Normal operation

Measure the normal operating temperature T

operation

at the installation site in °C. Set the values

for shutdown and warning according to the operating temperature T

operation

. The set values

depend on the design of the insulation system or the temperature class of the machine. The

data can be found on the rating plate.

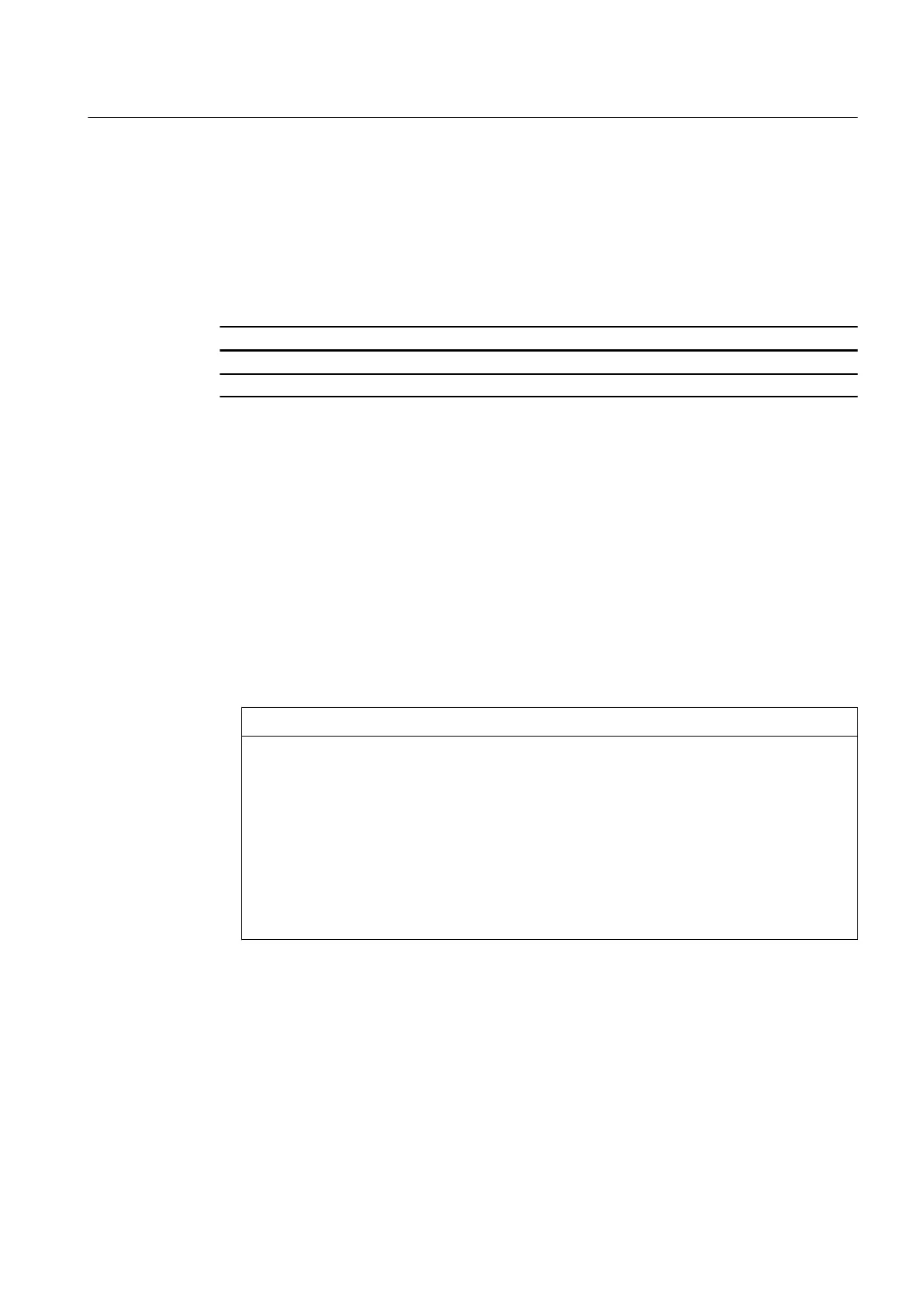

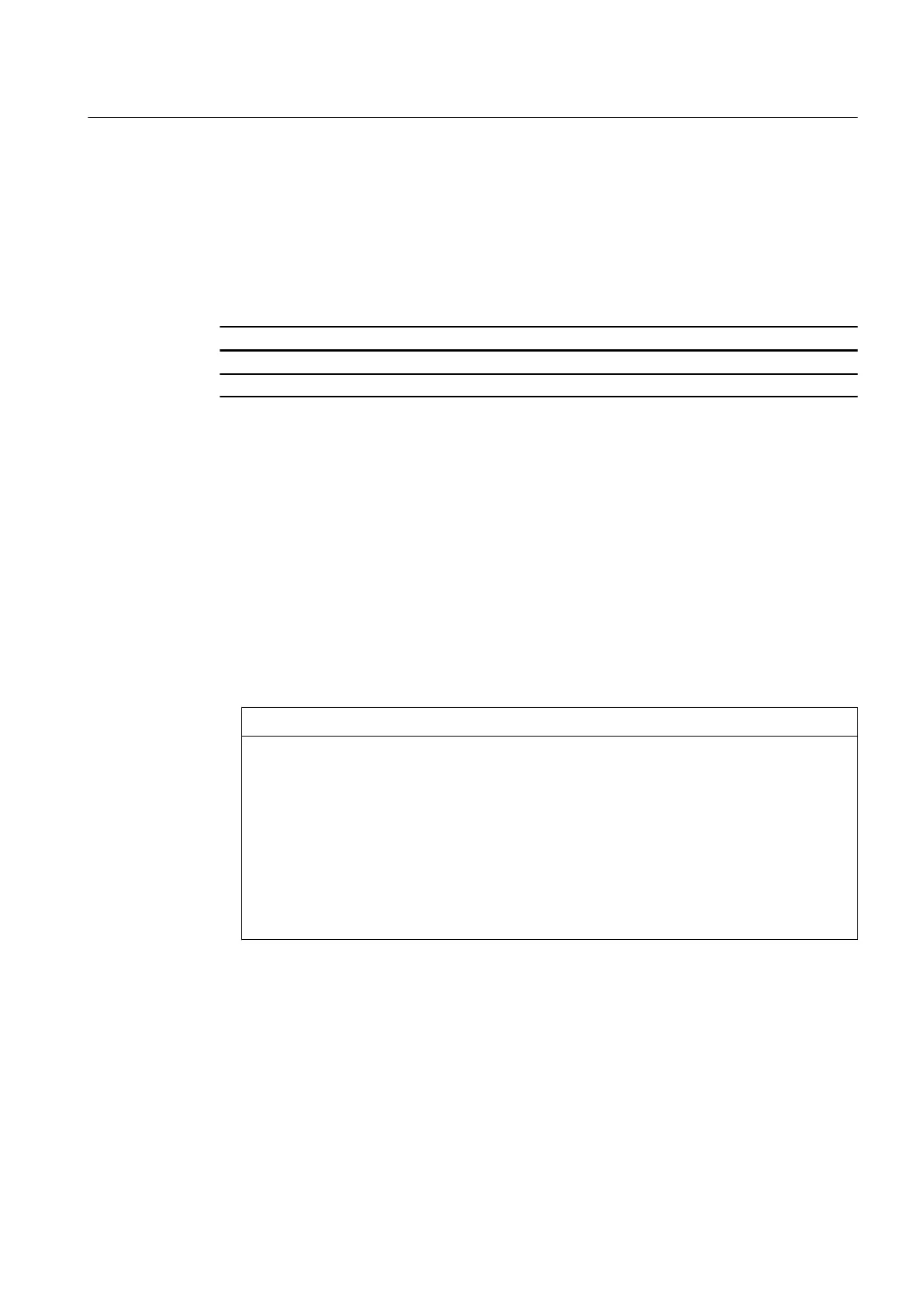

Table 7-4 Set values for monitoring the winding temperatures in normal operation

Set value Insulation class 155(F) Insulation class 180(H)

Warning T

op

+ 10 K ≤ 145 °C T

op

+ 10 K ≤ 170 °C

Shutdown T

op

+ 15 K ≤ 155 °C T

op

+ 15 K ≤ 180 °C

7.6 Test run

After installation or inspection, carry out a test run:

1. Start up the machine without a load. To do this, close the circuit breaker and do not switch

off prematurely. Check whether it is running smoothly.

Switching the machine off again while it is starting up and still running at slow speed should

be kept to a bare minimum, for example for checking the direction of rotation or for checking

in general.

Allow the machine to run down before switching it on again.

2. If the machine is running smoothly and evenly, switch on the cooling equipment. Continue

to observe the machine for a while in no-load operation.

3. If it runs perfectly, connect a load.

NOTICE

Thermal overload of motors connected directly to the line supply

In addition to the load torque, the ramp-up (accelerating) time is essentially influenced by

the moment of inertia to be accelerated. While ramping up when connected to the line

supply, the inrush (starting) current is a multiple of the rated current. This can result in

thermal overload. This can damage the motor.

As a consequence, when ramping up, observe the following:

● Monitor the ramp-up time and number of consecutive starts.

● Comply with the limit values and/or ramp-up conditions specified in the catalog or the

order documentation.

Start-up

7.6 Test run

SIMOTICS TN Series N-compact 1LA8

Operating Instructions 05/2016 85

Loading...

Loading...