Instruction book

2920 1472 03 55

6 PROBLEM SOLVING

Warning

Before starting any maintenance or repairs:

- Stop the compressor and close the air outlet valve.

- Press the test buttons (Fig. 1.8) on top of the electronic water drains to depressurize the air

system and open the drain valve (1-Fig. 3.5). If an IMD dryer is installed, open drain valve (8-

Fig. 1.5).

- Open the isolating switch (customer's installation) to switch off the voltage to the compressor.

Apply all relevant safety precautions, including those mentioned in this book.

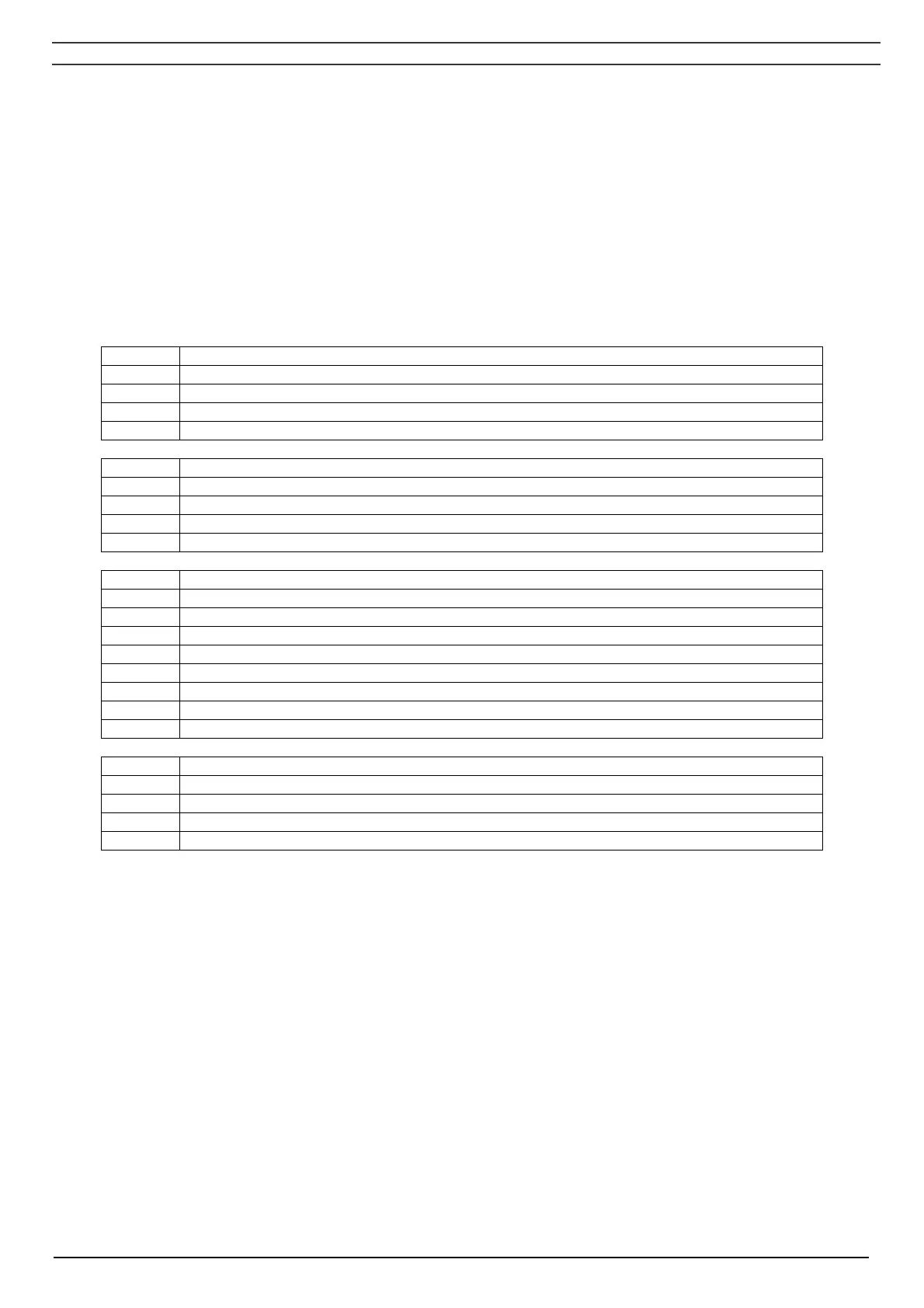

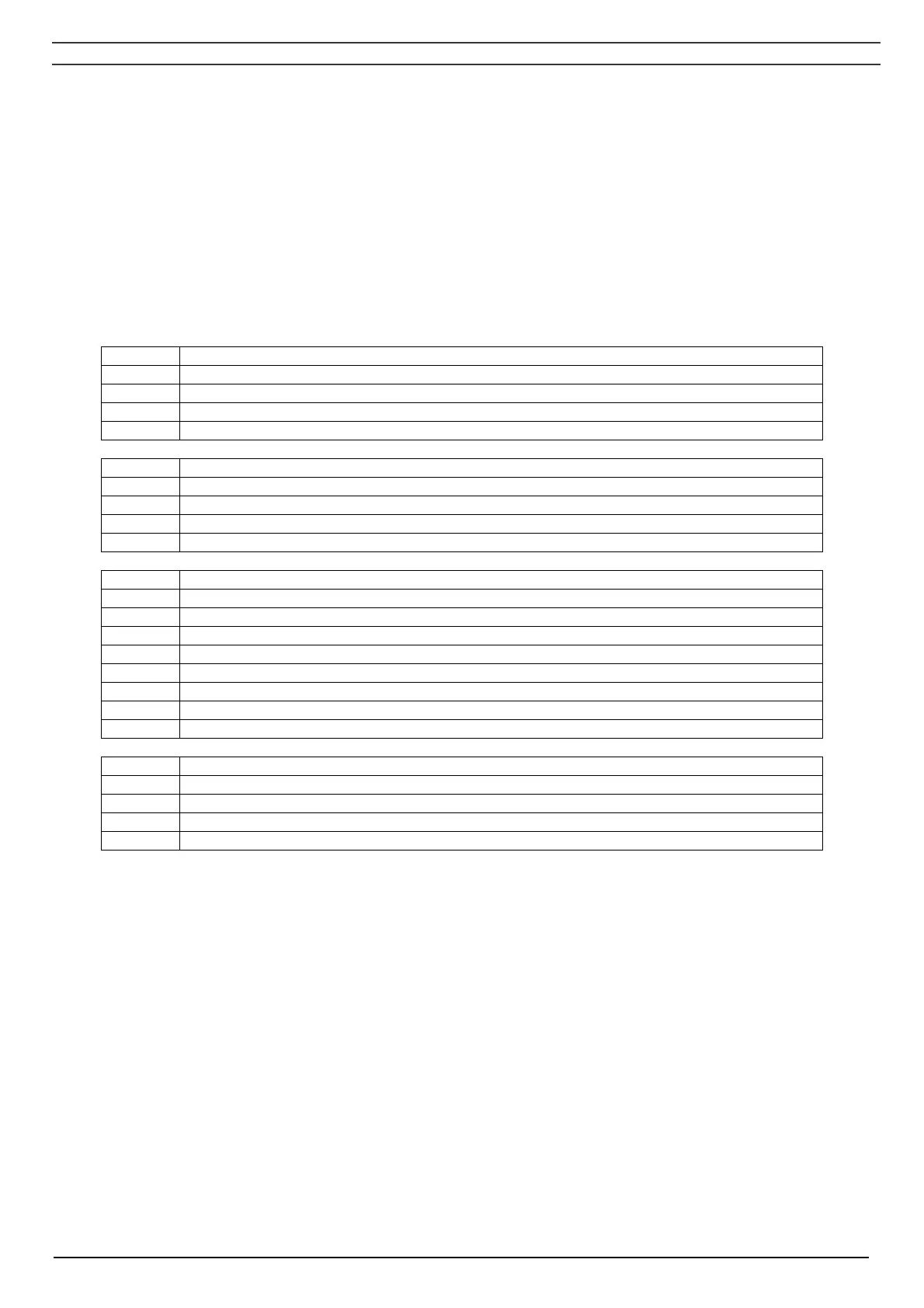

1 Compressor capacity or working pressure lower than normal

a Air consumption exceeds capacity of compressor

a Check pneumatic plant

b Safety valves leaking

b Remove leaking valve and have it inspected

2 Oil pressure too low

a Oil level too low

a Top up level to the middle of the oil level sight-glass

b Oil filter clogged

b Replace filter

3 Air temperature above normal

a Inlet temperature too high due to bad room ventilation or recirculation of cooling air

a Improve ventilation of compressor room and avoid cooling air recirculation

b Air filter clogged

b Replace filter

c On ZR, insufficient cooling water flow

c Check water temperature and increase cooling water flow

d On ZR, restriction in cooling water system due to formation of scale or settling down of dirt

d Consult Atlas Copco

4 Condensate is not discharged from condensate traps during operation

a Discharge flexible clogged

a Check and correct as necessary

b Electronic water drain malfunctioning

b Consult Atlas Copco

Loading...

Loading...