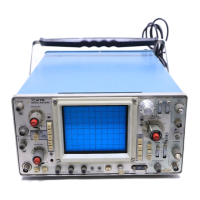

Maintenance—475

Most spray circuit coolants and contact cleaners contain

Freon 12 as a propellant. Because many Freons adversely

affect the contacts, check the contents before using a spray

cleaner or coolant. No Noise (Electronic Chemical) is an

acceptable contact cleaner-restorer. The only recommended

circuit coolants are dry ice or isopropyl alcohol. There are

three recommended switch lubricants. They are Silicone

Versilube (General Electric Co.), Rykon R (Standard Oil),

and WD-40 (Rocket Chemical Co.).

Exterior. Loose dust accumulated on the outside of the

475 can be removed with a soft cloth or small paint brush.

The paint brush is particularly useful for dislodging dirt on

and around the front-panel controls. Dirt which remains

can be removed with a soft cloth dampened in a mild

detergent and water solution. Abrasive cleaners should not

be used.

CRT. Clean the blue and clear plastic light filters and

the CRT face with a soft, lint-free cloth dampened with

denatured alcohol or a mild detergent and water solution.

The optional CRT mesh filter can be cleaned in the

following manner.

1. Hold the filter in a vertical position and brush lightly

with a soft No. 7 watercolor brush to remove light coatings

of dust and lint.

2. Greasy residues or dried-on dirt can be removed with

a solution of warm water and a neutral pH liquid detergent.

Use the brush to lightly scrub the filter.

3. Rinse the filter thoroughly in clean water and allow

to air dry.

4. If any lint or dirt remains, use clean low-pressure air

to remove. Do not use tweezers or other hard cleaning tools

on the filter as the special finish may be damaged.

5. When not in use, store the mesh filter in a lint-free

dust-proof container such as a plastic bag.

Interior. Dust in the interior of the instrument should

be removed occasionally due to its electrical conductivity

under high-humidity conditions. The best way to clean the

interior is to blow off the accumulated dust with dry,

low-pressure air. Remove any dirt that remains with a soft

paint brush or a cloth dampened with a mild detergent and

water solution. A cotton-tipped applicator is useful for

cleaning in narrow spaces or for cleaning circuit boards.

Lubrication

The fan motor and most of the potentiometers used in

the 475 are permanently sealed and generally do not

require periodic lubrication. The switches used in the 475,

both cam- and lever-type, are installed with proper lubrica

tion applied where necessary and will only rarely require

any additional lubrication. It is recommended that a regular

periodic lubrication program not be performed on any of

the components used in the 475.

Transistor Checks

Periodic checks of the transistors and other semi

conductors in the 475 are not recommended. The best

check of semiconductor performance is actual operation in

the instrument.

Recalibration

To assure accurate measurements, check the calibration

of this instrument after each 1000 hours of operation or

every six months if used infrequently. In addition, replace

ment of components may necessitate recalibration of the

affected circuits. Complete calibration instructions are

given in the Calibration section.

The calibration procedure can also be helpful in local

izing certain troubles in the instrument. In some cases,

minor troubles may be revealed or corrected by recalibra

tion.

CORRECTIVE MAINTENANCE

General

Corrective maintenance consists of component replace

ment and instrument repair. Special techniques required to

replace components in this instrument are given here.

Obtaining Replacement Parts

Standard Parts. All electrical and mechanical part re

placements for the 475 can be obtained through your local

TEKTRONIX Field Office or representative. However,

many of the standard electronic components can be

obtained locally in less time than is required to order them

from Tektronix, Inc. Before purchasing or ordering replace

ment parts, check the parts list for value, tolerance, rating,

and description.

NOTE

When selecting replacement parts, it is important to

remember that the physical size and shape of a

component may affect its performance in the instru-

4-2

®

Loading...

Loading...