Common applications of KBR boilers

Greenstar FS/Combi FS – 6 720 810 590 (2020/04)

28

5 Common applications of KBR boilers

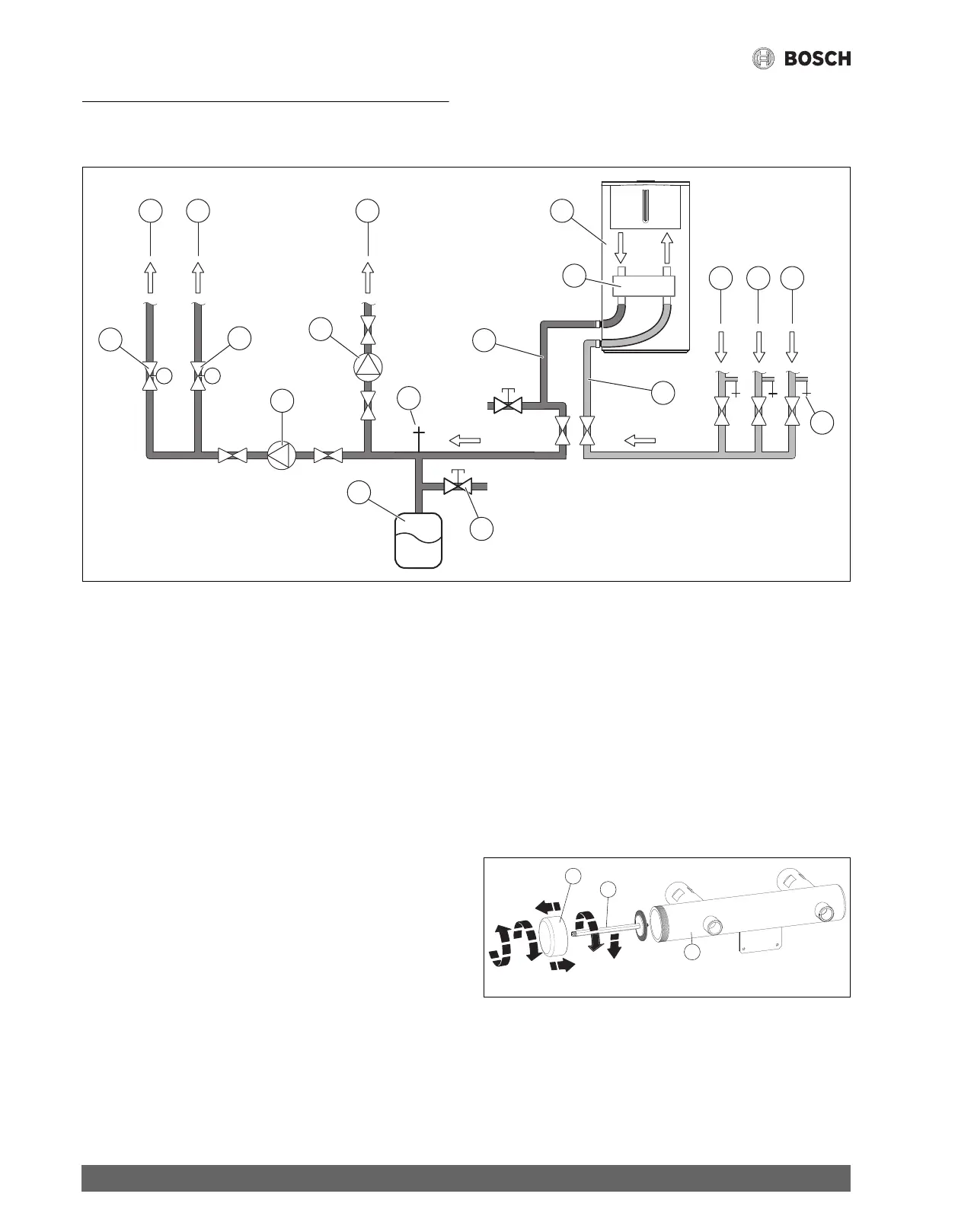

5.1 Multiple zones using zone valves with DHW

Fig. 10 Piping

[1] Supply to heating zone 2

[2] Motorized valve heating zone 2

[3] Supply to heating zone 1

[4] Motorized valve heating zone 1

[5] System pump

[6] DHW pump

[7] Supply to indirect tank

[8] Drain/Bleed point

[9] Boiler supply pipe 1¼ "

[10] Low Loss Header

[11] Heat only boiler

[12] Boiler return pipe 1¼ "

