3 4

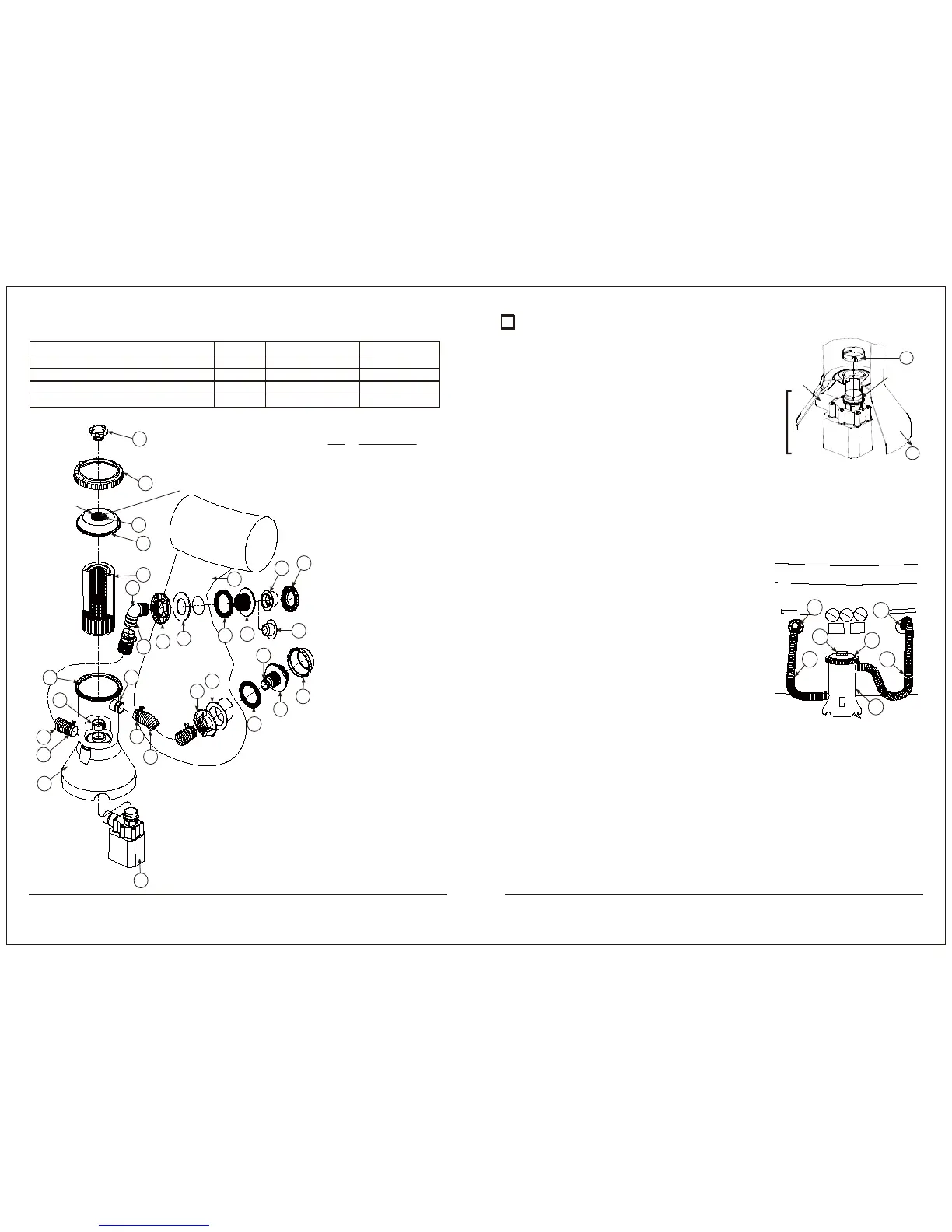

FIG. 1

• Risk of electrical shock, connect only to a grounding type receptacle

protected by a ground fault circuit interrupter, (GFCI). Contact a

qualified electrician if you cannot verify that the receptacle is

protected by a GFCI.

NOTE - The Power Filter will be in four sections: a pump; filter assembly; hardware bag; and suction / return hoses.

A. First, remove the Seal Top Retainer (10), Seal Top (9), and Filter Cartridge (15) from the assembled Filter Case.

Lubricate the pump O-ring with petroleum jelly. Hold the filter case (8) securely, and insert motor pump so that

the outlet on the volute housing extends out of the opening in the side of the filter case. Insert the motor pump

until the two ribs on the inlet of the volute housing protrude through the bottom of the filter case. Reach down

inside the filter case and place the Pump Retaining Nut (7) over the top of the volute housing inlet. Twist the Nut

(7) clockwise until it is snug. See Fig. 2.

