Inspection and maintenance

Greenstar FS/Combi FS – 6 720 810 590 (2020/04)

72

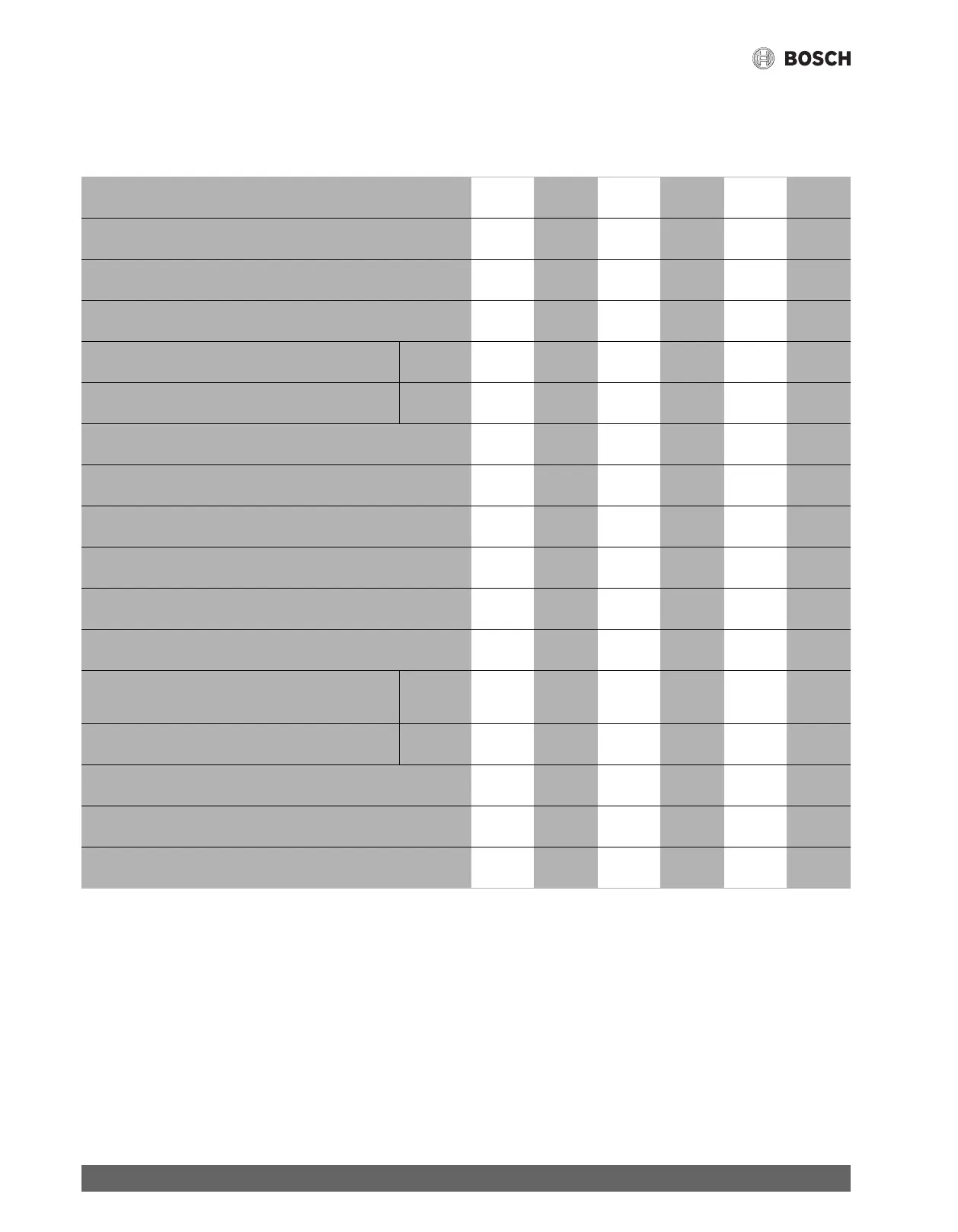

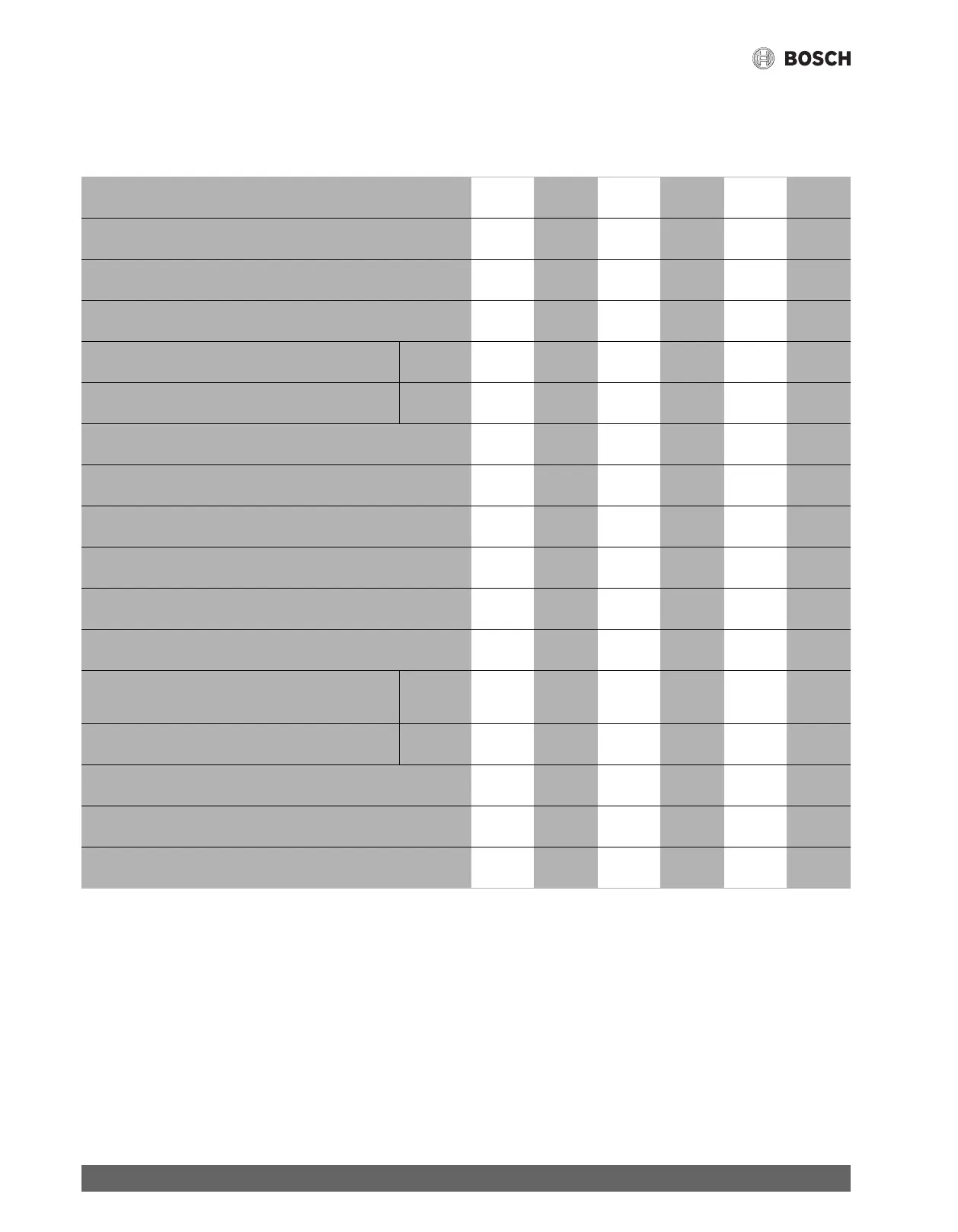

15.2 Checklist for annual inspection and maintenance

▶ Use this form to guide you through the service and maintenance

procedure. Fill out each step according to the findings and work

performed.

Table 37 Maintenance and inspection checklist

Date

1 Latest fault code from service function 6.A ( Section 15.1.1).

2 Fresh water inlet filter (Combi boiler KWB appliances only)

( Section 15.1.2).

3 Visual inspection of the combustion air pipes and vent pipes.

4 Dynamic gas pressure (Section 12.3). inches W.C.

(mbar)

5 Gas-air ratio at min./max. nominal output

( table 77).

min. %

max %

6 Gas and water-side leak test ( Section 6.10).

7 Inspect electrodes ( Section 15.1.4).

8 Inspect heat exchanger block ( Section 15.1.6).

9 Check burner ( Section 15.1.5).

10 Inspect diaphragm in mixer unit ( Section 15.1.8).

11 Clean condensate trap (Section 15.1.7).

12 With the system depressurized, check the expansion

vessel pre-charge pressure vs. the static head of the

heating system.

psi (bar)

13 Check the heating system filling pressure. psi (bar)

14 Inspect electrical wiring for damage.

15 Check settings of the heating control.

16 Check set service functions according to commissioning report

( Chapter 18).

Loading...

Loading...