Commissioning

51

Greenstar – 6721822579 (2021/01)

8.1 Before operating the appliance

NOTICE

Commissioning without being properly filled and purged will

damage the appliance.

▶ Only operate this appliance after ensuring there is sufficient water in

the boiler and the system.

▶ Adjust the expansion vessel pre-charge pressure to the static head of

the heating system ( page 31).

▶ Open radiator and zone valves (as applicable).

▶ Open heating supply and return valves, fill heating system to 14.5 to

21.75 psi (1 - 1.5 bar) and close fill valve.

▶ Bleed all air from the system.

▶ If the boiler water pressure has dropped, fill the heating system again

to 14.5 to 21.75 psi (1 to 1.5 bar).

▶ On ZBR...-3A appliances (heating boilers) with a DHW tank, open the

cold water supply and open a DHW tap until water runs out.

▶ Verify that the gas type specified on the rating plate is the same as the

gas type used.

▶Open the gas cock.

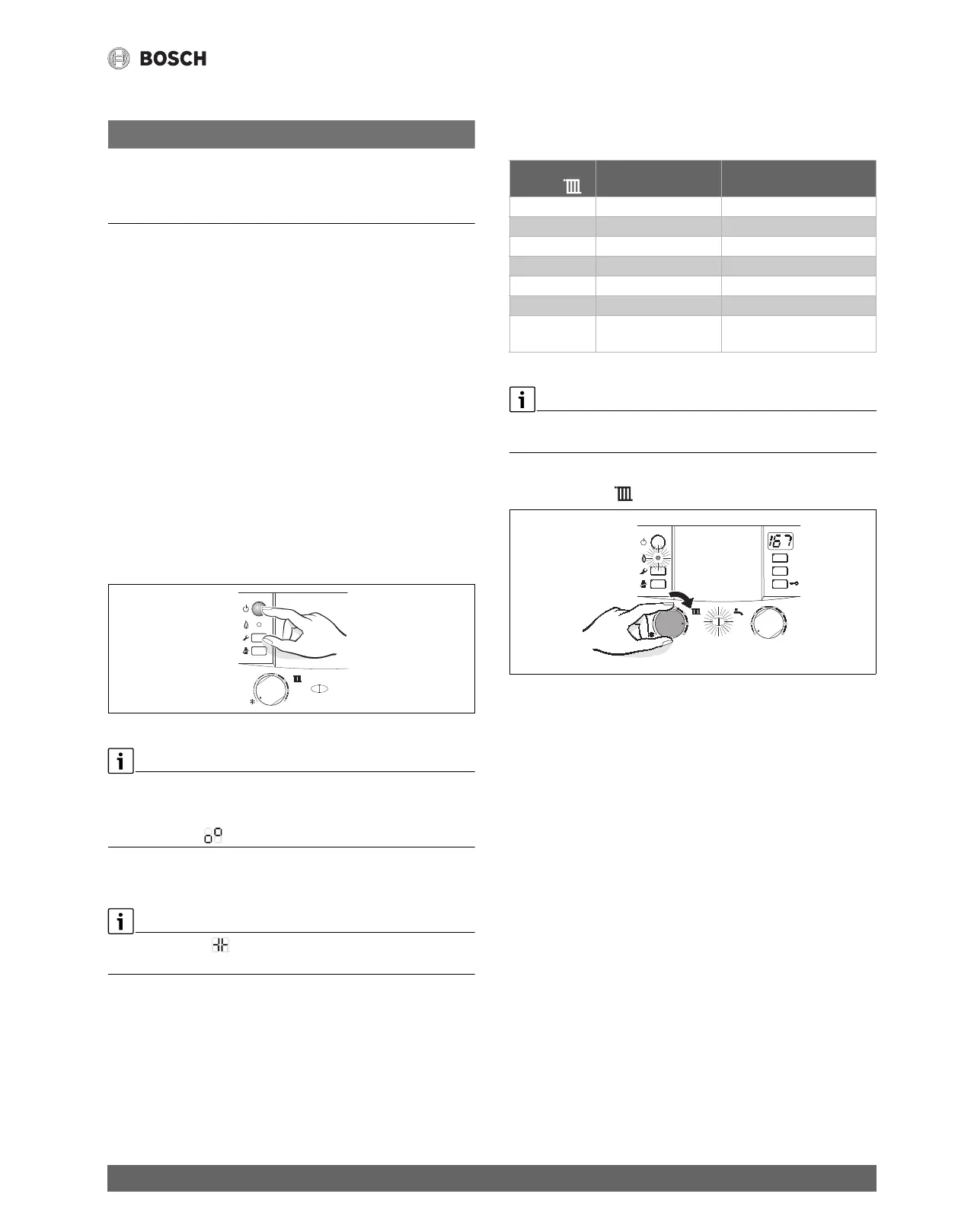

8.2 Switching the appliance ON/OFF

Startup

▶ Switch the appliance ON using the ON/OFF switch.

The display indicates the supply temperature of the hot water in °F. If

necessary, convert to °C ( page 60).

Fig. 63 Switching the appliance ON/OFF

When the appliance is switched ON for the first time, it performs a once-

only purging sequence. This involves the heating zone pump switching

on and off at intervals (for approx. 4 minutes).

