Edition Manual Chapter Page

2014-09-09 Workshop Manual, GGP Park 2 Chassis and body 3

2.2 Lubrication chassis

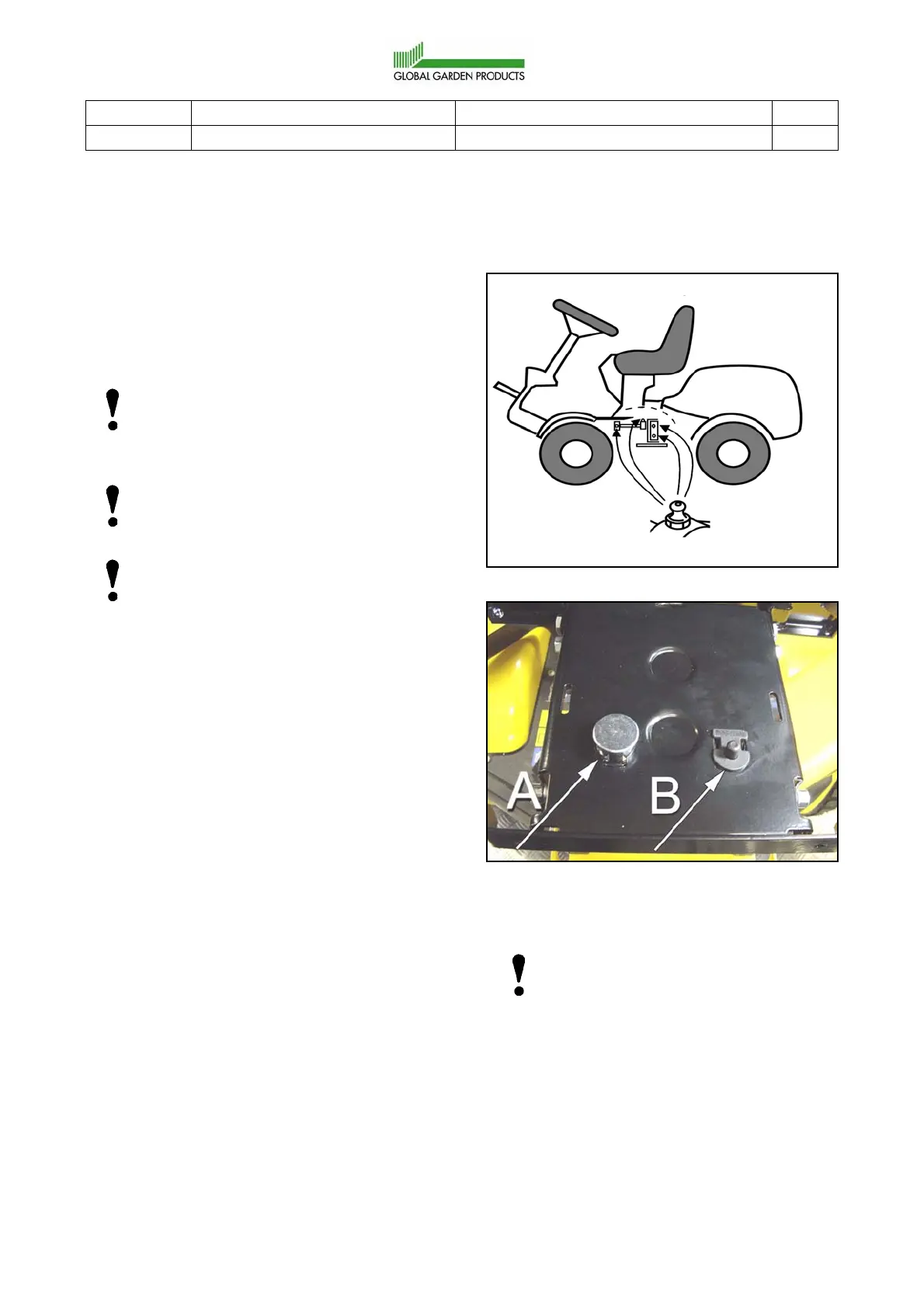

The bearing for the articulation must be

lubricated in accordance with the service

schedule. Other moving parts are lubricated

once per season, although at least every 50

operating hours.

Note!

Lubrication is equally important for a

machine that is only used for a few hours

per year.

Note!

The lubricant provides not only

protection from wear but also from rust.

Note!

The machine should always be

lubricated before prolonged storage.

The bearing for the articulation has four grease

nipples which must be lubricated with universal

grease.

The steering chain must be lubricated with

chain spray two or three times per season.

If the chains are heavily fouled: dismantle the

chains and wash them.

