26

Important When adding oil to the hydraulic system,

use a funnel with a fine wire screen—200 mesh—and

ensure funnel and oil are immaculately clean. This

procedure prevents accidental contamination of the

hydraulic system.

3. Screw dipstick filler cap finger–tight onto filler neck. It

is not necessary to tighten cap with a wrench.

4. Lower the implement.

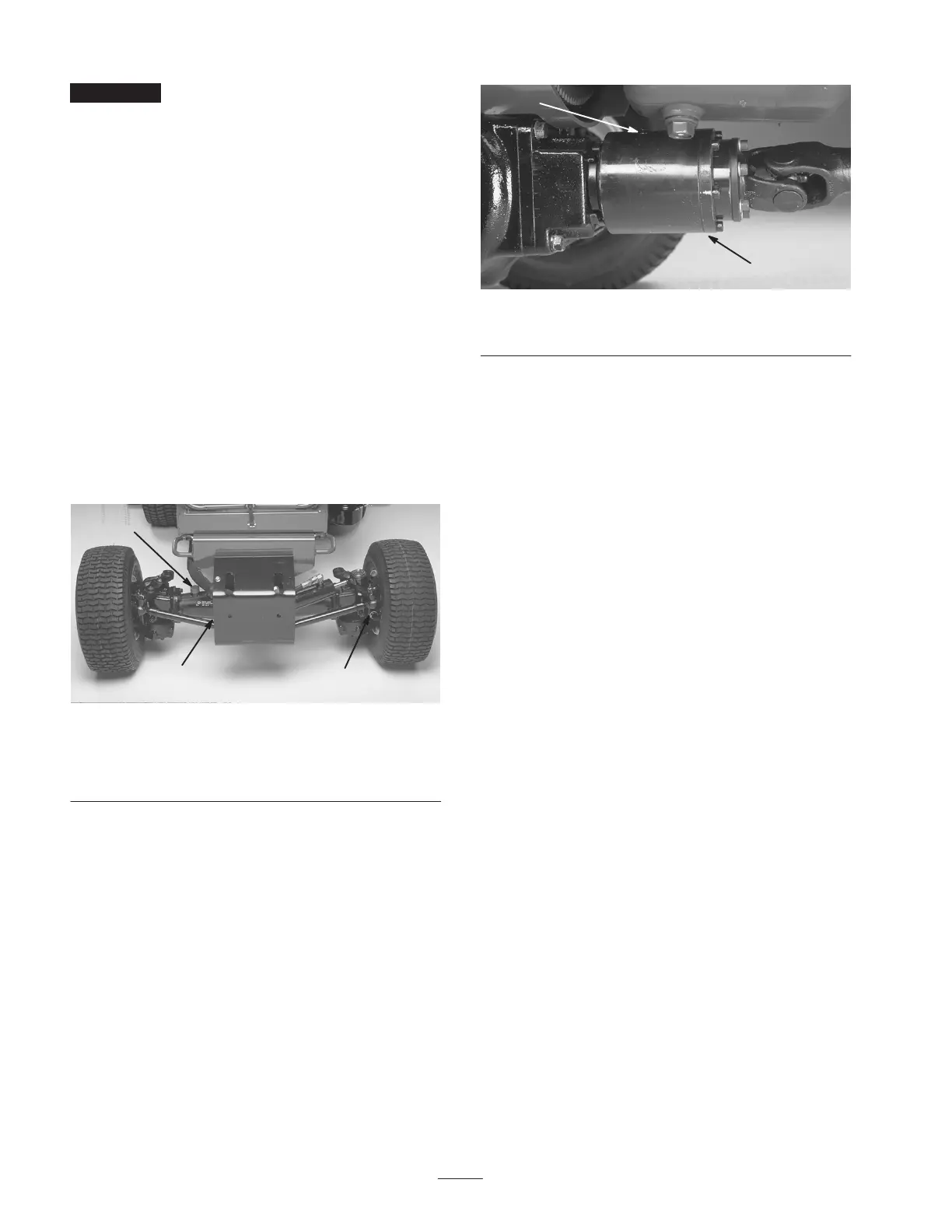

Checking the Rear Axle

The rear axle has three separate reservoirs which use SAE

80W-90 wt. gear lube. Although the axle is shipped with

lubricant from the factory, check the level before operating

the machine.

1. Position the machine on a level surface.

2. Remove check plugs from axle and make sure lubricant

is up to bottom of each hole. If level is low, remove fill

plugs and add enough lubricant to bring the level up to

the bottom of the check plug holes (Fig. 26).

