Inspection and maintenance

58 Installation and maintenance instructions ecoTEC 0020173113_01

12

12.3.6 Installing the compact thermal module

a

Danger!

Risk of death and risk of damage caused

by hot flue gas!

If you do not renew the seal and the self-

locking nuts on the burner door, hot flue

gases may escape and cause personal

injury and material damage.

> Replace the seal each time you open the

burner door.

> Replace the self-securing nuts each time

you open the burner door.

> If the burner flange insulation on the

module shows signs of damage other

than small cracks it must be replaced

(article number 193 595).

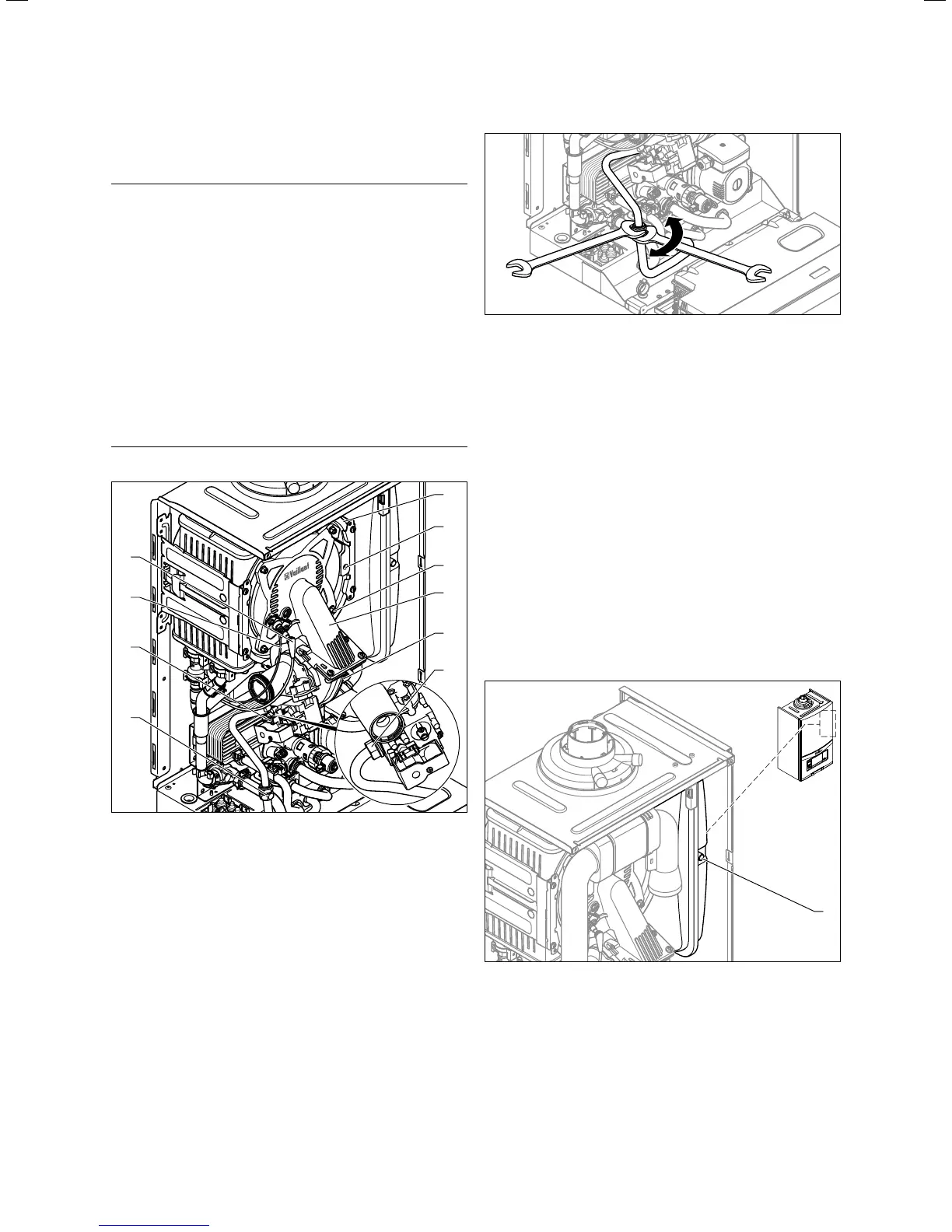

1

2

3

5

10

9

7

8

4

6

12.10 Installing the compact thermal module

> Attach the compact thermal module (4, ¬ fig. 12.10) to

the heat exchanger (1, ¬ fig. 12.10).

> Tighten the four nuts (3, ¬ fig. 12.10) crosswise until the

burner door fits closely and uniformly onto the mating

surfaces (If a torque spanner is available, set at 6Nm).

> Attach the plug of the ignition line (10, ¬ fig. 12.10) and

the ground connection (9, ¬ fig. 12.10) to the ignition

electrode.

> Attach the plug (5, ¬ fig. 12.10) to the fan motor.

