THE PRESENT MANUAL BELONGS TO - Schenker Italia - ALL RIGHTS RESERVED

24

6.6.1 Necessary Equipment

The following equipment is necessary to perform the shutdown operation:

1. The provided plastic tank filled with at least 15 litres of fresh water;

2. 2 hoses (provided) to be connected to:

- inlet of the pump (red flag hose)

- discharge of the watermaker

3. A bottle of powder SCHENKER CLEANING 1 (SC1). The solution must be prepared following the

instruction indicated on the bottle label, and using unchlorinated water (for instance water produced

by the system can be an option).

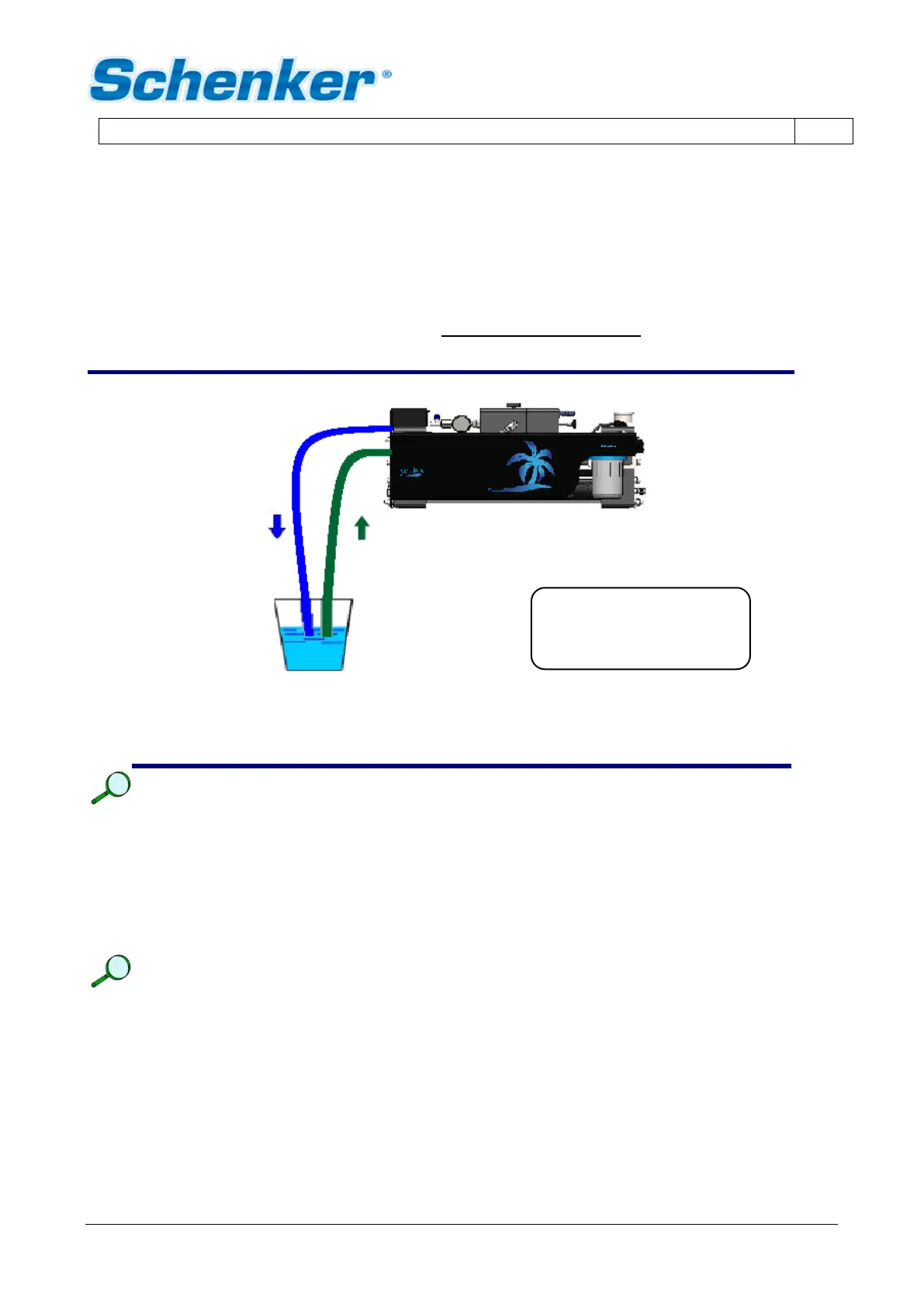

HYDRAULIC SCHEME FOR SHUTDOWN PROCEDURE

FIG. 6-1

NOTE

The available products for the shutdown procedure are the followings:

1) SCHENKER CLEANING 1 (SC1 – Acid product) to remove the inorganic components and preserve

the watermaker during winter break.

2) SCHENKER CLEANING 2 (SC2 – Alkaline product) to remove the organic components (mould and

bacteria) when already deposited; in this case, the system and/or the water produce a “bad eggs”

smell. Allow a period of 20 mins for both acid & alkaline cleaning.

It is important that the depressurizing valve is partially open when this procedure is carried out.

NOTE

Normally only SC1 is required, but in case of strong bad smell (organic contamination) it is

recommended to use SC2 as well.

The sequence in this case will be SC2 first, then a flushing of the unit with fresh water, and finally the

SC1. Leave the product in the system to winterize the unit.

It is advisable to replace the filters after performed the cleaning procedure with new ones.

If the unit will not be used for a long period of time (for example before winter) the filters can also be

removed.

Loading...

Loading...