Service EN LUM12 HRX/HRX-RE

12

© Atlas Copco Industrial Technique AB - 9836 9388 01

Example

Lubrication Instructions

Rust Protection and Cleaning

Water in the compressed air can cause rust. To prevent rust we strongly recommend to install an air dryer.

Water and particles can cause sticking of vanes and valves. This can be prevented by installing an air fil-

ter close to the product to avoid pressure drop.

Before longer stand stills always protect your tool by adding a few drops of oil into the air inlet. Run the

tool for 5–10 seconds and absorb any access oil at the air outlet in a cloth.

Lubrication of Motor Parts

■

No grease is needed for protected Ball bearings.

■

Apply a thin layer of air tool oil where needed.

Lubrication

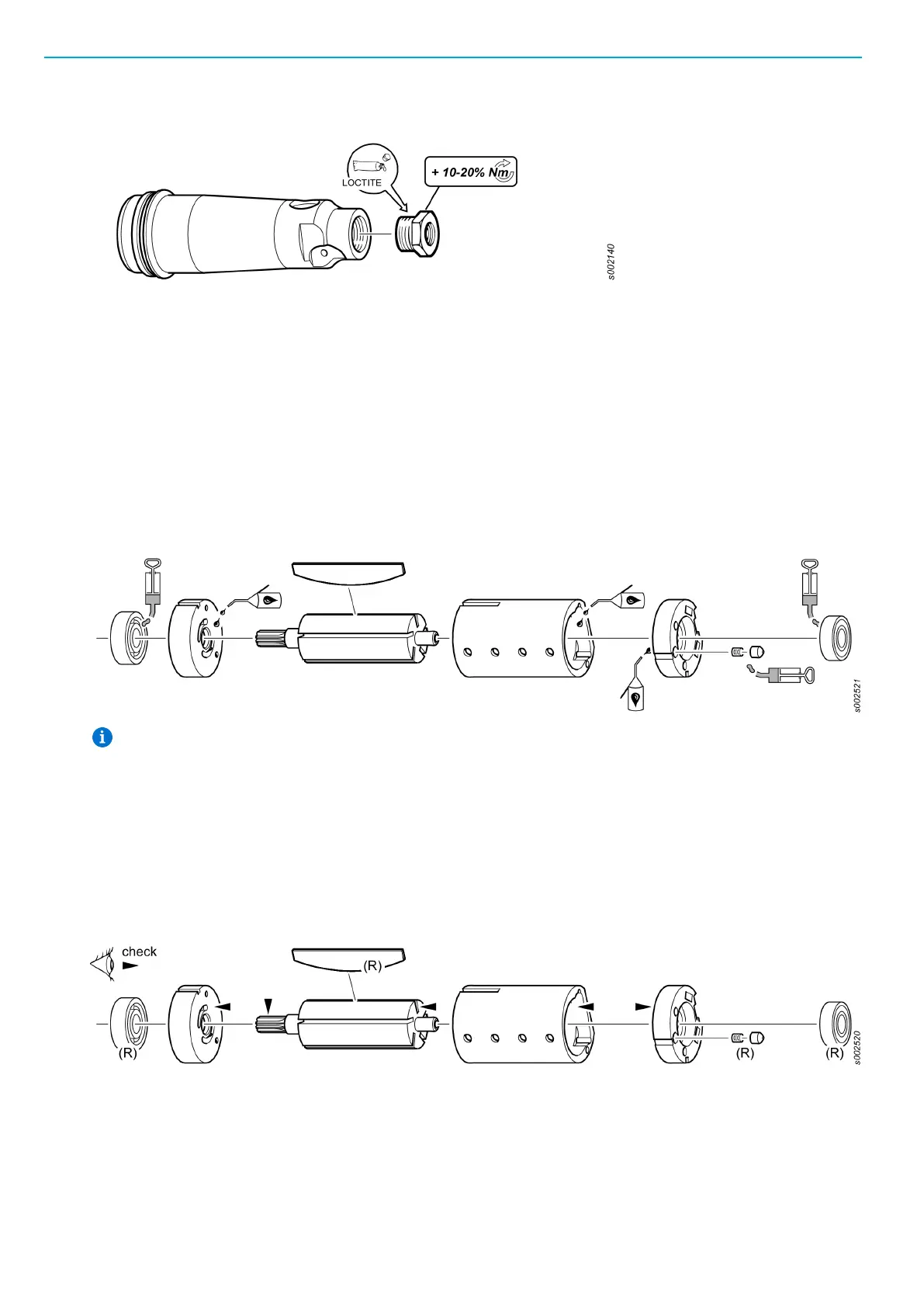

Lubricate specially gears, valve and clutch with grease containing molybdenum disulphide (e.g. Molykote

BR2 Plus). Lubricate o-rings and threaded connections with grease before assembling.

