HT 100, HT 101, HT 130, HT 131

English

30

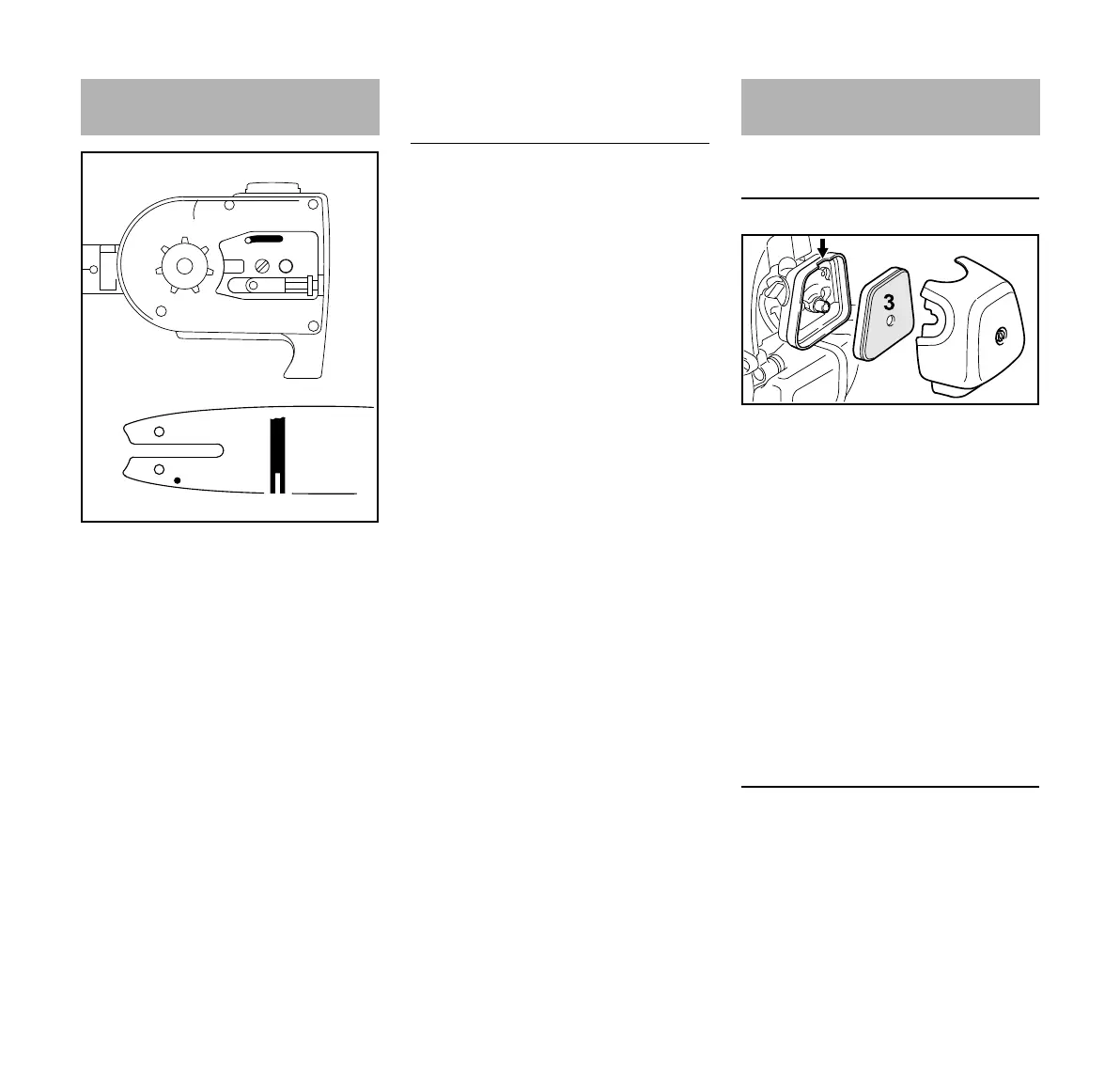

N Turn the bar over – every time you

sharpen the chain and every time

you replace the chain – this helps

avoid one-sided wear, especially at

the nose and underside of the bar.

N Regularly clean the oil inlet hole (1),

the oilway (2) and the bar

groove (3).

N Measure the groove depth – with the

scale on the filing gauge (special

accessory) – in the area used most

for cutting.

If groove depth is less than specified:

N Replace the guide bar.

The drive link tangs will otherwise

scrape along the bottom of the groove –

the cutters and tie straps will not ride on

the bar rails.