[13] Return from indirect tank

[14] Return from heating zone 1

[15] Return from heating zone 2

[16] Drain/Bleed point

[17] Combination fast fill/back flow preventer

[18] Expansion (tank) vessel

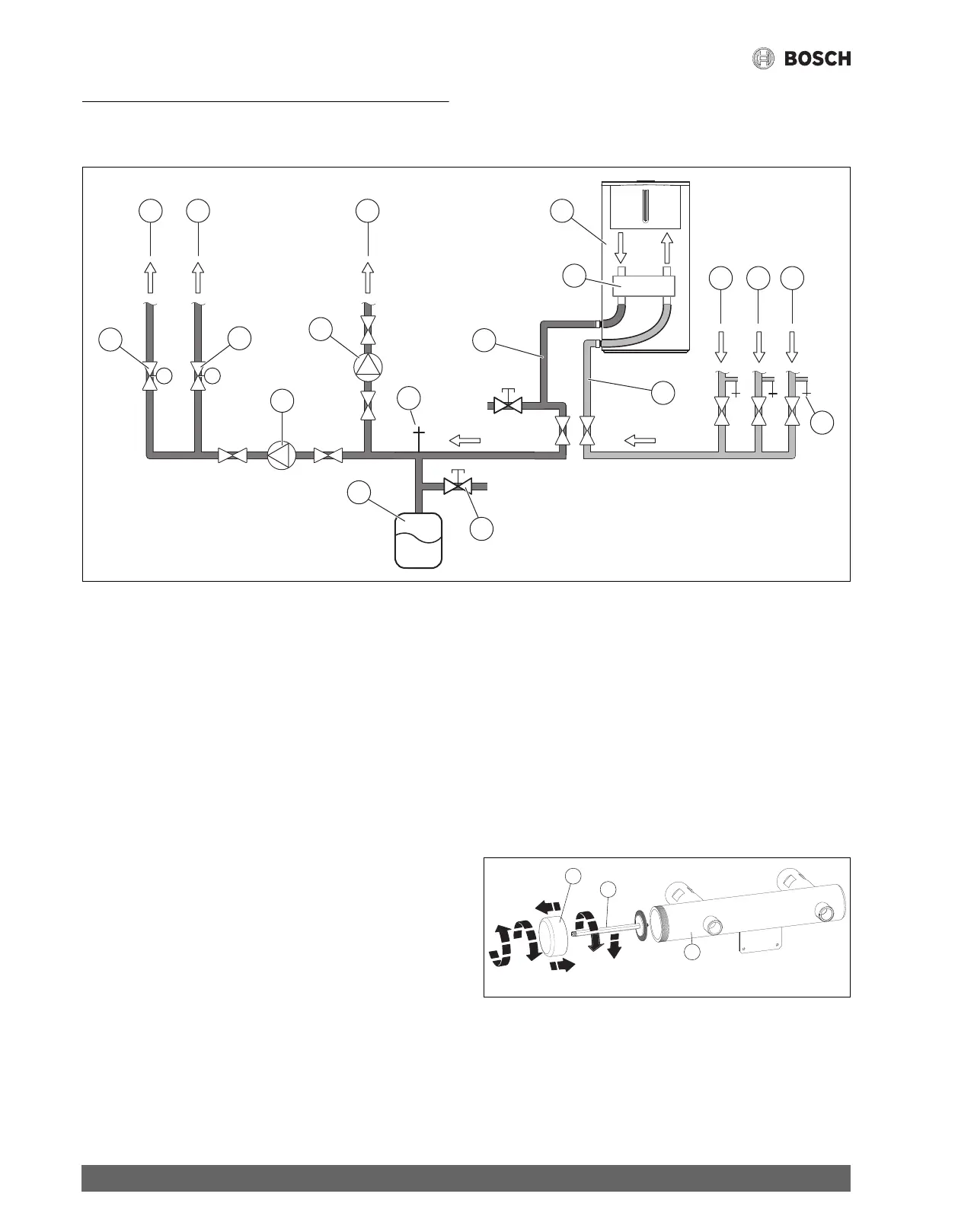

5.1.1 Utilizing the LLH

▶ Switch off and isolate the boiler

▶ Drain the boiler

▶ Remove front panel

▶ Locate the LLH at the left-hand side of the lower section of the boiler

1. Unscrew the cap [a] from the body of the LLH [c]

– This will break the label across the cap and body indicating that

the LLH has been employed

2. Withdraw the cap [a] and plunger assembly [b]

3. Unscrew the plunger assembly [b] from the cap [a],

4. Set the plunger assembly [b] aside

5. Re-fit the cap [a] without the plunger assembly [b]

6. Tighten the cap [a] and ensure it is secure.

Fig. 11 Utilizing the LLH

6720810590-15.1Wo

MM

1 3 7

2

4

6

5

18

9

17

8

12

13 14 15

11

10

16

c

a

b

2.

4.

1.

5.

6.

6720811590-37.1Wo

3.

Loading...

Loading...