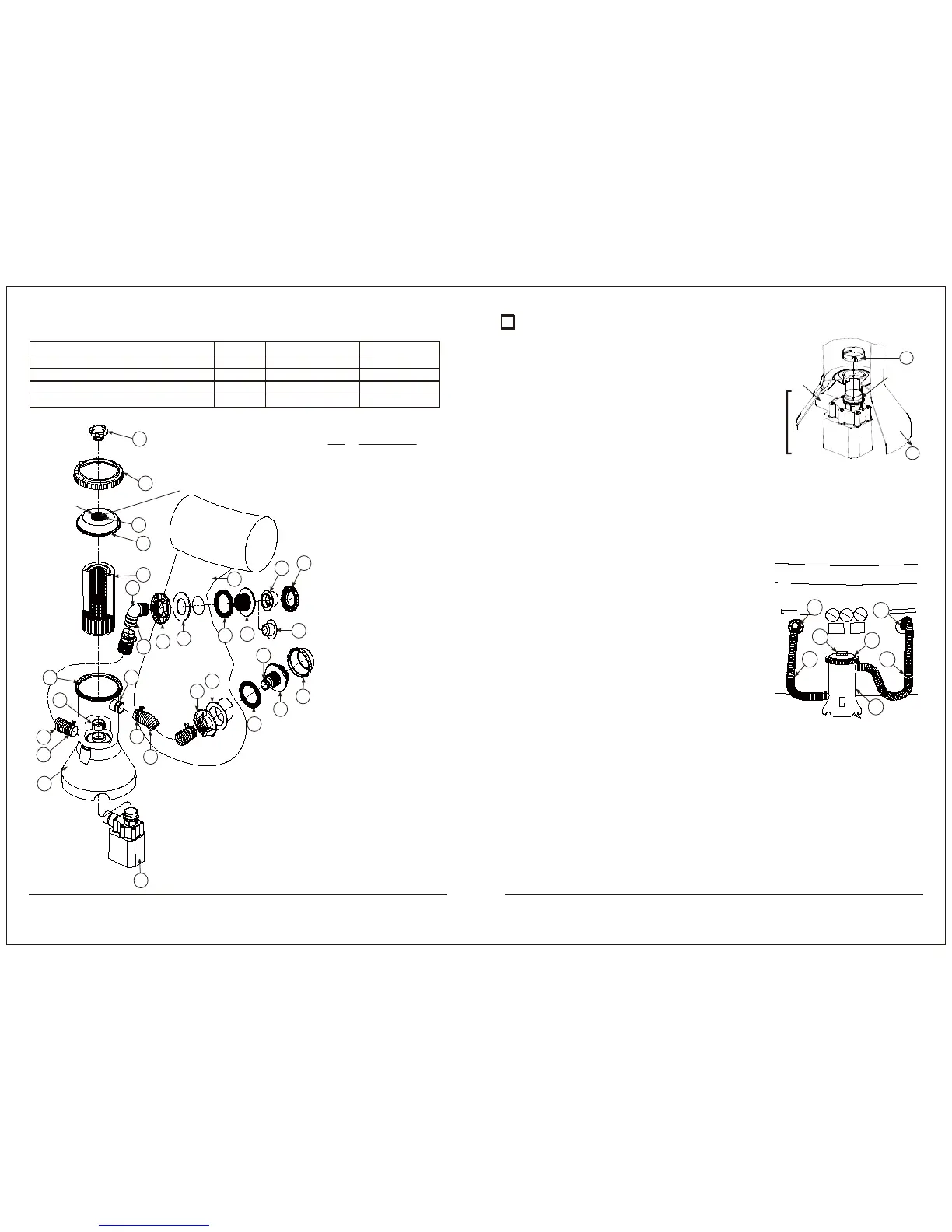

B. Get the Suction and Return Hoses (12, 13), and remove two Hose

Clamps (14), from the hardware bag. Loosen the hose clamps and

slide them over one end of each hose. Lubricate O-rings (24) on the

Filter Case (8) and Volute Housing liberally with petroleum jelly.

Install one hose on the filter case suction inlet at the top, and one

hose on the filter case return outlet at the base. Tighten both of the

Hose Clamps (14).