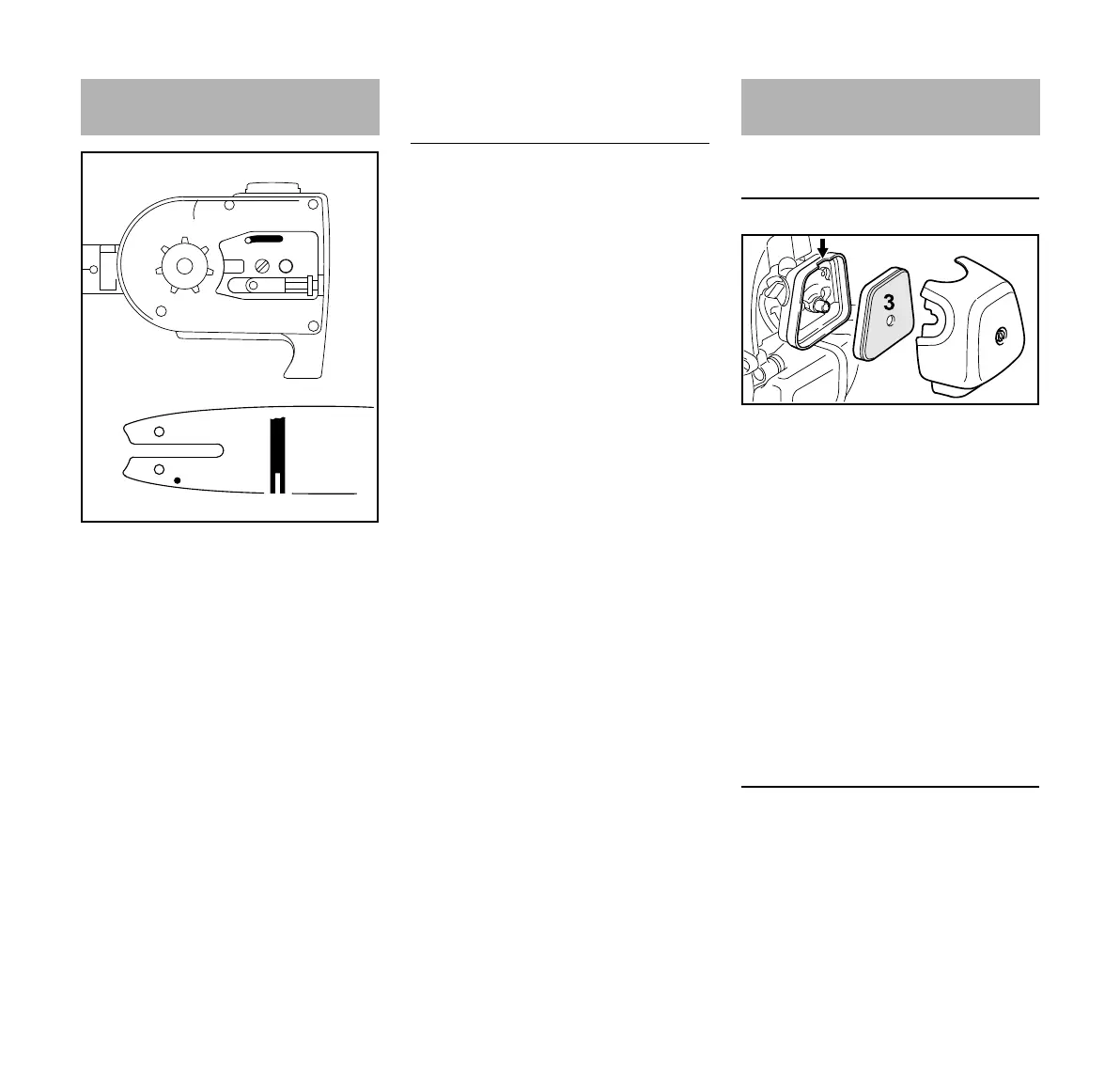

If there is a noticeable loss of engine

power

N Turn the choke knob to g

N Take out the screw (1) and remove

the filter cover (2).

N Clean away loose dirt from around

the filter.

N Grip the filter element (3) at the

cutout (arrow) in the filter

housing (4) and remove it.

N Fit a new filter element. As a

temporary measure you can knock it

out on the palm of your hand or blow

it out with compressed air. Do not

wash.

N Replace damaged parts.

Installing the filter

N Install the filter element in the filter

housing and fit the cover.

N Insert the screw and tighten it down

firmly.

Taking Care of the Guide Bar

Chain type Chain pitch Minimum

groove

depth

Picco 3/8" P 0.20"

(5.0 mm)

Rapid 1/4" 0.16"

(4.0 mm)

Picco 1/4" P 0.16"

(4.0 mm)

Cleaning the Air Filter

Loading...

Loading...