2920 1390 02

4

Instruction book

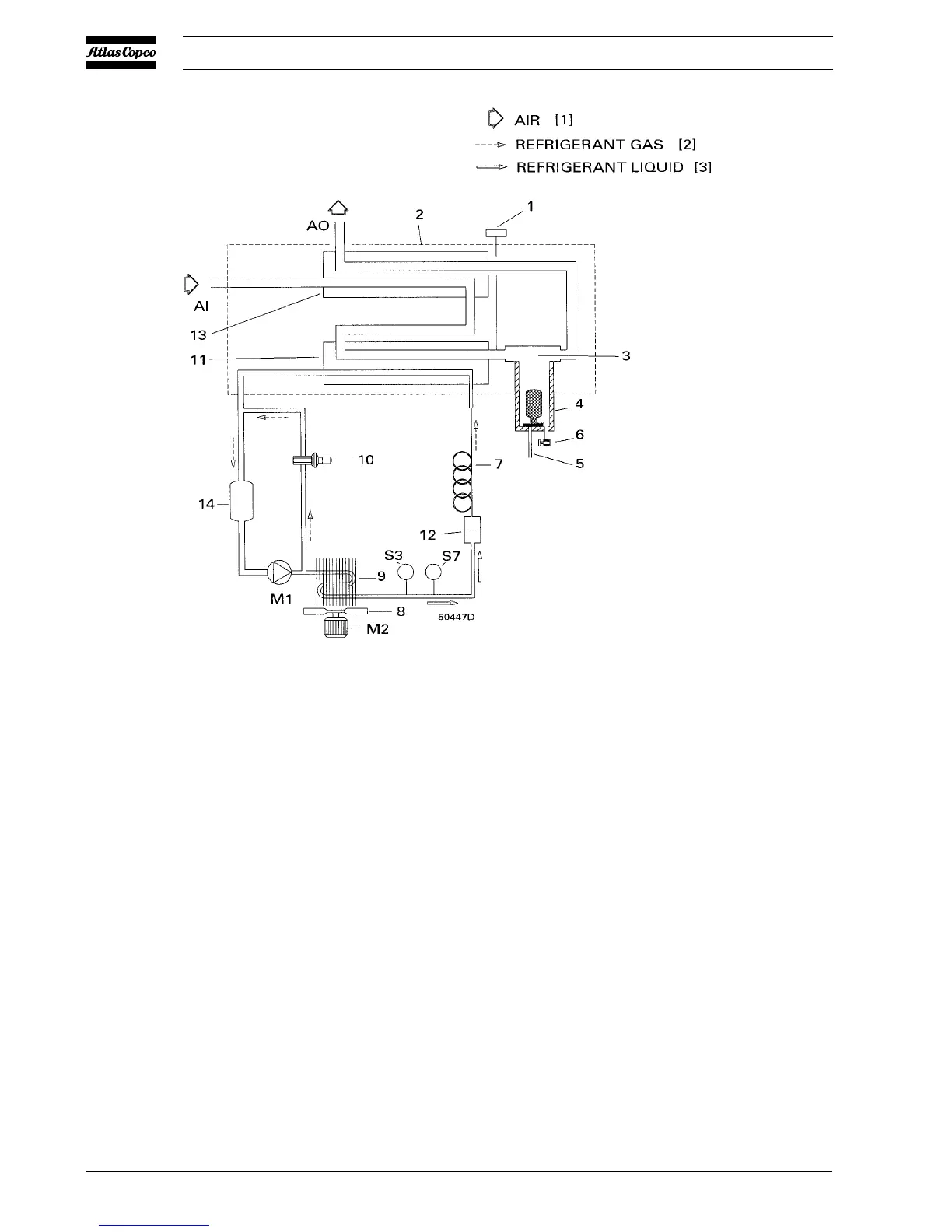

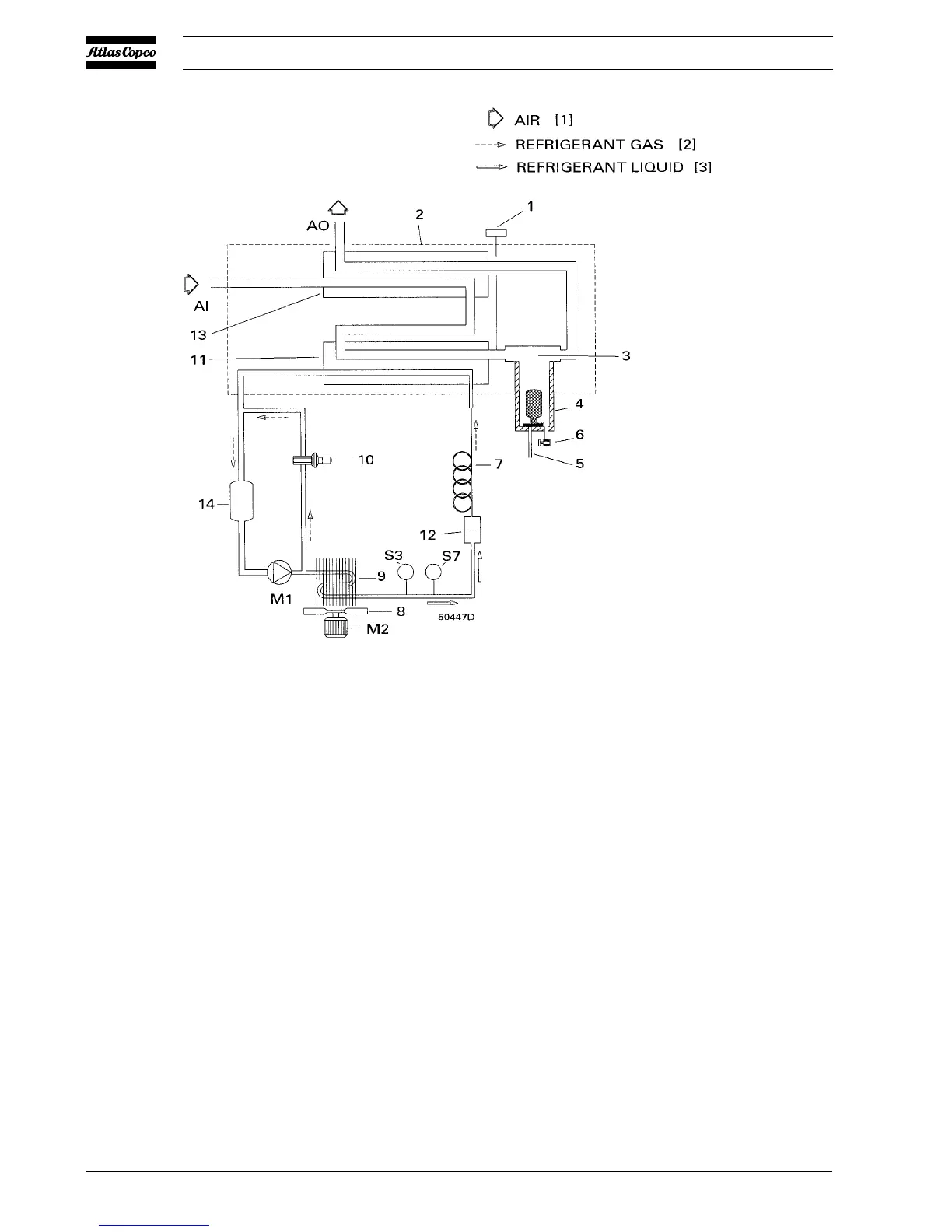

AI. Wet air inlet

AO. Dry air outlet

M1. Refrigerant compressor

M2. Condenser fan motor

S3. Fan control switch

S7. High pressure shut down switch

1. Pressure dewpoint gauge

2. Insulating block

3. Condensate separator

4. Condensate trap

5. Automatic condensate drain hose

6. Manual condensate drain valve

7. Capillary tube

8. Condenser cooling fan

9. Refrigerant condenser

10. Hot gas by-pass valve

11. Air/refrigerant heat exchanger/

evaporator

12. Liquid refrigerant dryer/filter

13. Air/air heat exchanger

14. Accumulator

Fig. 1.2 Air and refrigerant flow diagram

1.4 Automatic regulation system (Fig. 1.2)

The condenser pressure must be kept as constant as possible

to obtain stable operation, therefore, fan control switch (S3)

stops and starts the cooling fan.

When, at partial or no load, the evaporator pressure drops to

2.25 bar(e), the by-pass regulator opens and hot, high pressure

gas is fed to the evaporator circuit to prevent the evaporator

pressure from dropping any further.

1.5 Electrical system (Figs. 1.3 up to 1.6)

FD170 60Hz and FD230 60Hz dryers are 3-phase units, all other

FD dryers are single-phase units.

The refrigerant compressors (M1) of FD170 and FD230 dryers

are equipped with a crankcase heater (Rs). When voltage is

supplied, the heater is energized. It keeps the oil in the crankcase

warm to prevent condensing of refrigerant in the compressor

housing, which could result in serious damage of the compressor

at start (liquid knock).

Loading...

Loading...