C. Locate the Return Fitting assembly parts (21, 25-31). Lubricate the

(black) RF Gasket (26) liberally with petroleum jelly and install it over

the threads on the Return Fitting (25). Insert the Return Fitting (25)

with the RF Gasket (26) through the pool return fitting hole in the

wall from the inside of the pool, see Fig. 3 for correct location. Place

the (white) RF Thrust Washer (27) over the Return Fitting and then

thread the RF Nut (28) onto the fitting until it is hand tight. DO NOT

over tighten the RF Nut or wrinkle the pool wall around the RF Thrust

Washer (27) or the RF Gasket (26). Plug the pool’s Return Fitting (25) with the RF Plug (21) from the inside of the

pool. Set the RF Diverter Fitting (30) and RF Locking Ring (31) aside for later installation. Now locate the Pool

Suction Fitting assembly parts (16-20). Lubricate the (black) SF Gasket (17) liberally with petroleum jelly and

install it over the threads on the Suction Fitting (16). Insert the Suction Fitting (16) with SF Gasket (17) through

the pool suction fitting hole in the wall from the inside of the pool. Place the (white) SF Thrust Washer (18) over

the Suction Fitting and then thread the SF Nut (19) onto the fitting until it is hand tight. DO NOT over tighten

the SF Nut or wrinkle the pool wall around the SF Thrust Washer (18) or the SF Gasket (17). Cap the pool’s

Suction Fitting (16) with the SF Water Cap (20). Only hand tighten the Water Cap (20). Start filling pool.

D. After the pool is filled, position the Filter Assembly between the two fittings on the side of the pool, about 6

inches out from the base. The suction hose (12), coming from the top of the filter case should be facing the right,

and the return hose (13) coming from the pump, on the lower side of the case, should be facing the left; see Fig.3.

FIG. 3

POOL

RETURN

FITTING

POOL

SUCTION

FITTING

14

14

11

13 12

9

8

Should you encounter any problems, contact the Customer Service at (888) 919-0070.

Extended operating days and hours during peak season requirements.

Should you encounter any problems, contact the Customer Service at (888) 919-0070.

Extended operating days and hours during peak season requirements.

4. The RP Type pump/filter systems are manufactured by Polygroup and ETL control number 4000608 - double

insulated and grounded - 115 V.A.C. - 60 Hz. (ALL Units must have a minimum of 105 V.A.C. to start and run

properly.)

RP600 Filter System with F600C Pump

RP800 Filter System with F700C Pump

RP1000 Filter System with F1000C Pump

RP1000 Filter System with F1500C Pump

RP2000 Filter System with F2000C Pump

46 watts

57 watts

80 watts

120 watts

210 watts

0.8 amps

1.1 amps

2.2 amps

2.2 amps

2.2 amps

580 G.P.H.

780 G.P.H.

1075 G.P.H.

1500 G.P.H.

2000 G.P.H.

THE FILTER CARTRIDGE (15) WILL HOLD 1”

DIAMETER CHLORINE TABLETS. CHECK

YOUR CHLORINE LEVELS TO DETERMINE

THE PROPER NUMBER OF TABLETS TO ADD.

LIBERALLY

LUBRICATE

THE O-RINGS

(17,22,23,24 &26)

WITH SOME

PETROLEUM

JELLY

PATENTED

FILTER

CARTRIDGE

SYSTEM #7,005,062

KEY DESCRIPTION

1-6 MOTOR PUMP

7 PUMP RETAINING NUT

8 FILTER CASE

9 SEAL TOP

10 SEAL TOP RETAINER

11 VENT SCREW

12 SUCTION HOSE

13 RETURN HOSE

14 HOSE CLAMPS

15 FILTER CARTRIDGE

16 SUCTION FITTING (SF)

17 SF GASKET (Black)

18 SF THRUST WASHER (White)

19 SF NUT

20 SF WATER CAP (Use for service only)

21 RF PLUG (Use for service only)

22 O-RING (On Filter Case)

23 O-RING (On Vent Screw)

24 O-RING (On Hose Connections)

25 RETURN FITTING (RF)

26 RF GASKET (Black)

27 RF THRUST WASHER (White)

28 RF NUT

29 RF ELBOW 90°

30 RF DIVERTER FITTING

31 RF LOCKING RING

32 POOL WALL

11

10

23

9

15

29

24

22

7

13

14

4 Ea.

4 Ea.

8

12

14

24

19

18

16

20

17

1-6

28

27

26

25

24

21

30

31

32

]Volute Housing

Pump System Wattage Amperage Flow Rate

*GPH - Gallons Per Hour

FIG. 2

7

8

Volute

Housing

Outlet

Motor Pump

Volute

Housing

Inlet

1 POWER FILTER INSTALLATION: (Reference Page 3, Fig. 1)

WARNING - EXTREMELY IMPORTANT!

• Receptacle must be at least 10 feet away from pool.

• Filter system can be used as many hours as desired.

• Do not use an extension cord to connect unit to electric

supply; provide a properly located outlet.

• Do not bury the cord.

Loading...

Loading...