Connecting

Standard machines_Operating_Instructions_Compact

56100000002001 EN, 01/2010

7

●

.

ct coupling.

ing surfaces must be clean

ut for any damage to paint; this must be rectified immediately and

sonances with the rotating frequency and

double line frequency; these must be prevented.

for unusual noises when turning the rotor manually.

e direction of rotation with the machine decoupled.

Flatness

Alignment and fastening

When aligning and fastening the machine, please bear the following in mind:

The machine must be level.

● Feet and flanges must be fastened securely

● Alignment must be precise in the case of dire

● Fasten

● Look o

correctly.

● Look out for traces of anti-corrosion protection agents; these must be removed

using mineral turpentine.

● Look out for installation-related re

● Listen

● Check th

● Avoid using rigid coupling measures.

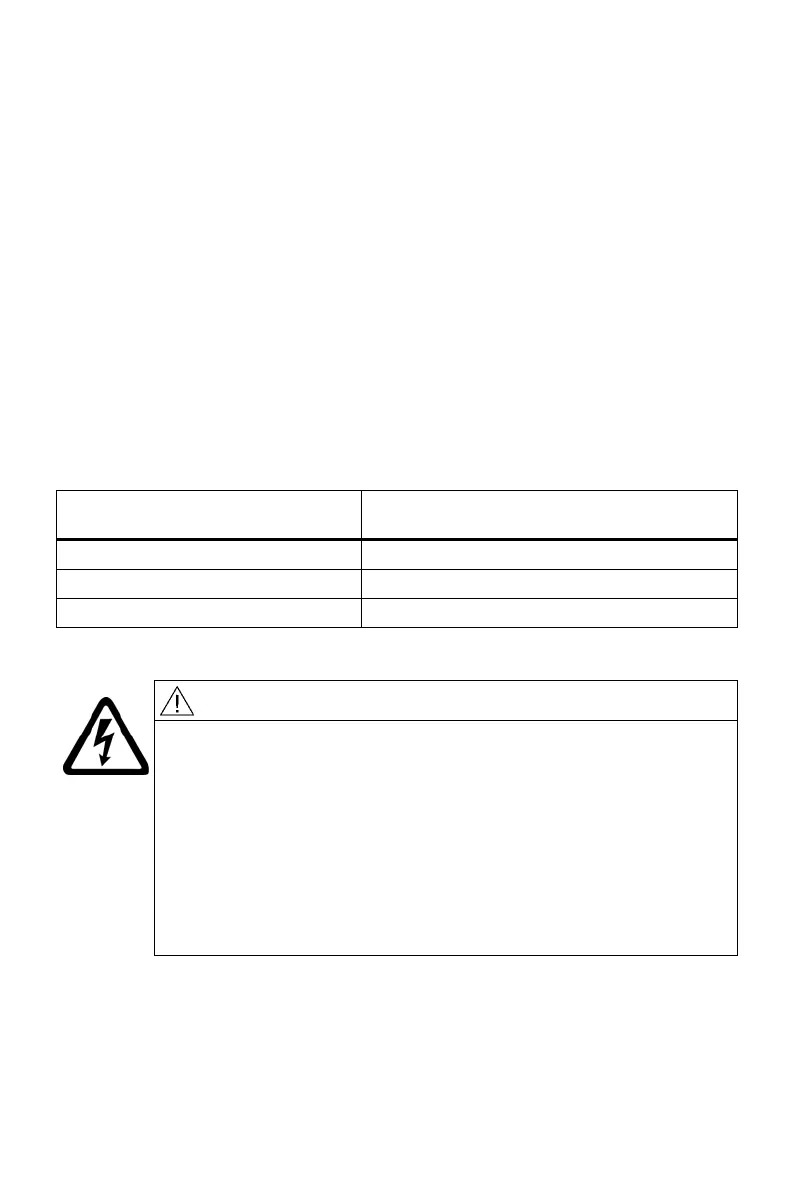

Flatness of the supporting surfaces for conventional motors

Frame size

(FS) mm

≤ 132 0.10

160 0.15

≥ 180 0.20

Connecting

WARNING

Any

pers

work on the stationary machine must be performed by qualified

onnel, with the machine isolated from the supply and secured so

t it cannot be switched back on again. This also applies to auxiliary

rom the

Before starting work, make sure that a protective conductor is securely

connected.

tha

circuits (e.g. anti-condensation heater). Check that the equipment is

isolated from the supply.

If the incoming power supply system displays any deviations f

rated values for voltage, frequency, curve form, or symmetry, such

deviations will exacerbate the increase in temperature and influence

electromagnetic compatibility.

Loading...

Loading...