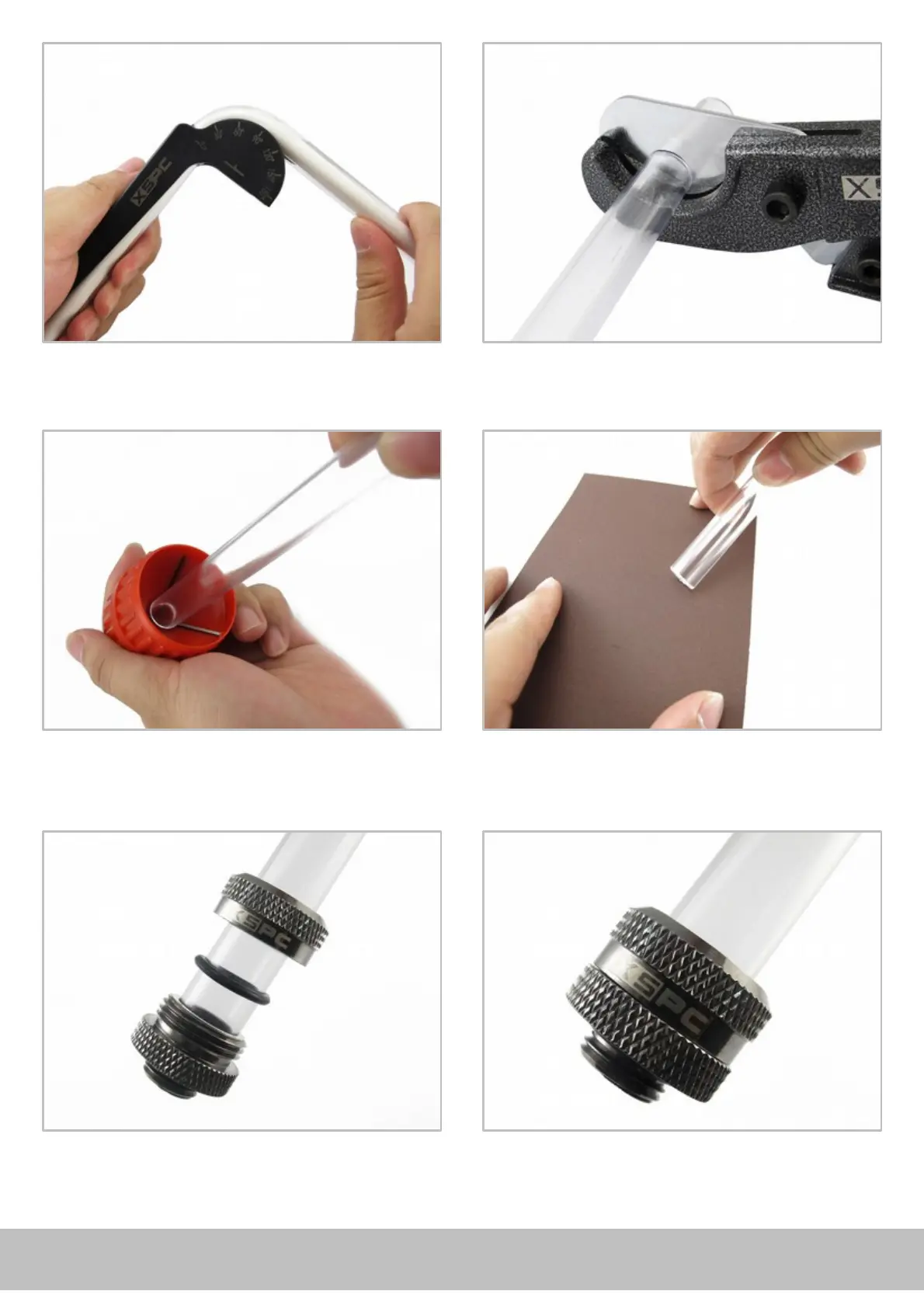

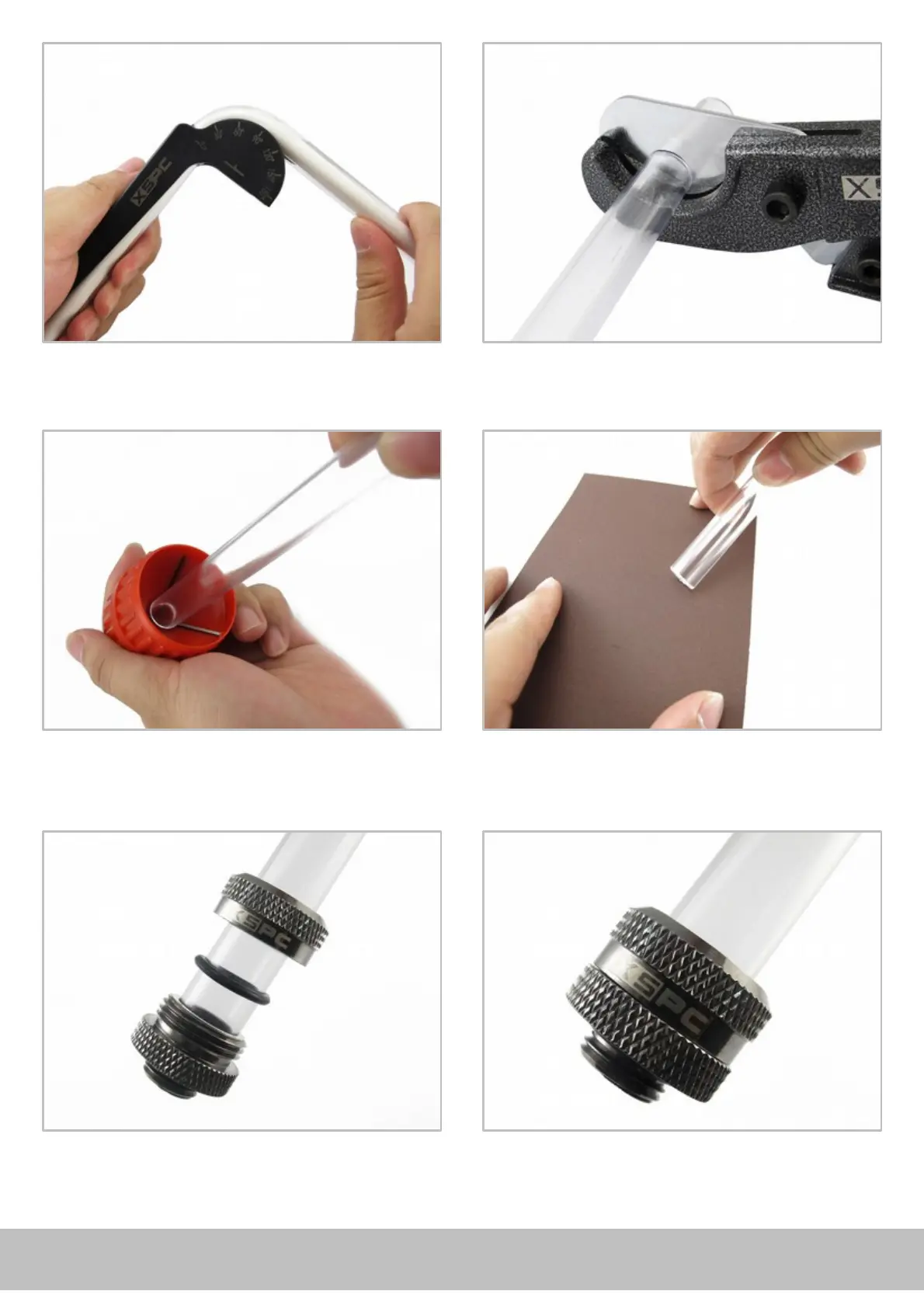

7. Use the chamfer tool to add an edge to each end of

the cut tube. You must only rotate anti-clockwise. If

you turn clockwise the blades will dig into the tube and

give a poor finish.

8. Use the sand paper to clean the chamfered edges

of the tube. Do not sand the sides of the tube as this

may stop the tube sealing in the fitting.

5. Bend the tube over the head of the tool until you get

the desired angle. Hold it steady and allow the tube to

cool before removing it from the tool.

6. Remove the bending rubber and trim the edges of

the PETG tubing to the correct length for your build. To

remove the bending rubber, just twist and pull.

www.xs-pc.com/support

9. Place the compression fittings nut and o-ring over

the PETG tube and push the chamfered end of the

tube into the fitting. You will need to use some force to

get the tubing past the two internal o-rings.

10. Screw the nut down until the fitting is completely

closed and sealed.

Loading...

Loading...