> Attach the plug (8, ¬ fig. 12.10) to the gas valve.

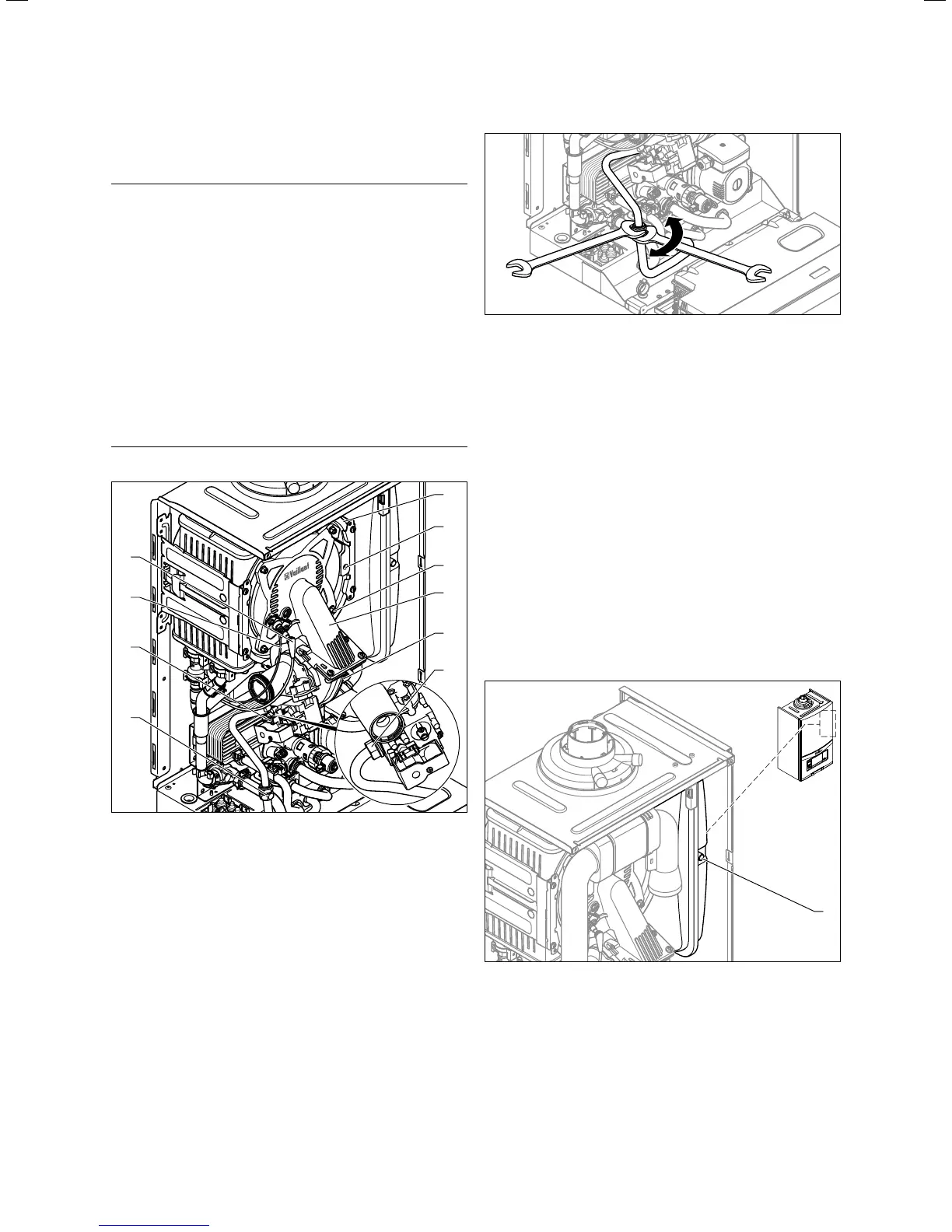

12.11 Secure the gas pipe against twisting

> Tighten either the cap nut (6, ¬ fig. 12.10) on the gas

valve or the cap nut (7, ¬ fig. 12.10) between the gas

pipes. Use a new seal for this.

> Secure the gas pipe against twisting (¬ fig. 12.11) by

holding the pipe against the spanner flat when tighten-

ing the cap nut.

> Open the gas isolator cock on the boiler and ensure

there are no leaks.

> Check that the sealing ring in the air intake pipe is posi-

tioned correctly in the seal seat.

> Insert the air intake pipe (1, ¬ fig. 12.3) back into the

intake stub.

> Attach the air intake pipe using the retaining screw (2,

¬ fig. 12.3).

12.3.7 Checking the charge pressure of the

expansion vessel

1

12.12 Checking the charge pressure of the expansion vessel

The service valves of the boiler must be closed.

> Measure the charge pressure of the expansion vessel at

the testing nozzle (1) of the vessel with the boiler depres-

surised.

> Top up the expansion vessel at a pressure of less than

0.75 bar in accordance with the static height of the heat-

Loading...

Loading...