

AreaoutputisOFF

Measuredvalue

Measuredvalue

AreaoutputisON

Operatingpoint

Returnpoint

ON

OFF

ThresholdL

ON

OFF

ThresholdH

Loading...

Loading...