2/4

PPE INSPECTION - Inspection procedure - Crampons (110416)

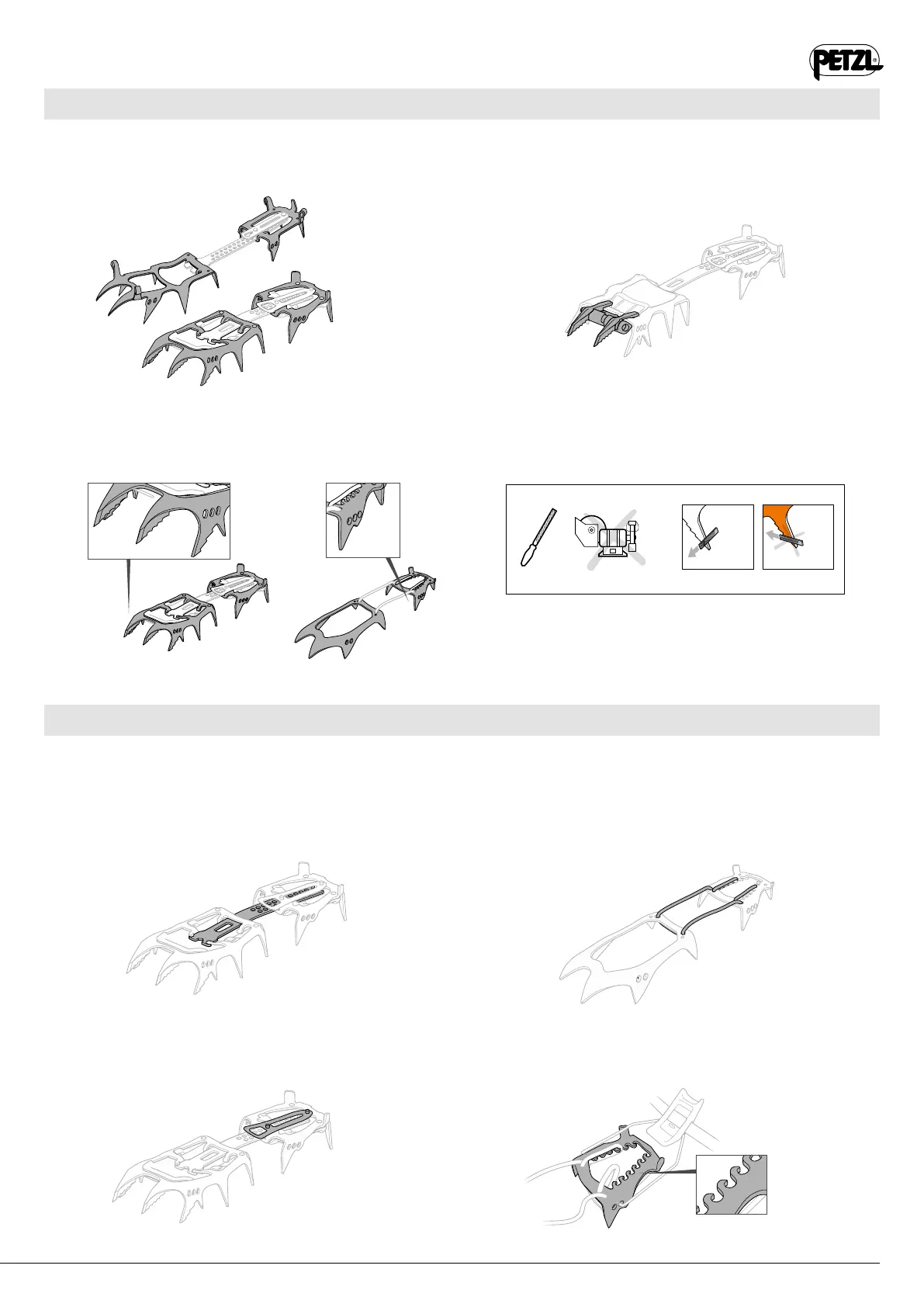

4. Inspecting the front and rear parts

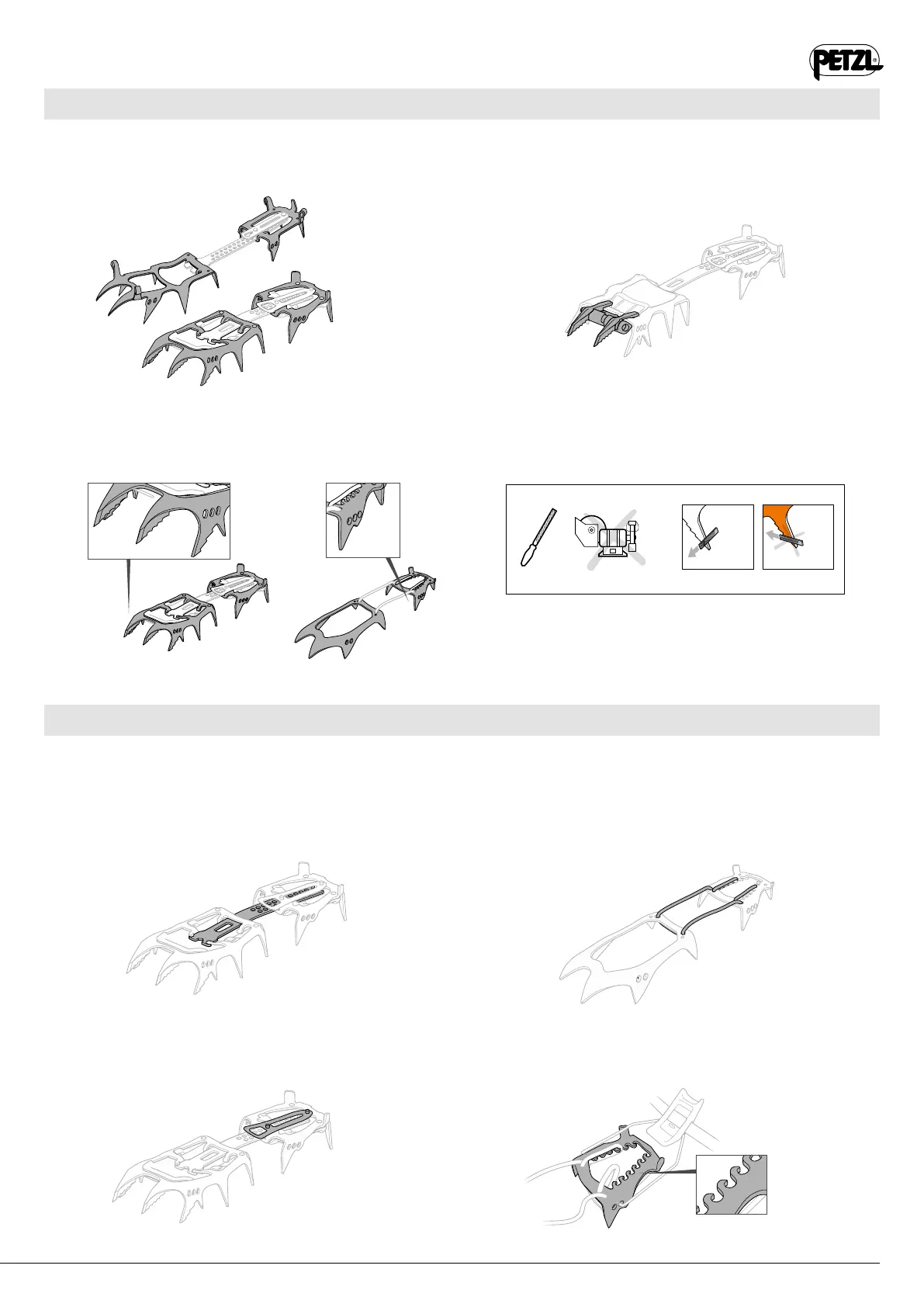

5. Checking the length adjustment system

• Check the condition of the points (wear, cracks, deformation,

corrosion...).

• Check the condition of the metal parts on the whole frame (wear,

cracks, deformation, corrosion...).

• On the LYNX crampon, check that the removable front points

are properly tightened and in good condition. See your crampons'

Instructions for Use for inspecting the installation of the points,

screws, nuts and spacers according to your chosen configuration

for the front points.

• If necessary, sharpen the points with a suitable tool.

• Check the condition of the linking bars (wear, cracks,

deformation, corrosion...) and their length. Move components to

inspect the hidden areas.

If necessary, replace the bars with new spare parts.

• Check the condition of the adjustment cords (wear, fraying,

condition of the stitching). Loosen the cord at all contact points on

the crampon to inspect hidden wear zones.

If necessary, replace the cords with new spare parts.

• Check the condition of the adjustment tabs (wear, cracks,

deformation, corrosion...).

• Check the condition of the adjustment hooks on the rear part

of the crampon (wear, cracks, deformation, sharp/rough edges,

corrosion...).

Loading...

Loading...