1

2

3

Figure 26

1. Check plug

2. Fill/check plug (one on

each end of axle)

3. Fill plug

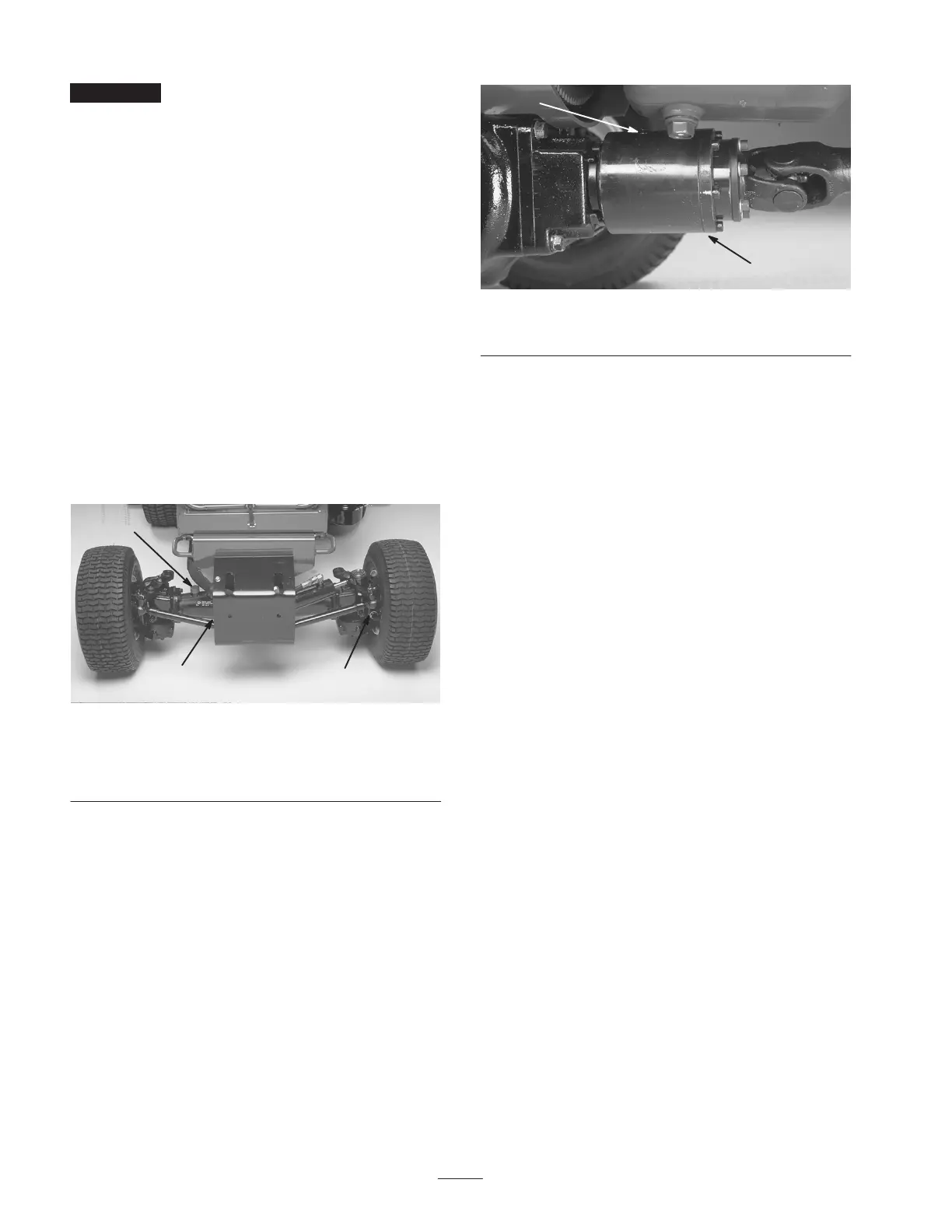

Check Bidirectional Clutch

Lubricant

(Models 30627 & 30631 only)

1. Position the machine on a level surface.

2. Rotate clutch (Fig. 27) so check plug (shown in 12

o’clock position) is positioned at 4 o’clock.

1

2

Figure 27

1. Bidirectional clutch 2. Check plug

3. Remove check plug. Fluid level should be up to hole in

clutch. If fluid level is low, add Mobil Fluid 424. Clutch

should be approximately 1/3 full.

4. Install check plug.

Note: Do not use engine oil (i.e. 10W30) in bidirectional

clutch. Anti-wear and extreme pressure additives will cause

undesirable clutch performance.

Loading...

Loading...