7

3. Transport and storage

Packing materials

Table 2. lists all the packing materials used in the switchgear:

Raw material Possible recycling method

Plywood Recycling or disposal

Unplaned wood products Recycling or disposal

Antistatic polythene film Recycling or disposal

Polythene shrink wrap Recycling or disposal

VCI (vapour corrosion inhibitor) film Recycling or disposal

Tape Recycling or disposal

Folded cardboard and polystyrene

reinforcements

Recycling or disposal

Corner protections Recycling or disposal

Table 2. Packing materials

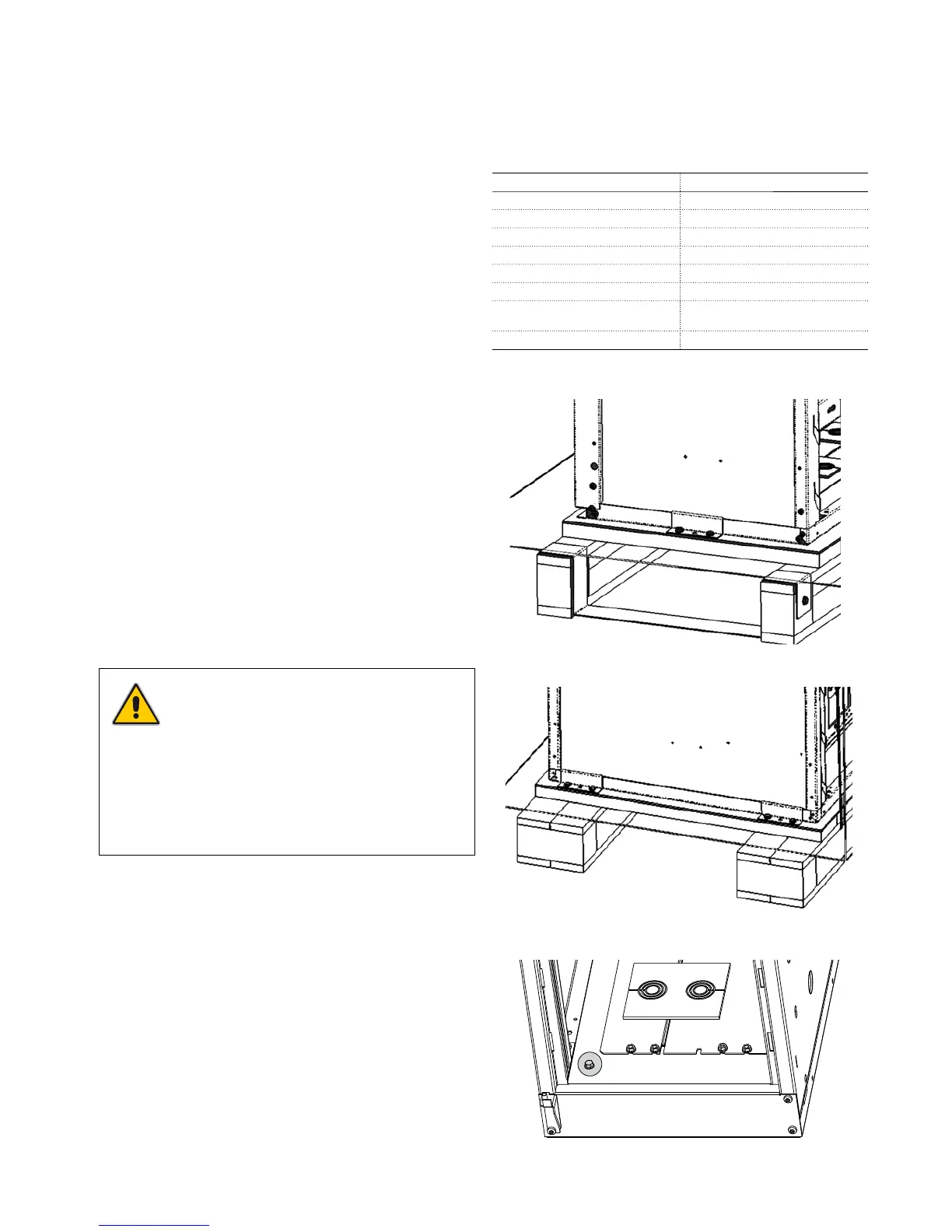

Figure 11. Fixing plates outside the 375-500 mm unit

Figure 12. Fixing plates outside the 750 mm unit

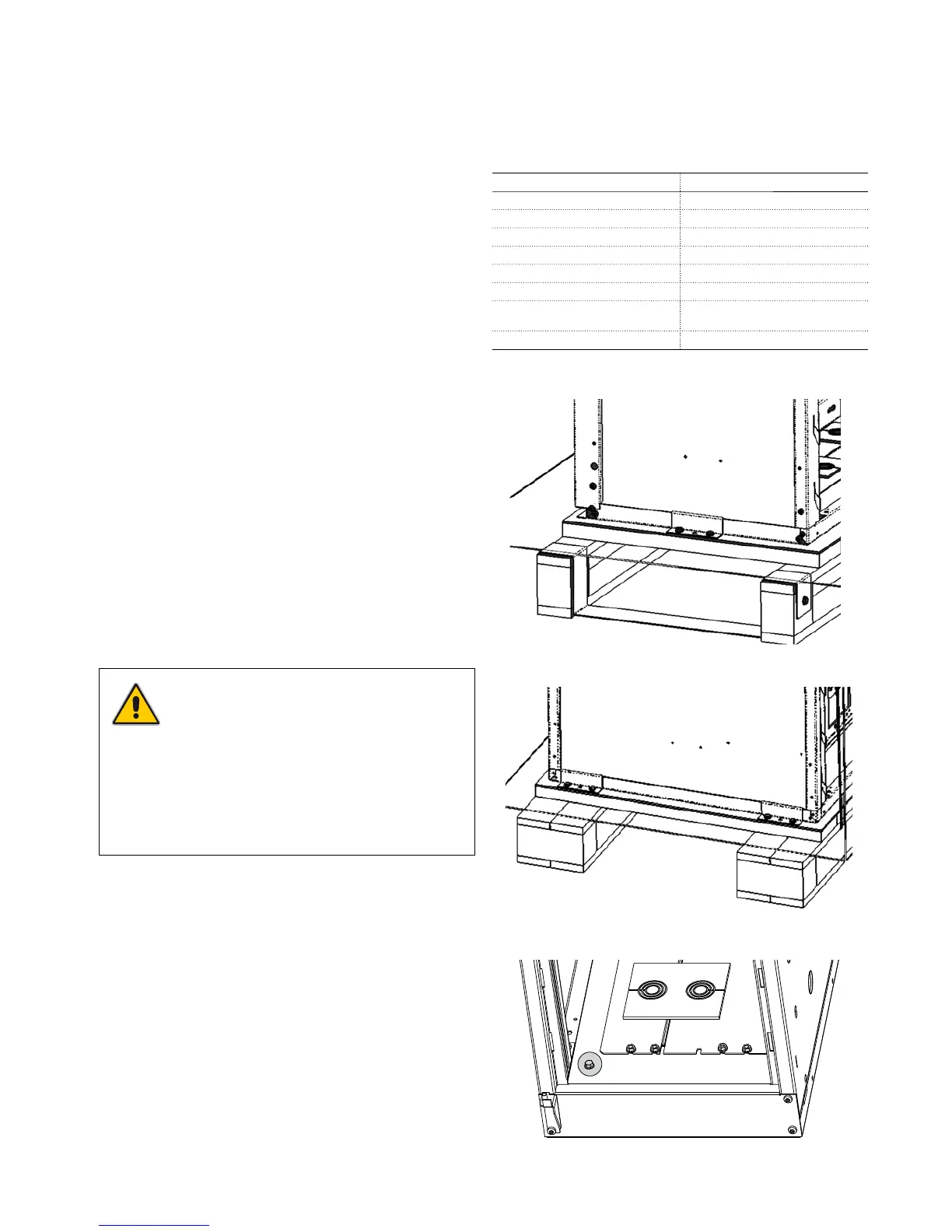

Figure 13. Bolt inside the unit (left side)

3.1 Condition on delivery

Delivery packing

UniSec is delivered either as a single unit or in multiple switch-

gear units with a length of no more than 2.0 m, and with the

doors closed. The size of the pack(s) depends on the number

and type of units and has to be defined separately in each

case.

The factory-assembled units have been inspected by the man-

ufacturer in the factory for completeness in terms of the order

and, at the same time, subjected to routine testing according

to IEC publication 62271-200 in order to verify correct con-

struction and functions.

The branch busbars are factory-assembled for each unit.

However, the main busbar connections between different

units must be carried out on site. The main busbars and their

accessories are packed separately for delivery.

3.2 Unpacking at installation site

Storage and inspection

The UniSec switchgear must only be installed indoors. It is

therefore important to store the switchgear units in their trans-

port packing for as long as possible. Do not store switchgear

units outside.

The packs should only be opened to inspect for any damage

caused during transport. After inspection, the packing should

be restored to its original condition.

NOTE

Any transport damage must be reported to the

carrier/forwarder immediately. If installation

of the switchgear is to be made immediately

after delivery, the transport packing must

be removed, except for the plastic vapour

corrosion inhibitor film covering the units,

which must only be removed at the final

switchgear installation site.

Unpacking

The UniSec units are fixed to the pallet using separate fixing

plates (2 plates on the back of the unit) and bolts (2 bolts on

the front of the unit) inside the unit.

a) Remove the plastic film from the units.

b) Take off and dispose of the fixing plates and bolts as these

will not be needed.

c) The table shows a list of the packing materials used for

the switchgear units and their possible recycling methods.

Packing materials may vary from case to case. The list gives

an indication of the possible packing materials.

Loading...

Loading...