I.L. 41-201.2G

3

TYPE CV FREQUENCY

COMPENSATED VOLTAGE RELAY

3.2.2 Trip Circuit Constants

Indicating Contactor 0.2 amp. Tap, 6.5 ohms

Switch dc resistance

2 amp. tap, 0.15 ohms

dc resistance

4.0 ENERGY REQUIREMENTS

The burdens of the CV-21, CV-22, CV-24, CV-25,

CV-26, CV-27 relays at rated voltage are shown in

Table A.

The burden of the IIV (when used) is in addition to

the above burdens and is as follows:

5.0 SETTINGS

5.1 CV UNIT

The setting of the CV unit can be defined either by

tap setting and time-dial position or by tap setting

and a specific time of operation at some percentage

of tap value voltage (e.g., on CV-24 120 tap setting, 2

times dial position or 120 tap setting, 12 seconds at

140 percent of tap value voltage).

To provide selective circuit breaker operation, a minimum

coordinating time of 0.3 seconds plus circuit breaker time

is recommended between the relay being set and the

relays with which coordination is to be effected.

The connector screw on the terminal plate above the

time dial connects various turns of the operating coil.

By placing this screw in the various terminal plate

holes, the relay will just close its contacts at the cor-

responding voltage of 55-64-70-82-93-105-120-140

volts or as marked on the terminal plate.

The nylon screw on the terminal plate holds the tap

plate in position when taps are being changed. To

use the position on the terminal plate in which the

nylon screw is used, remove the nylon screw and

place it in one of the unused holes. Then remove the

tap screw and insert it in the terminal plate hole.

5.1.1 Instantaneous Reclosing

The factory adjustment of the voltage unit contacts

follow. Where circuit breaker reclosing will be initi-

ated immediately after a trip by the overvoltage con-

tact, the time of the opening of the contacts should

be a minimum. This condition is obtained by loosen-

ing the stationary contact mounting screw, removing

the contact plate and then replacing the plate with

the bent end resting against the contact spring.

For double trip relays, the upper stationary contact is

adjusted such that the contact rests solidly against

the back stop. The lower stationary contact is then

adjusted such that both stationary contacts make

contact simultaneously with their respective moving

contact.

5.2 INSTANTANEOUS INDICATING VOLTAGE

SWITCH (IIV)

The adjustable resistor must be adjusted for the

desired pickup voltage.

5.3 INDICATING CONTACTOR SWITCH (ICS)

Only one setting is required on the ICS unit; that is,

the selection of the 0.2 to 2.0 ampere tap setting.

This selection is made by connecting lead located in

front of the tap block to the desired setting by means

of the connecting screws.

