RT-SVX060D-GB

18

4 UNT-PRC002-GB

Technical Data

FWD 08 12 20 30 45

Power supply (V/Ph/Hz) 230/1/50

Capacities

Cooling capacity on water (1) (kW) 5,2 8,3 15 18,8 30,1

Heating capacity on water (2) (kW) 6,3 11,9 18,9 20,9 38,2

Fan motor (type) 2 x direct drive centrifugal

Fan power input (3) (kW) 0,23 0,46 0,65 1,04 1,51

Current amps (3) (A) 1,1 2,2 3,1 4,7 5,5

Start-up amps (A) 3,2 5,5 9,3 14,1 16,5

Air flow

minimum (m

3

/h) 490 980 1400 1800 2700

nominal (m

3

/h) 820 1650 2300 3000 4500

maximum (m

3

/h) 980 1970 2600 3600 5400

Main coil

Water entering/leaving connections (type) ISO R7 rotating female

(Dia) 3/4" 3/4" 1 1/2" 1 1/2" 1 1/2"

Electric heater (accessory for blower only)

Electric power supply (V/Ph/Hz) 230/1/50 230/1/50 or 400/3/50 400/3/50 400/3/50 400/3/50

Heating capacity (kW) 2/4 8 10 12 12

Hot water coil (accessory for blower only)

Heating capacity (4) (kW) 6,3 12 17,4 22,4 34,5

G2 filter (filter box accessory)

Quantity 2 2 2 2 2

Dimensions ( LxWxth) (mm) 386x221x8 486x271x8 586x321x8 586*421*8 586*621*8

G4 filter (filter box accessory)

Quantity - 2 2 2 2

Dimensions ( LxWxth) (mm) - 486x264x48 586x314x48 586*414*48 586*614*48

Condensate pump (accessory) (type) Centrifugal

Water flow - lift height (l/h - mm) 24 - 500

Not available for FWD30 and FWD45

Sound level (L/M/H speed)

Sound pressure level (5) (dB(A)) 36/40/43 38/41/44 46/50/53 47/52/57 47/52/58

Sound power level (5) (dB(A)) 46/50/53 48/51/54 56/60/63 57/62/67 57/62/68

Unit dimensions

Width x Depth (mm) 890 x 600 1090 x 710 1290 x 820 1290 x 970 1290 x 1090

Height (mm) 250 300 350 450 650

Shipped unit dimensions

Width x Depth (mm) 933 x 644 1133 x 754 1333 x 864 1333 x 1008 1333*1133

Height (mm) 260 310 360 460 660

Weight (kg) 32 46 61 76 118

Colour galvanised steel

Recommended fuse size

Unit alone (aM/gI) (A) 8/16 8/16 8/16 8/25 8/25

Unit with electric heater (gI) (A) 16 (2kW),25 (4kW) 40 (230V),3*16 (400V) 3*20 3*25 3*25

(1) Conditions: Water entering/leaving temperature: 7/12 °C, Air inlet temperature 27/19°C DB/WB - Nominal air flow

(2) Conditions: Water entering/leaving temperature: 50/45 °C, Air inlet temperature 20°C DB - Nominal air flow

(3) At high speed with nominal air flow.

(4) Water entering/leaving temperature 90/70 °C, air inlet temperature 20 °C DB, Nominal air flow.

(5) A rectangular glass wool duct 1m50 long is placed on the blower.The measurement is taken in the room containing the blower unit.

Heat exchanger operating limits:

FWD:

*water temperature: max 100° C

*absolute service pressure: min 1 bar/max 11 bars

Accessories - Hot water coil:

*water temperature: min. +2° C/max. 100° C

*absolute service pressure: min 1 bar/max 11 bars

General information: The installation must conform to all

local standards and regulations.

Reception of Units

Unit Handling

The unit is supplied on wooden blocks. It is

recommended to check the machine’s condition upon

reception.

There are two ways to handle the unit:

1) Handle the machine using a forklift, in accordance

with applicable safety regulations. Handling of the

unit is prohibited unless forks are longer than the

length of the unit.

2) Use a lifting beam correctly adjusted to t the unit.

The units are supplied on the truck but are not

unloaded. A lifting lug is provided on each corner of the

unit’s base to facilitate handling. 4 shackles and 4 slings

are required.

Use a lifting beam to prevent the cables pressing too

hard on top of the unit during lifting.

Important: For unit to t on the roof curb the wooden

blocks must be removed.

