Suzuki

DT2

WBRICATION

The

power

head

is

lubricated

by o

il

mixed

with

the

fueL Fuel:o

il

ratio

should be

30:1 during

br

ea

k-in

of

a

new

or

rebuilt engine. Fuel:oil ratio for

nor

-

mal service

is

50: I

on

models

prior

to

1987

and

100:1

on

1987

and

later

models. Recommended oil is Suzuki O

ut

-

board Motor

Oil

or

a good quality

NMMA

certified

TC-W

oiL

When using any oth-

er

type

of

two-stroke engine oil, fuel:o

il

ratios should

be

20: I

during

break

-in

and

30:1 for

normal

service

. Manufac-

turer

recommends

regular

or

unleaded

automotive ga';oline having

an

85-95 oc-

tane

rating. Gasoline

and

oil

should

be

thoroughly mixed.

The lower

unit

gears

and

bearings

are

lubricated with SAE 90 hypoid outboard

gear

oil. Lower

unit

capacity

on

models

priorto

1987

is

approximately 40 mL

(1.3

oz.). Oil

capacity

on

lat

er

models

is ap-

proximately

70

mL (2.4 oz.) on

short

drive

shaft

models

and

120 mL

(4

.1 oz.)

on

long drive shaft. models. On

early

models (prior

to

1987). lay

motor

on

side

to

fill

with

oil.

Later

models

are

equipped

with

a

vent

/oil level

check

plug on side

of

gearcase. Reinstall plug

securely using a

new

gasket if necessary

to

ensure

a

water

tight

seal.

FUEL SYSTEM

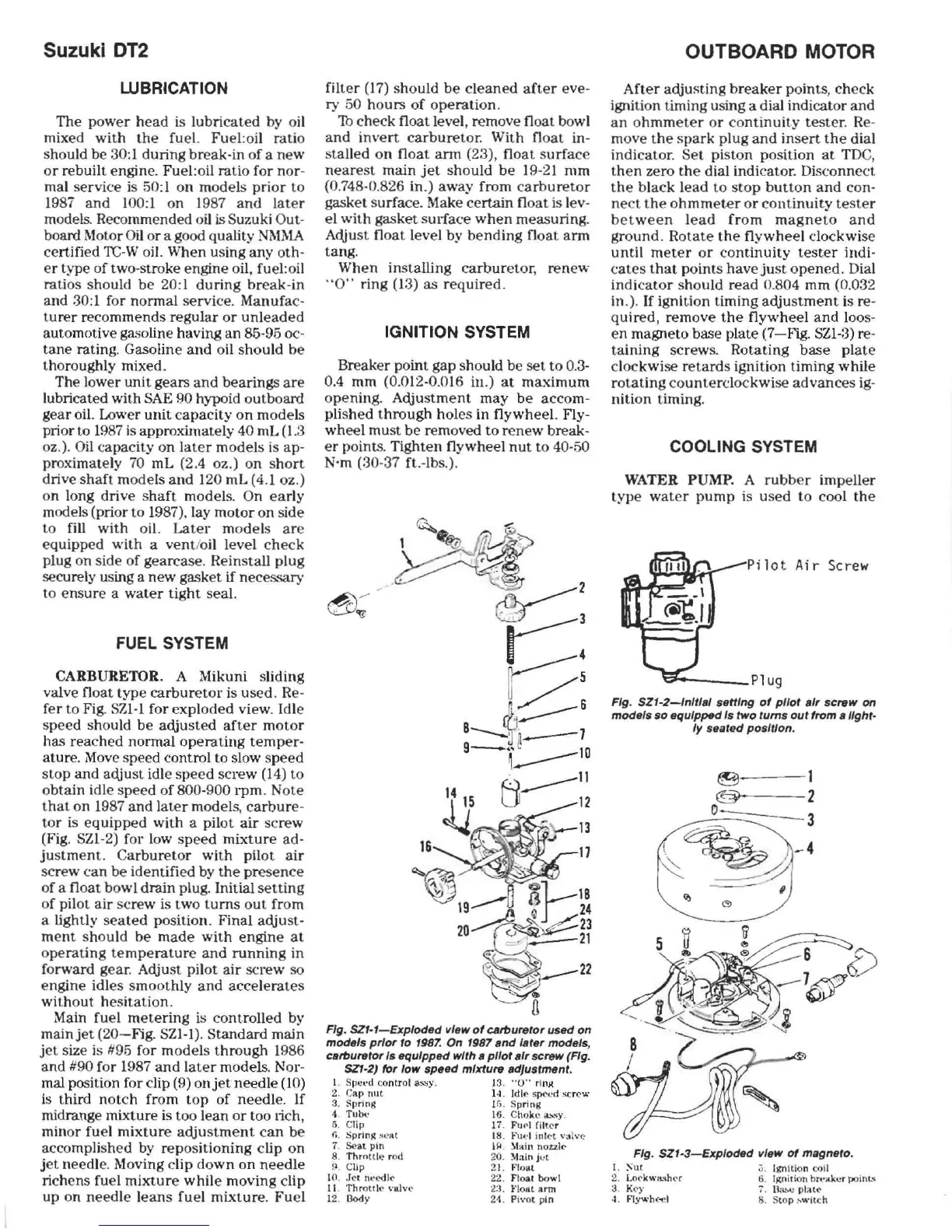

CARBURETOR. A Mikuni sliding

valve float

type

carburetor

is

used

. Re-

fer to Fig.

