The authorised Technical Assistance Service can convert this boiler to natural gas (G20) or liquid gas (G31).

19. GAS CONVERSION

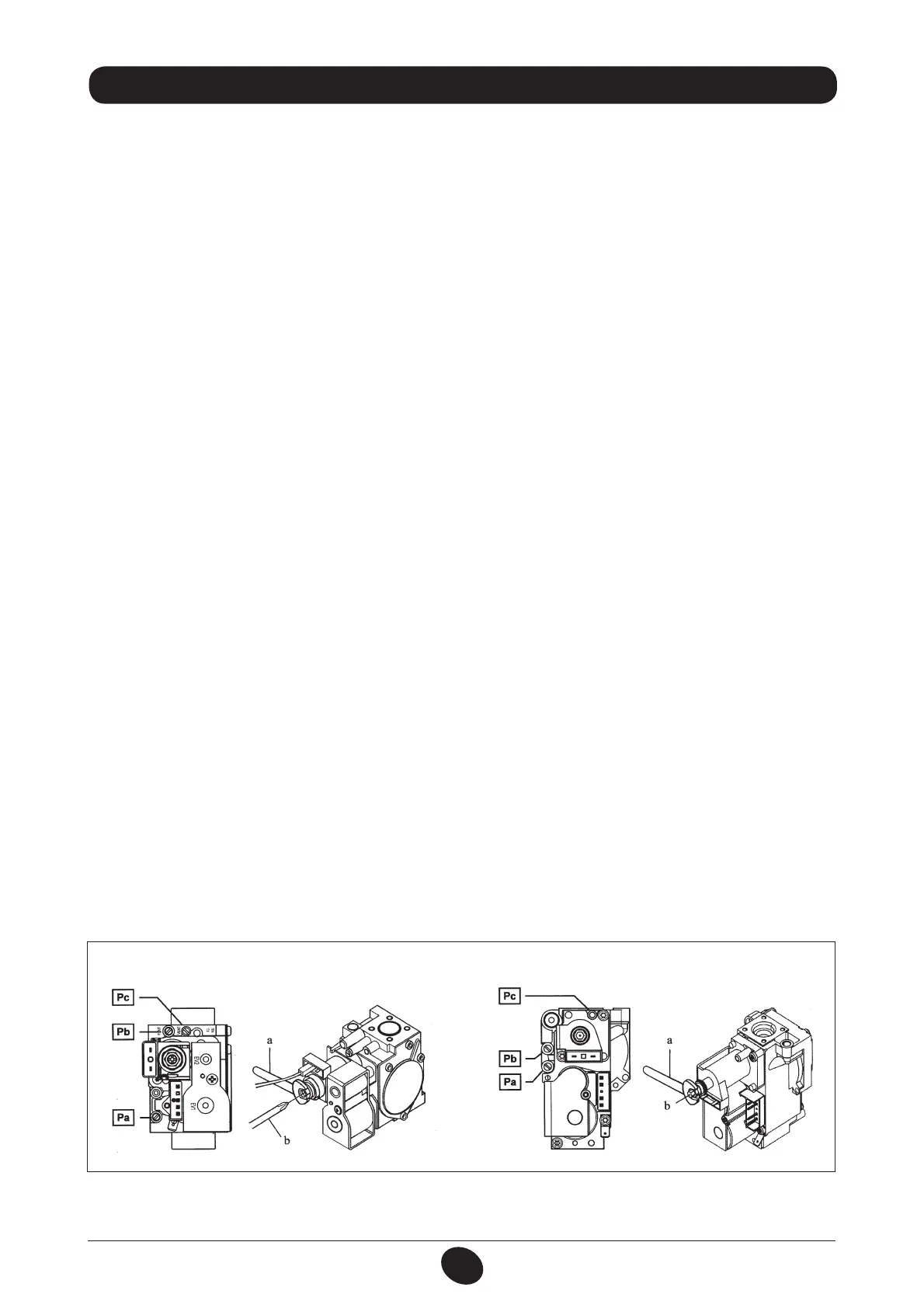

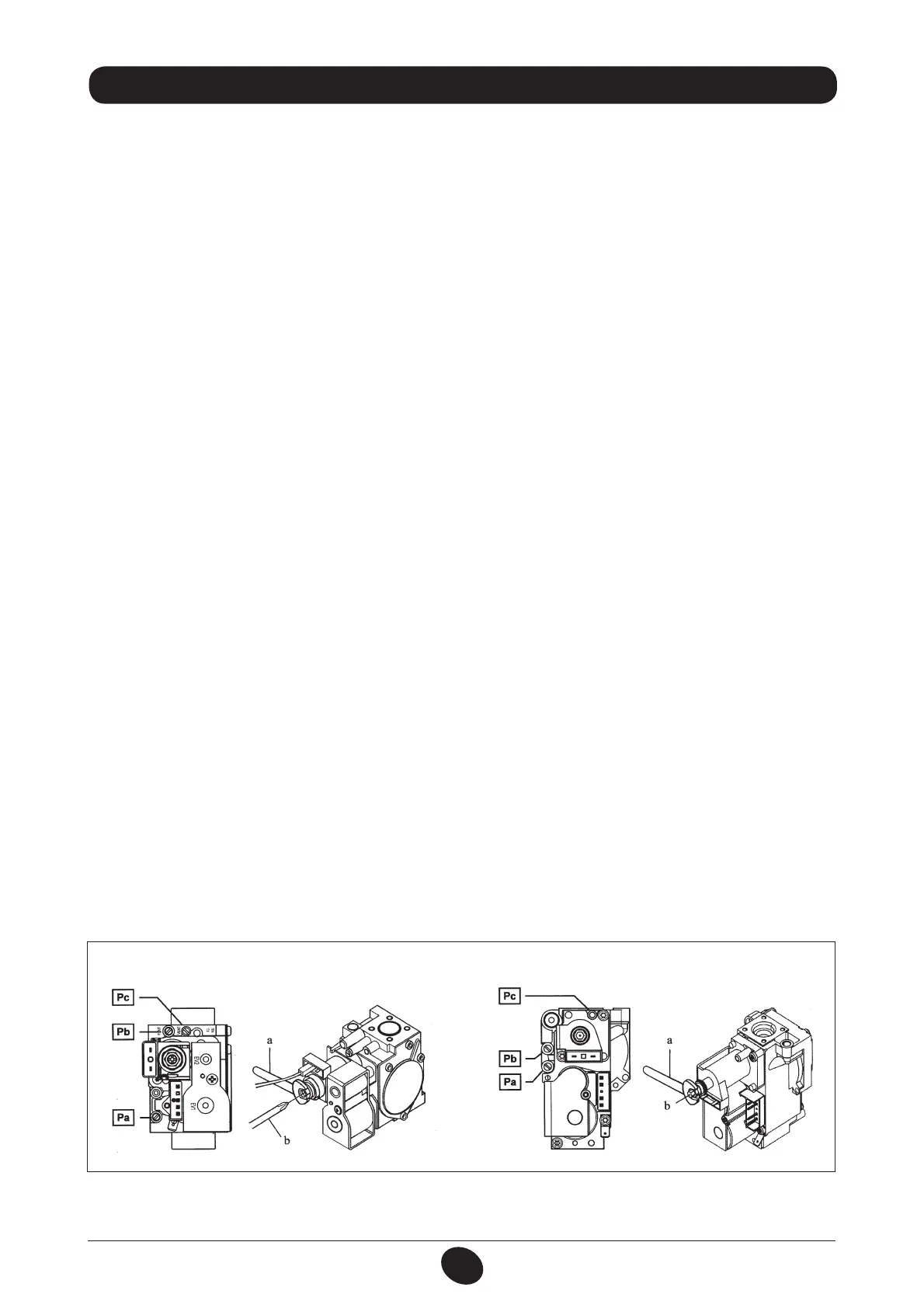

The procedure for calibrating the pressure regulator varies slightly according to the type of gas valve tted (HONEYWELL

or SIT, see gure 10).

Carry out the following operations:

A) replace the main burner nozzles;

B) change the modulator voltage

C) new max. and min. calibration of the pressure regulator.

A) Replace the burner injectors

• carefully pull the main burner off its seat;

• replace the main burner injectors making sure to fully tighten them to prevent gas leaks. Injector diameters are specied

in table 2.

B) Change the modulator voltage

• set parameter F02 according to the gas used, as described in section 21;

C) Calibrate the pressure regulator

• connect the positive pressure test point of a differential pressure gauge (possibly water-operated) to the gas valve

pressure test point (Pb) (Figure 10). Only for models with sealed chambers, connect the negative pressure test point

of the pressure gauge to a “T” tting in order to join the boiler adjustment outlet, the gas valve adjustment outlet (Pc)

and the pressure gauge. (The same measurement can be made by connecting the pressure gauge to the pressure test

point (Pb) after removing the front panel of the sealed chamber). Measuring burner pressure using methods other than

those described could lead to incorrect results as the low pressure created by the fan in the sealed chamber would not

be taken into account.

C1) Adjustment to nominal heat output:

• open the gas tap and switch the boiler to the Winter mode;

• open a hot water tap that can provide a ow rate of at least 10 litres a minute or make sure there is maximum heat

demand;

• remove the modulator cover;

• adjust the brass screw (a) until the pressure values shown in table 1 are obtained;

• make sure that the dynamic inlet pressure of the boiler, measured at the gas valve pressure test point (Pa) (Figure 10)

is correct (37 mbar for propane or 20 mbar for natural gas).

C2) Adjustment to reduced heat output:

• disconnect the modulator power cable and unscrew the screw (b) until a pressure value corresponding to reduced heat

output is achieved (see tab. 1);

• reconnect the wire;

• mount the modulator cover and seal.

C3) Final checks

• attach the additional plate supplied with the transformer specifying the type of gas and the calibration performed.

Figure 10

SIT valve - mod. SIGMA 845 Honeywell valve - mod. VK 4105 M

0904_0701

Loading...

Loading...