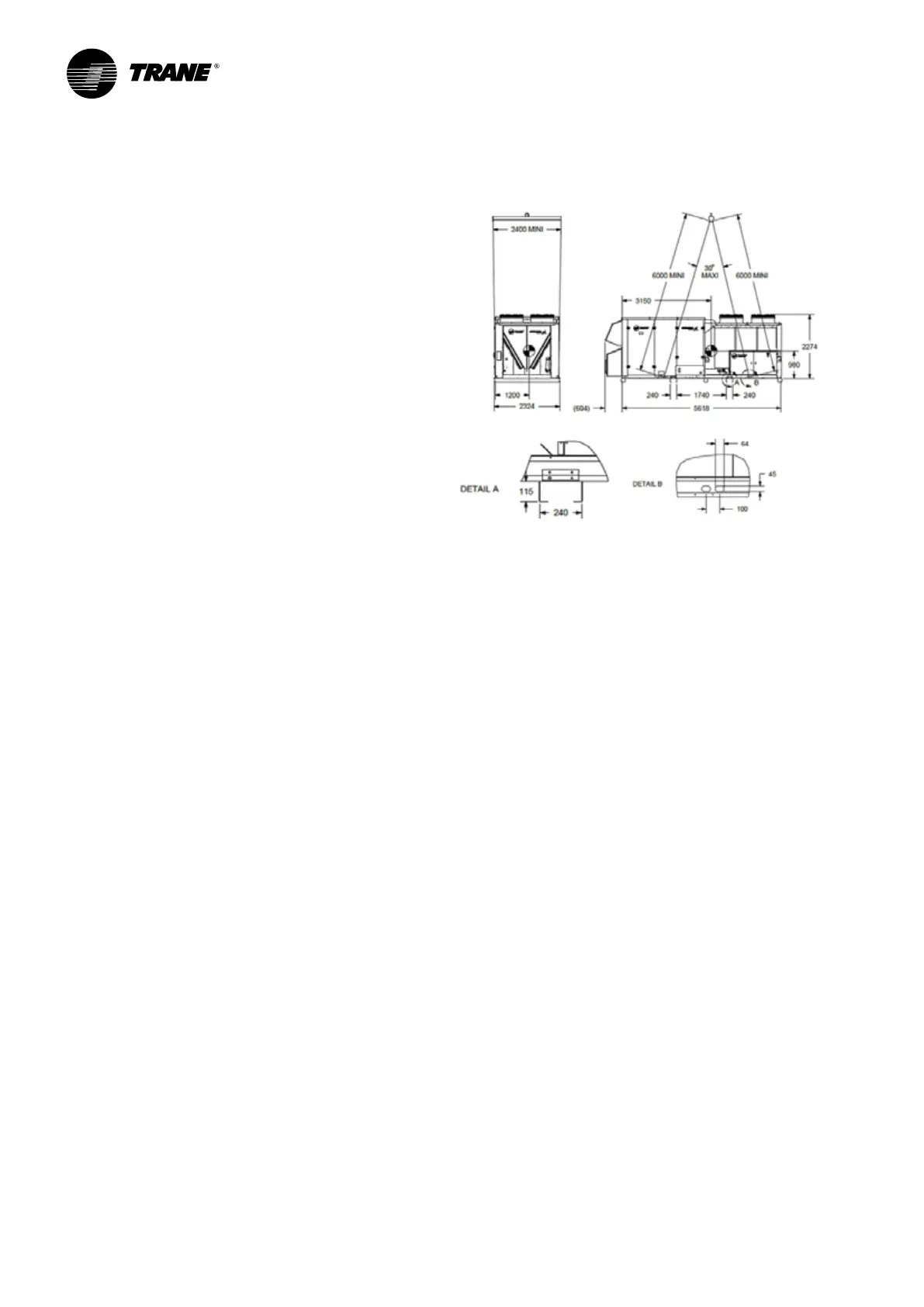

Lifting and moving Instructions

It is recommended to use the special built-in rigging

points shown in the diagram and the following

instructions:

1 - Detailed lifting instructions will be shared along with

unit documentation package.

2 - Use the four rigging points which are built into the

unit.

3 - Slings and a spreader bar are to be provided by the

rigger.

4 - The minimum lifting capacity of each sling (with an

angle of 30° max) as the spreader bar must be equal

or higher than tabulated unit shipping weight.

5 - Caution : This unit must be lifted and handled with

care. Avoid shocks while handing.

Figure 2 - Schematic

of

Lifting drawing

Roof Curb Installation

Roof curb option is not developed by Trane. However it

is possible to use specic roof curb developed case by

case for down ow units. The roof curb should support

the unit and should ensure water tightness.

Installation

Loading...

Loading...