S21-1

for

exploded

view. Idle

speed

should

be

adjusted

after

motor

has

reached

normal

operating

temper-

ature. Move speed control to slow

speed

stop

and

adjust idle

speed

screw

(14) to

obtain

idle

speed

of

800-900

rpm.

Note

that

on

1987

and

later

models,

carbure

-

tor

is

equipped

with a pilot

air

screw

(Fig.

SZI-2) for low

speed

mixture

ad-

ju

s

tment.

Carburetor

with

pilot

air

screw

can

be

identified by

the

presence

of

a float bowl drain plug. Initial

setting

of pilot

air

scre

w

is

two

turns

out

from

a lightly

seated

position. Final adjust-

ment

should

be

made

with

engine

at

ope

rating

temperature

and

running

in

forward

gear

. Adjust pilot

air

screw so

engine

idles

smoothly

and

accelerates

without

hesitation.

Main fuel

metering

is controlled by

main

jet

(20-Fig.

SZI-I).

Standard

main

jet

size is

1195

for

models

through

1986

and

1190

for 1987

and

later

models. Nor-

mal position for clip (9)

onjet

needle

(10)

is

third

notch

from

top

of

needle. If

midrange mixture

is

too lean

or

too lich,

minor fuel

mixture

adjustment

can

be

accomplished by

repositioning

clip

on

jet

needle. Moving clip

down

on

needle

richens fuel

mixture

while

moving clip

up

on

needle

leans

fuel

mixture.

Fuel

filter

(17)

should

be

cleaned

after

eve-

ry

50

hours

of

operation.

Th

check float level, remove float bowl

and

invert

carburetor.

With float in-

stalled

on

float

ann

(23), float

surface

nearest

main

jet

should

be

19-21

mm

(0.748-0.826 in.) away from

carburetor

gasket surface. Make

certain

flo

at

is

lev-

el

with

gasket

surface

when

measuring.

Adjust float level by

bending

float

arm

tang.

When installing

carburetor,

renew

"0"

ring (13)

as

required.

IGNITION SYSTEM

Breaker point gap should

be

set

to

0.3-

0.4 mm (0.012-0.016 in.)

at

maximum

opening.

Adjustment

may

be

accom-

plished

through

holes in flywheel. Fly-

wheel

must

be

removed

to

renew

break-

er

ャIッゥョエNセ

N@

Tighten flywheel

nut

to

40-50

N'm (30-37

fUbs

.).

Fig.

SZI-I-Exploded

view

of

c."'urelo,

used on

models

p,'o,

10

1987.

On

1987

snd

I.

Ie'

models,

CB"'urero, Is equipped wlrh • pI/or

.,,

screw (Fig.

SZ1-2)

fo,

'ow

speed

mixture sd/usrmen/.

1.

sーセエNNᄋ、@

co

ntr

ol

a.:;::;y.

13

"0"

イエョセ@

2.

CIlP

nut

14. Idle sp

eed

scrc

.....

3. Spring

tG

. Spring

1. Tube: 16.

c

ィッォ セ@

a..-..,

..

y .

5. C

lip

17

.

FUf'J

(iller

fl

.

SprlnR

!l

C!l(

18

.

l-'uI

.'1

illiN

\.'

;]

\ve

1.

セ。エ@

pin

Qセ

N@

:\11Iin

nO:t:l

lc

8.

Thr

ottle

rod 20.

:\1.'110

j

et

f)

Clip 21.

Float

10 .

.TN

n

..

'OOle

22. Float

bowl

11.

Throttle

valve

23.

FIOfll

ann

12. Dody 2

-1

.