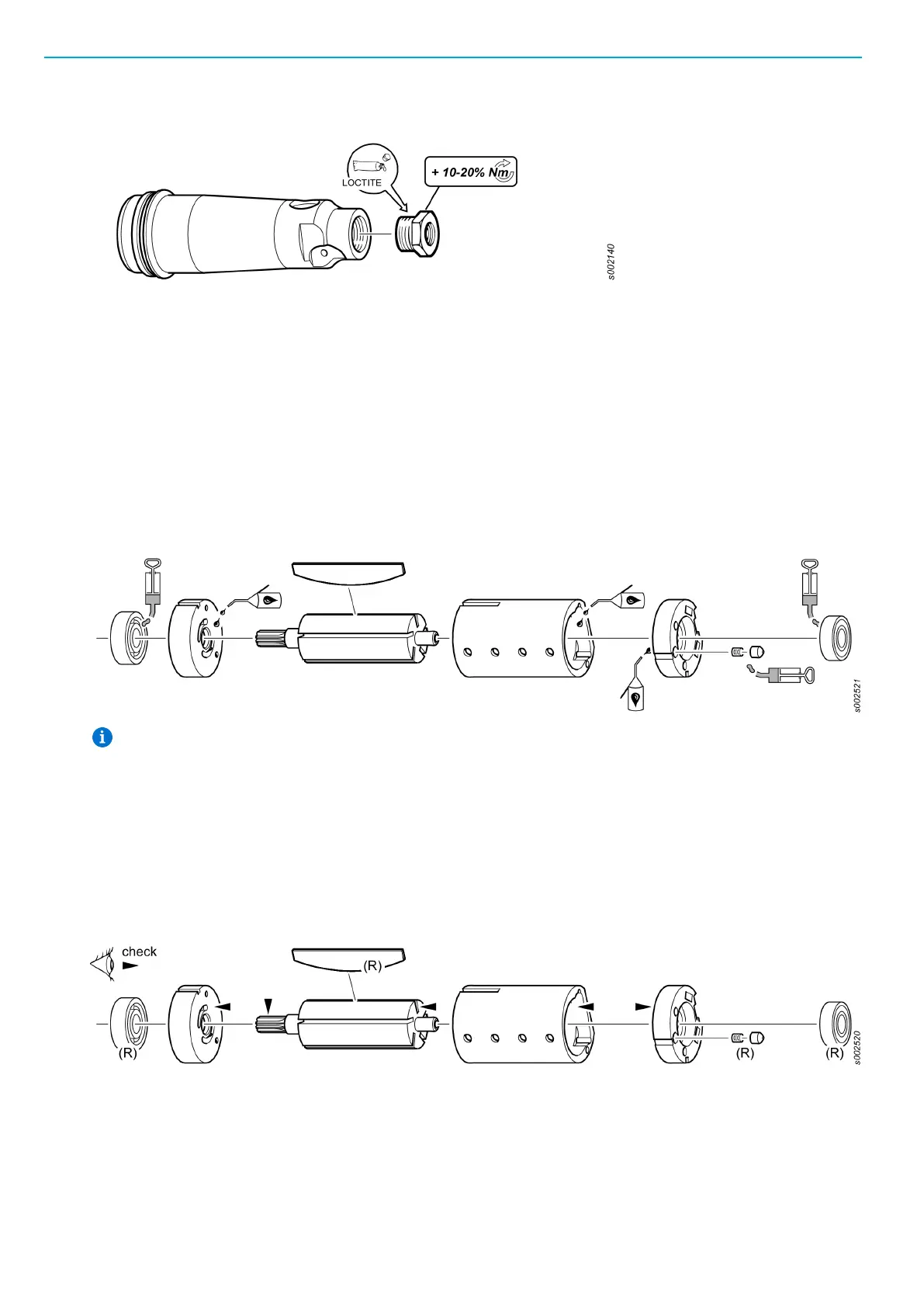

Inspection of Motor Parts

■

(R) To be replaced (from Service kit Ordering No. ) at every overhaul.

■

End plates: Check that they not are scored or scratched. If these are shallow, polish with fine grind-

ing paste against a face plate. Clean thoroughly.

■

Rotor: Check that the end faces do not have any marks or burrs. Check that the splines are not worn

or cracked.

■

Cylinder: Check that the bore is not scored or scratched. If these are shallow, polish with a fine

grinding cloth.

Loading...

Loading...