Refit and lubricate them.

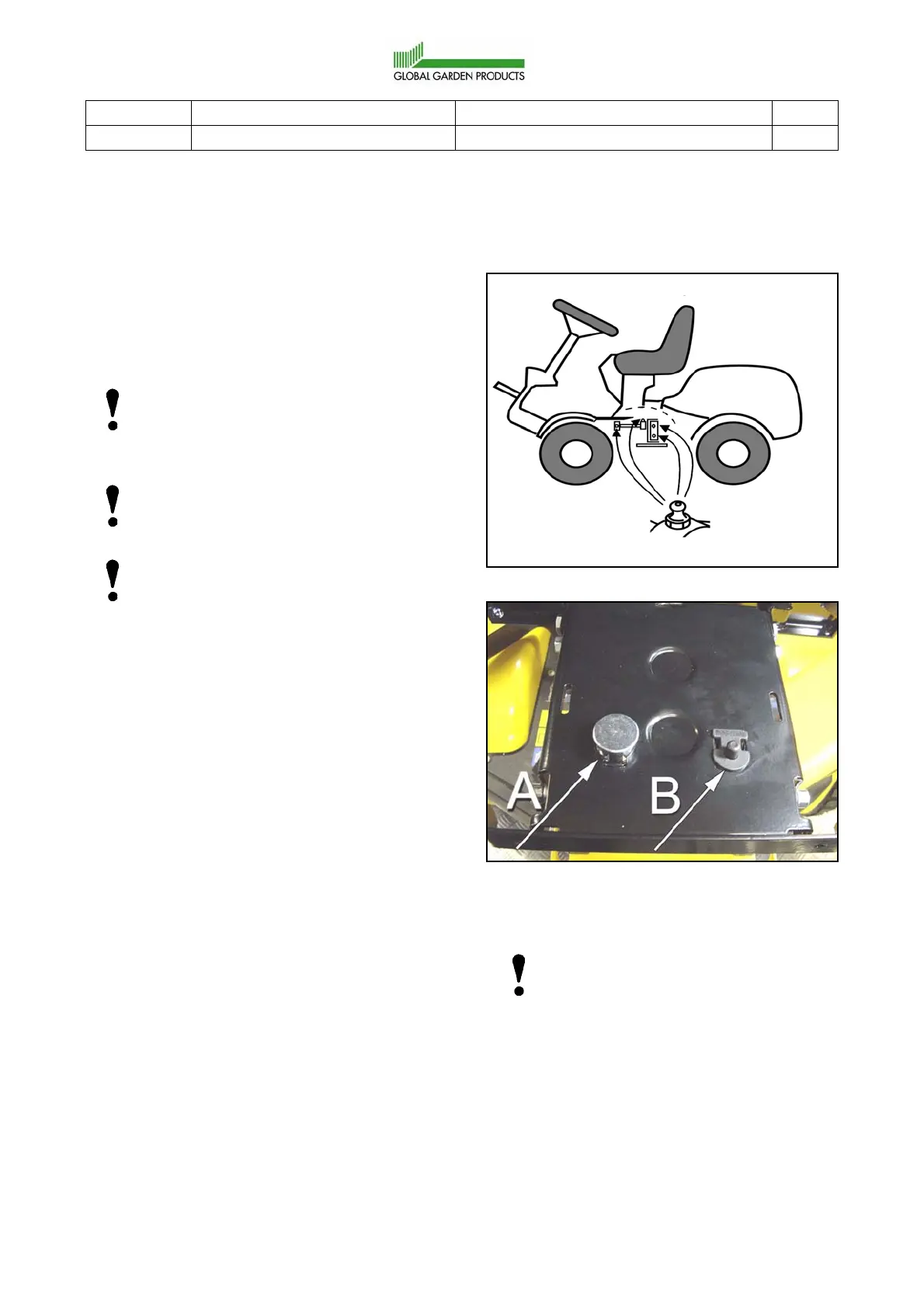

The pressure pin (A) in the seat suspension

must be lubricated to avoid problems with the

safety circuit.

Plastic bearings, e.g. the brake pedal bearing,

hydrogear pedal bearing and steering-column

bearing, must be lubricated with grease or

lubricating spray.

Drop a little engine oil or lubricating spray in the

ends of the control wires two or three times a

year.

Note!

Wires on machines used in

freezing conditions should not be

lubricated with engine oil since

this can lead to the control cables

seizing in the cold.

The wires on such machines

should be lubricated with a

fluent, strongly penetrating

lubricant, e.g. 5-56 or WD40.

Loading...

Loading...