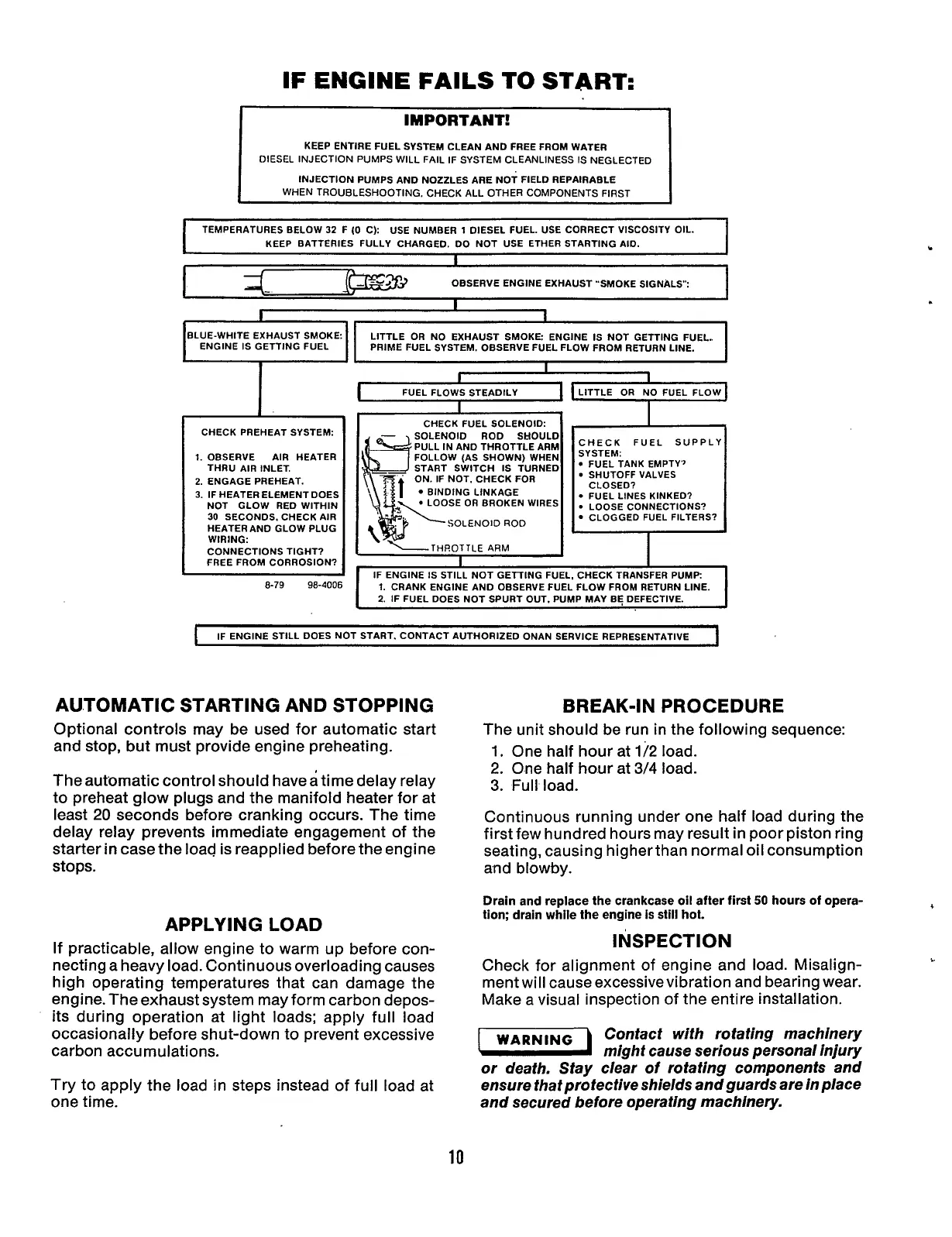

IF

ENGINE FAILS

TO

START:

KEEP ENTIRE FUEL SYSTEM CLEAN AND FREE FROM WATER

DIESEL INJECTION

PUMPS

WILL FAIL IF SYSTEM CLEANLINESS

IS

NEGLECTED

INJECTION PUMPS AND NOZZLES ARE NOT FIELD REPAIRABLE

BLUE-WHITE EXHAUST SMOKE:

ENGINE

IS

GETTING FUEL

LITTLE

OR

NO EXHAUST SMOKE ENGINE

IS

NOT GETTING FUEL.

PRIME FUEL SYSTEM. OBSERVE FUEL FLOW FROM RETURN LINE.

.

1

I

8-79

98-4006

I

1

I

FUEL FLOWS STEADILY LITTLE

OR

NO FUEL FLOW

I

IF ENGINE

IS

STILL NOT GElTlNG FUEL, CHECK TRANSFER PUMP

1.

CRANK ENGINE AND OBSERVE FUEL FLOW FROM RETURN LINE.

2.

IF FUEL DOES NOT SPURT OUT. PUMP MAY BE DEFECTIVE.

I

CHECK PREHEAT SYSTEM:

1.

OBSERVE AIR HEATER

THRU AIR INLET.

2.

ENGAGE PREHEAT.

3.

IF HEATER ELEMENT DOES

NOT GLOW RED WITHIN

30

SECONDS. CHECK AIR

HEATER AND GLOW PLUG

WIRING:

CONNECTIONS TIGHT?

FREE FROM CORROSION?

II

I

CHECK FUEL SOLENOID:

I

CLOGGED FUEL FILTERS?

ON. IF NOT. CHECK FOR

BINDING LINKAGE

SOLENOID

ROD

-THROTTLE

ARM

I

I

IF ENGINE STILL DOES NOT START. CONTACT AUTHORIZED ONAN SERVICE REPRESENTATIVE

AUTOMATIC STARTING AND STOPPING

Optional controls may be used for automatic start

and stop, but must provide engine preheating.

The automatic control should have

a

time delay relay

to preheat glow plugs and the manifold heater for at

least

20

seconds before cranking occurs. The time

delay relay prevents immediate engagement of the

starter in case the load is reapplied before the engine

stops.

APPLYING LOAD

If practicable, allow engine to warm up before con-

necting a heavy load. Continuous overloading causes

high operating temperatures that can damage the

engine. The exhaust system may form carbon depos-

its during operation at light loads; apply full load

occasionally before shut-down to prevent excessive

carbon accumulations.

Try to apply the load in steps instead of full load at

one time.

BREAK-IN PROCEDURE

The unit should be run in the following sequence:

1.

One half hour at

l/2

load.

2.

One half hour at

3/4

load.

3.

Full load.

Continuous running under one half load during the

first few hundred hours may result in poor piston ring

seating, causing higher than normal oil consumption

and blowby.

Drain and replace the crankcase oil after first

50

hours of opera-

tion; drain while the engine

is

still hot.

INSPECTION

Check for alignment of engine and load. Misalign-

ment will cause excessivevibration and bearing wear.

Make a visual inspection of the entire installation.

Contact with rotating machinery

might cause serious personal injury

or death. Stay clear of rotating components and

ensure that protective shields andguards are in place

and secured before operating machinery.

10

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...