6.0 INSTALLATION

The relays should be mounted on switchboard pan-

els or their equivalent in a location free from dirt,

moisture, excessive vibration and heat. Mount the

relay vertically by means of the rear mounting stud or

studs for the type FT case projection case or by

means of the four mounting holes on the flange for

the semi-flush type FT case. Either the stud or the

mounting screws may be utilized for grounding the

relay. External toothed washers are provided for use

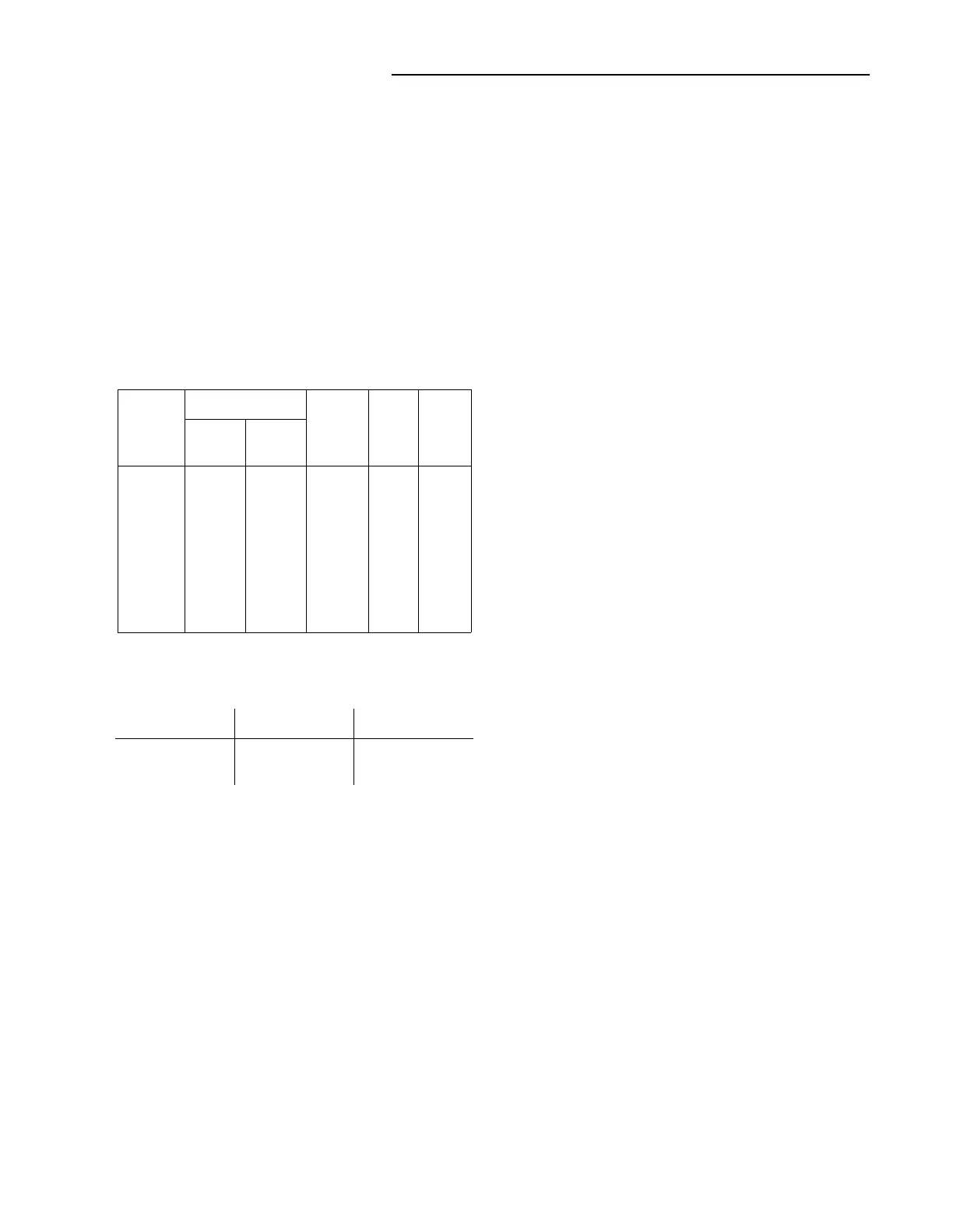

Table A:

Rated

voltage

TAPS

Volt -

Amps.

Power

Factor Watts

120 Volt

Relay

240 Volt

Relay

120 or

240 Volts

55

64

470

82

93

105

120

140

110

128

140

164

186

210

240

280

14.38

10.38

8.35

6.00

4.66

3.64

2.77

2.04

.44

.41

.39

.37

.35

.34

.33

.31

6.3

4.23

3.26

2.23

1.63

1.25

.92

.63

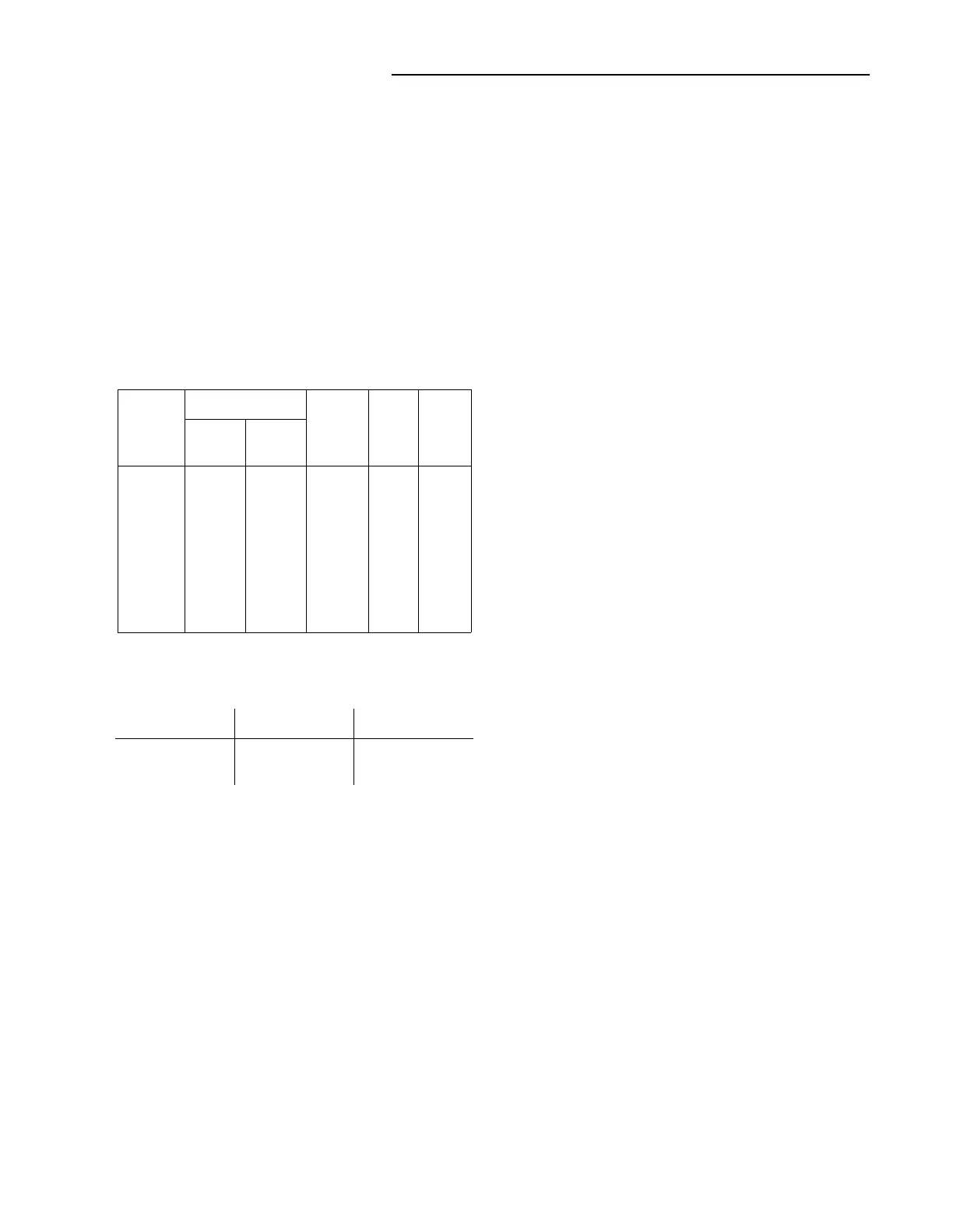

Setting Voltage Applied Burden

120 volts

200 volts

120 volts

200 volts

2.0 V.A.

3.0 V.A.

Loading...

Loading...