26/64 Axial piston units | Transport and storage

Bosch Rexroth AG, RE90300-B/2021-01-19

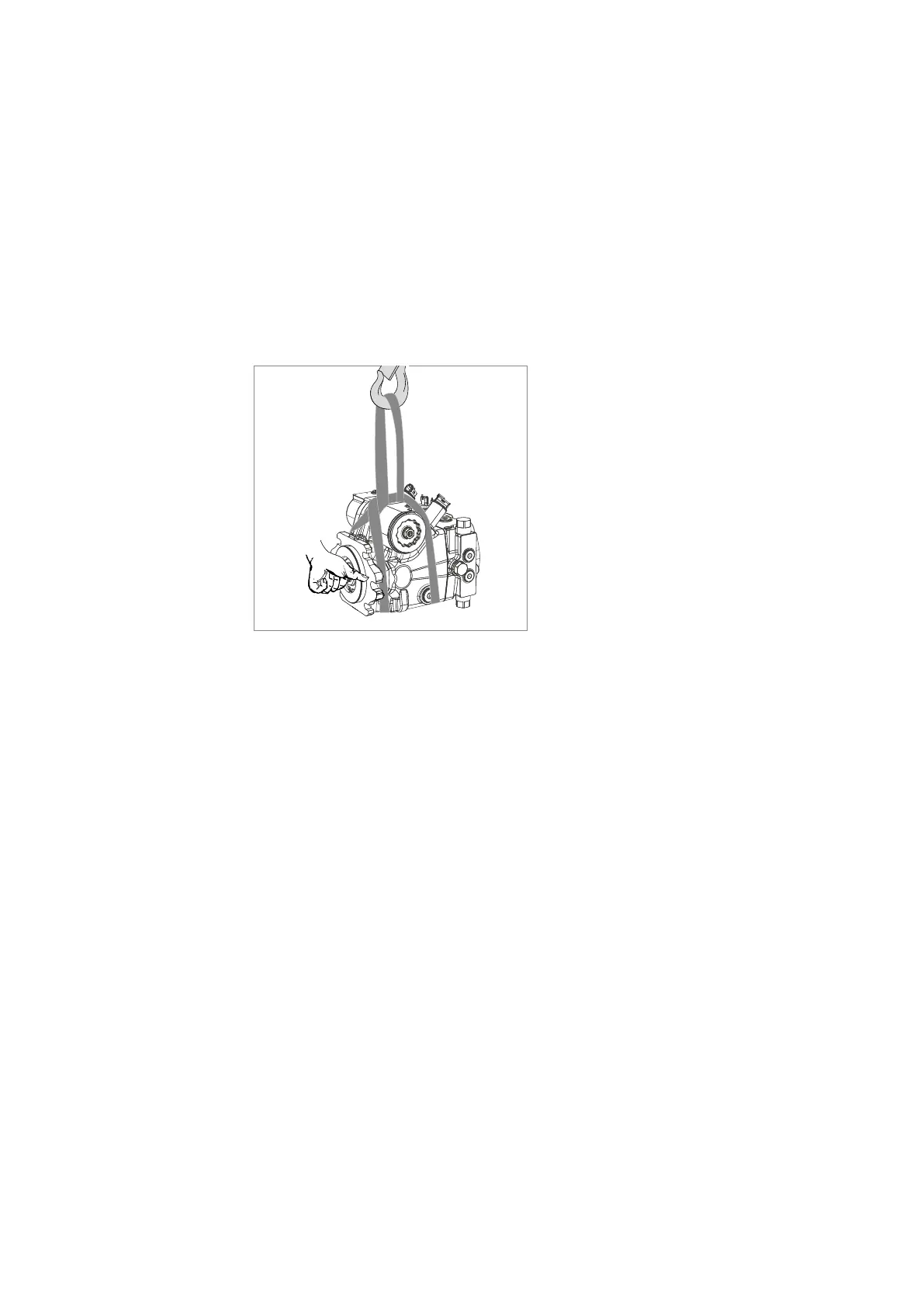

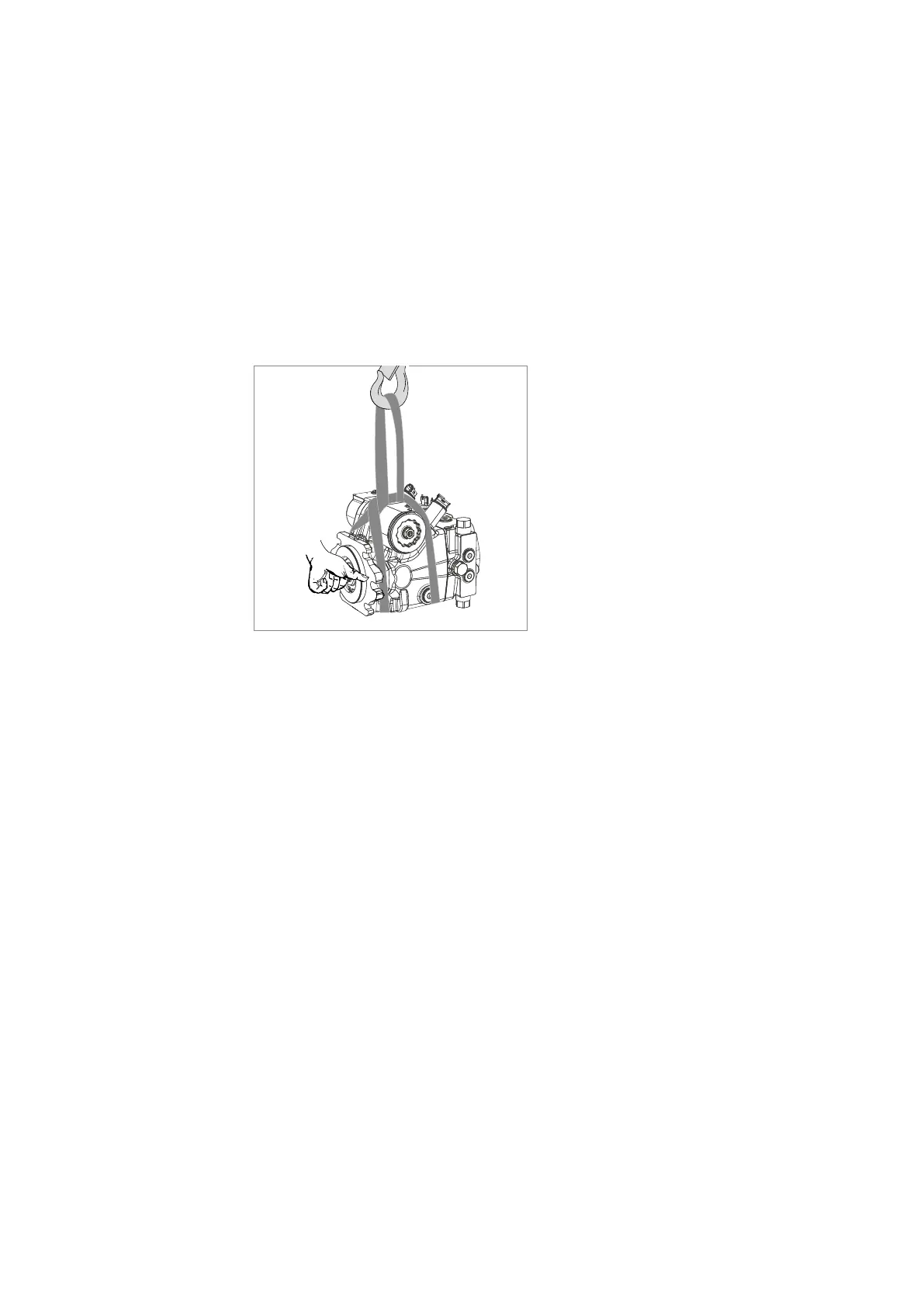

WARNING! Danger due to suspended loads!

During transport with lifting strap, the axial piston unit can topple out of the lifting

strap and cause injury.

▶ Use the widest possible lifting strap.

▶ Make sure that the axial piston unit is securely fixed with the lifting strap.

▶ Only guide the axial piston unit by hand for fine positioning and to avoid swinging.

▶ Never step or grip under suspended loads.

▶ Place the lifting strap around the axial piston unit in such away that it does not

pass over assembled parts (e.g.valves, piping) and that the axial piston unit is

not suspended from assembled parts (see Fig. 4).

Fig. 4: Transport with lifting strap

6.2 Storing the axial piston unit

• Storage areas should be free of corrosive materials and gases.

• To prevent damage to the seals, do not operate ozone-forming equipment

(e.g.mercury-vapor lamps, high-voltage equipment, electric motors, sources of

electrical sparks or electrical discharge) in storage areas.

• Storage areas should be dry.

Recommended relative humidity ≤ 60%.

• Ideal bearing temperature: +5°C to +20°C.

• Minimum storage temperature: -50 °C (exception: units with on-board electronics).

• Maximum storage temperature: +60°C.

• Keep out of direct sunlight.

• Do not stack axial piston units and store them in ashock-proof manner.

• Do not store the axial piston unit on the drive shaft or assembled parts,

e.g.sensors or valves.

• For further storage conditions, see Table 6.

▶ Check the axial piston unit monthly to ensure professional storage.

Transport with lifting strap

Requirement

Loading...

Loading...