FilteringClosed−LoopTractionCircuit

Filteringofaclosed−loophydraulicsystemafteramajorcomponentfailure(e.g.

traction(piston)pumporfrontwheelmotor)isarequirementtopreventdebris

fromtransmittingthroughoutthesystem.Ifaclosed−loophydraulicsystem

lteringtoolisnotusedtoensuresystemcleanliness,repeatfailures,aswellas

subsequentdamagetootherhydrauliccomponentsintheaffectedsystem,will

occur.Toeffectivelyremovecontaminationfromclosed−looptractioncircuit,use

oftheTorohighowhydrauliclterandhydraulichosekitsarerecommended

(seeSpecialT ools(page2–16)).

1.Parkmachineonalevelsurfacewithenginestoppedandkeyremoved

fromignitionswitch.

2.Raiseandsupportmachinesoallwheelsareofftheground(seeJacking

Instructions(page1–7)).

Note:Iffrontwheelorrearaxlemotorwasreplaced,installhighowlterto

theinletofnewmotorinsteadoftothetractionpumptting.Thiswillprevent

systemcontaminationfromenteringanddamagingthenewmotor.

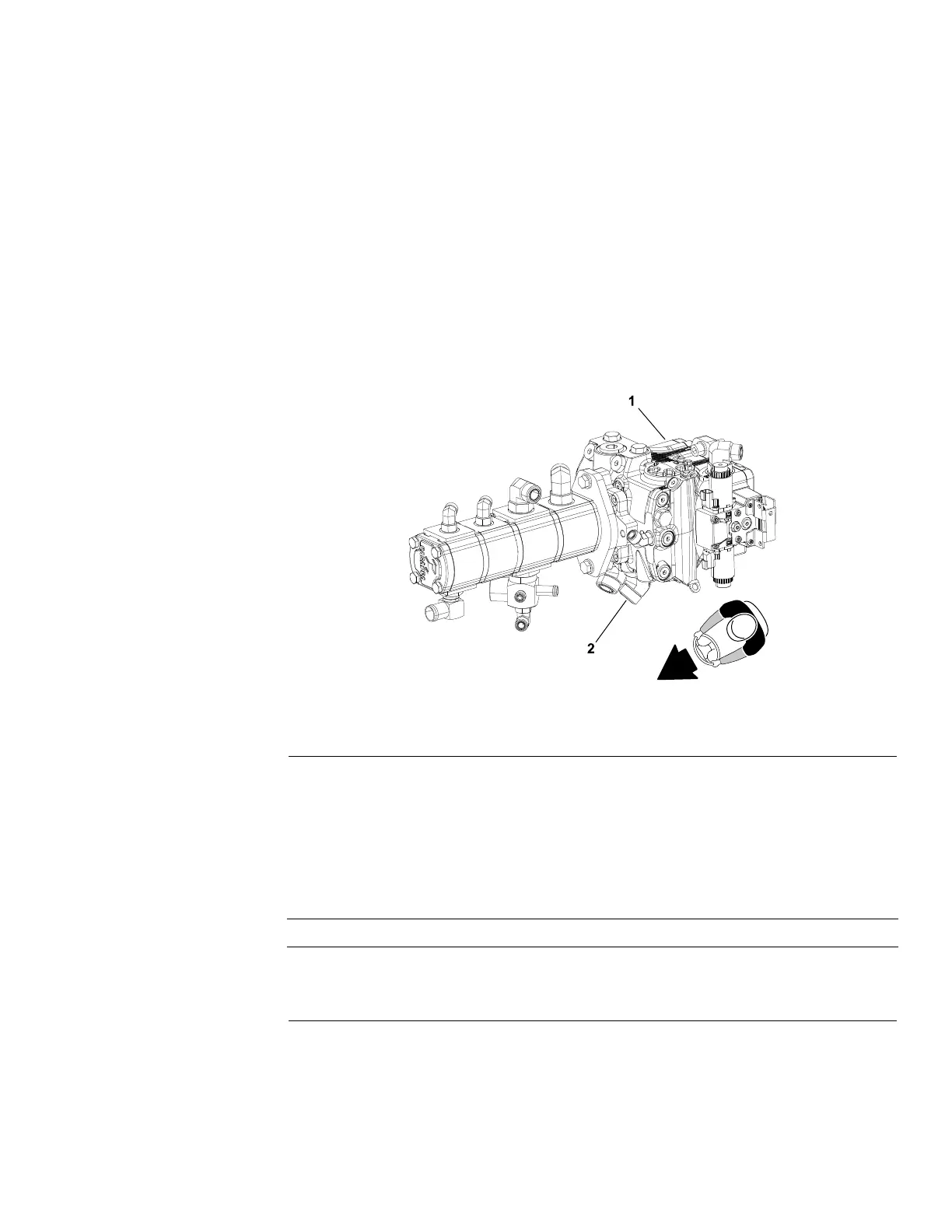

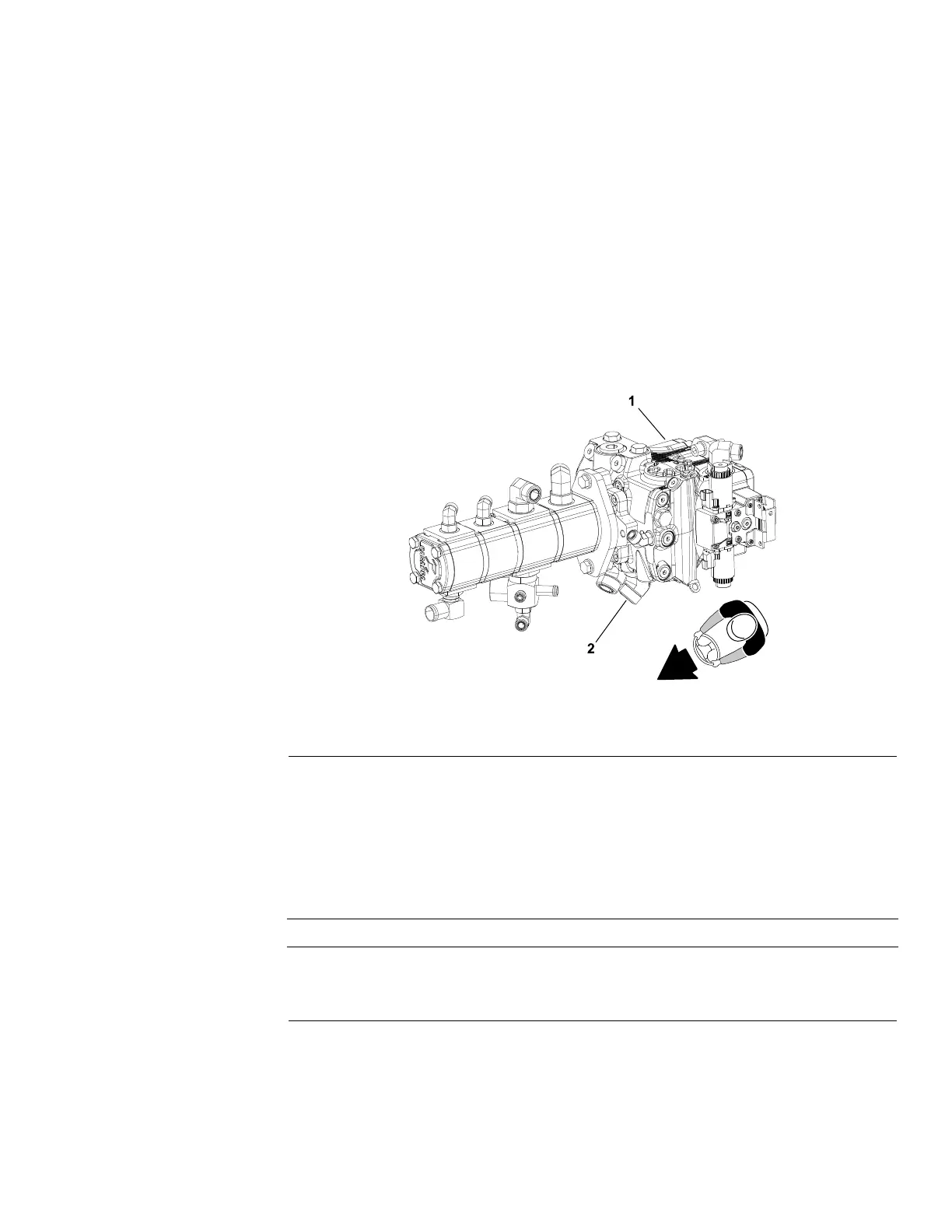

g308653

Figure95

1.Piston(traction)pump2.Leftsidetting

3.Thoroughlycleanjunctionofhydraulichoseandleftsidettingonbottom

ofpiston(traction)pump(Figure95).Disconnecthosefromleftsidepump

tting.

4.ConnectT orohighowhydrauliclterinseriesbetweenpistonpump

ttinganddisconnectedhose.Usehydraulichosekit(seeSpecialT ools

(page2–16))toconnectltertomachine.Makesurethatttingandhose

connectionsareproperlytightened.

IMPORTANT

Whenllinghydraulicreservoir,useonlyhydraulicuidsspecied

inOperator’sManual.Otheruidscouldcausesystemdamage.

5.Afterinstallinghighowltertomachine,checkandllhydraulicreservoir

withnewhydraulicoilasrequired.

6.Startengineandrunatidlespeed.Checkforanyhydraulicleakagefrom

lterandhoseconnections.Correctanyleaksbeforeproceeding.

Groundsmaster

®

4500-D/4700-D

Page5–93

HydraulicSystem:ServiceandRepairs

19245SLRevA

Loading...

Loading...