Pi\'ot

pin

OUTBOARD

MOTOR

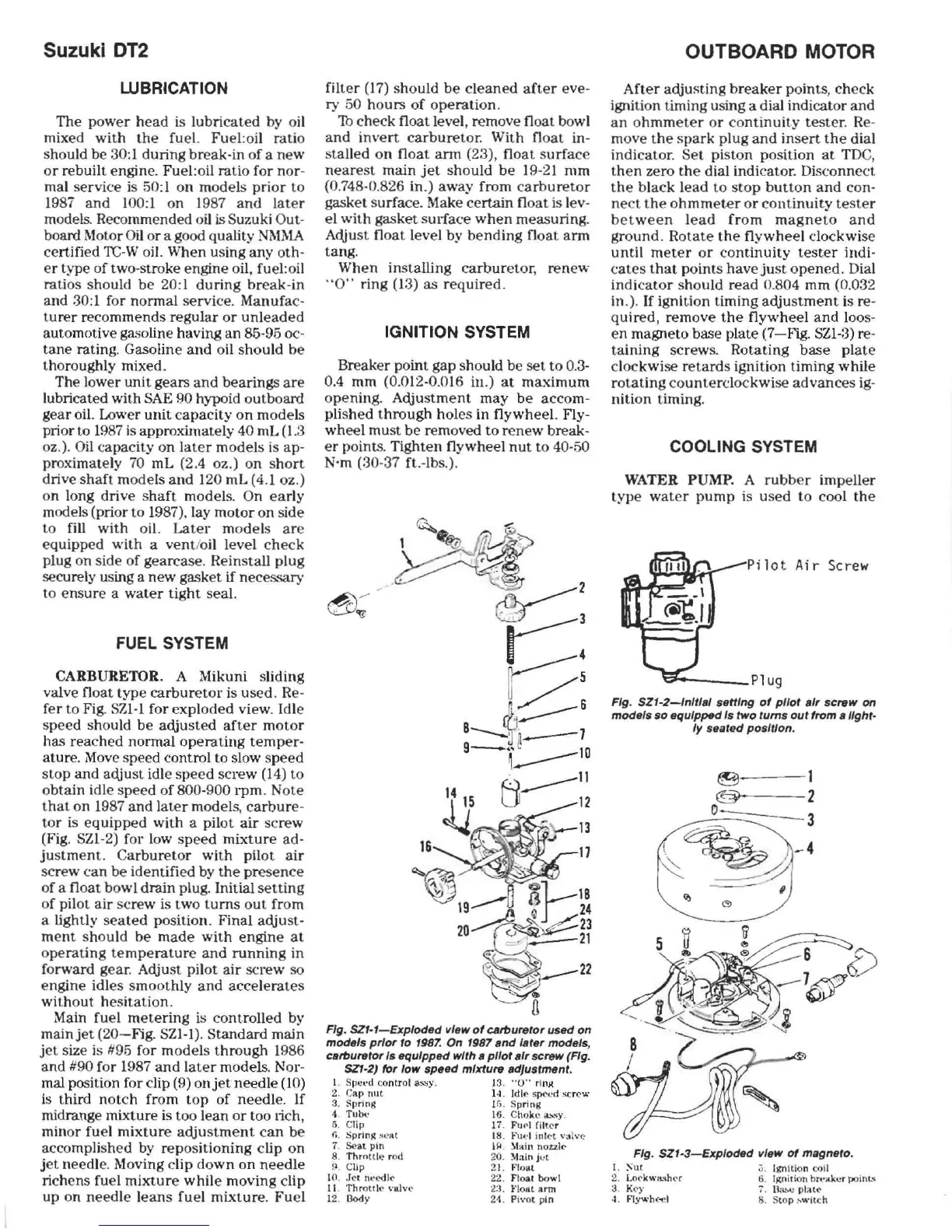

After

adjusting

breaker

points,

check

ignition timing using a dial indicator

and

an

o

hmmeter

or

continuit.y

tester

.

Re

-

move

the

spark

plug

and

insert

the

dial

indicator.

Set

piston position

at

TOC,

then

zero

the

dial

indicator

. Disconnect

the

black

lead

to

stop

button

and

con-

ne

ct

the

ohmmet.er

or

continuity

tester

between

lead

from

magneto

and

ground.

Rotate

the

flywheel

clockwise

until

meter

or

continuity

tester

indi-

cates

that

points

have

just

opened.

Dial

indicator

should

read

0.804 mm (0.032

in.).

If

ignition timing

adjustment

is re-

quired,

remove

the

flywheel

and

loos-

en

magneto base plate

(7-Fig.

SZI-3) re-

taining

screws. Rotating

base

plate

clockwise

retard

s ignition timing

while

rotating

counterclockwise

advances

ig-

nition

t.iming.

COOLING SYSTEM

WATER PUMP. A

rubb

er impeller

type

water

pump

is

used

to

cool

the

Pilot

Ai

r Screw

.......

--_Plug

Fig.

SZI-2-lnltl.'

setting

of

pilot

.,,

screw

on

models

so

equipped Is

/WO

lums

our from

sllghr-

Iy

seared

position.

---

1

---2

セZNMM]ZZZZZMM

3

Fig.

SZI-3-Exploded

vleMf

of

magnero.

t.

セオイ@

2. Lo('KW3!ihN

3. K(')"

4.

fiyBBィ

セQ@

;).

Ignition coil

6.

iセョゥャ

ゥッ

ョ@

bh'ilk(!r

po

inL"

lJ.a

..

">(!

pl;lle

B. S

top

セキゥエ」ィ@

Download this Manual

Loading...

Loading...