The display shows in alternation with the supply temperature.

▶ Open the automatic vent [9] (only ZWB...-3A) and close it again

when the purging sequence has finished ( page 50).

If the display shows in alternation with the supply temperature, the

trap filling function is active ( page 59).

Shutdown

▶ Switch appliance OFF using the ON/OFF switch.

The display goes out.

▶ If the appliance is taken out of service for a longer period: Observe

frost protection ( Section 8.9).

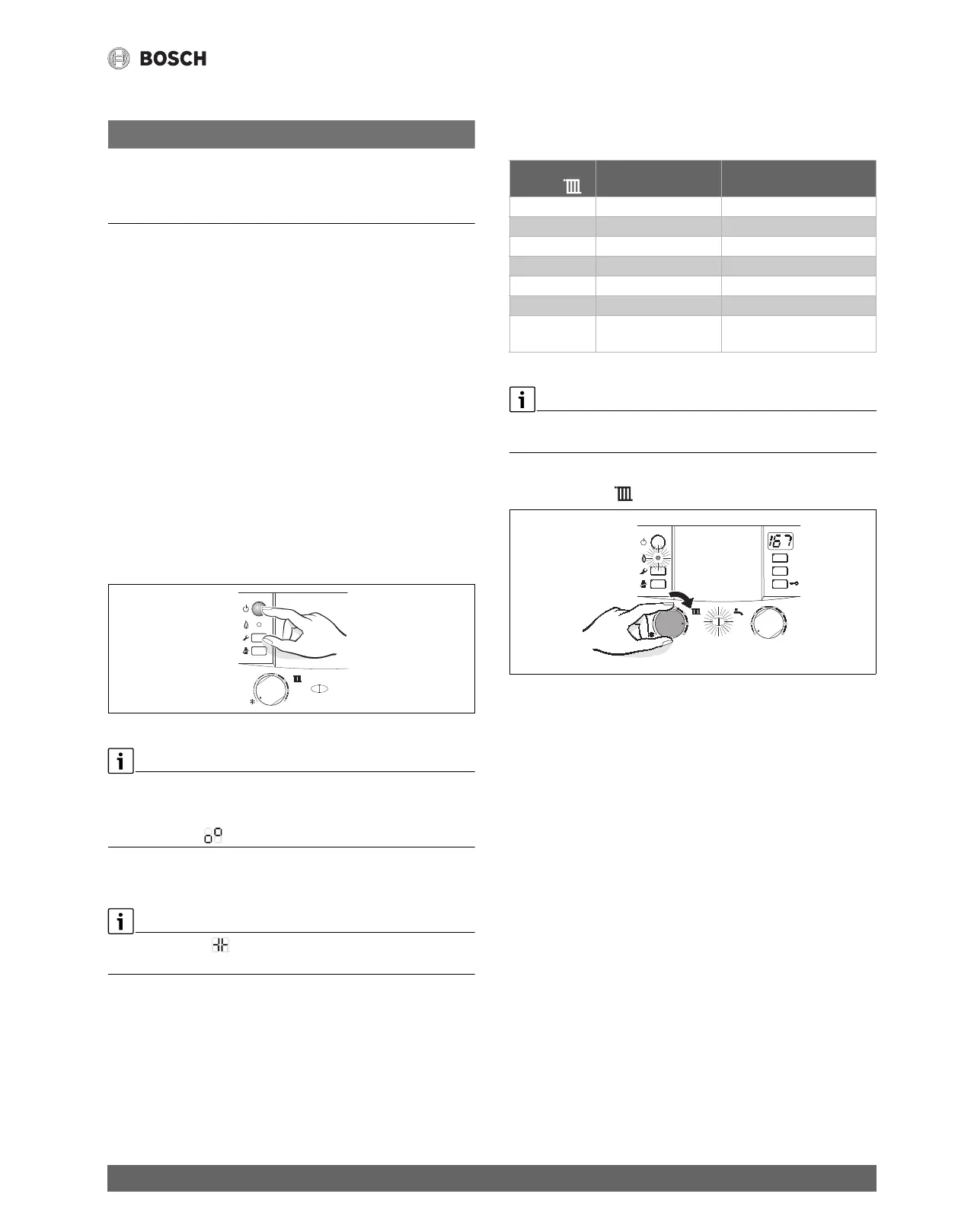

8.3 Switch on heat

Set the maximum supply temperature based on the structure's heat loss

on design day.

Table 22 Typical supply temperatures

With radiant floor heating, limit the maximum permissible supply

temperature as recommended by the manufacturer.

▶ In order to set the maximum supply temperature, turn the supply

temperature dial knob.

Fig. 64 Switch on heat

If the burner is operating, the burner operation indicator lamp is

illuminated.

m

a

x

1

2

3

4

5

6

6 720 613 896-05.1O

Boiler high

limit dial

Typical supply

temperatures

Sample application

1 approx. 95 °F (35 °C) Frost protection

2 approx. 109 °F (43 °C)

3 approx. 122 °F (50 °C) Radiant floor heating system

4 approx. 140 °F (60 °C) Panel radiator system

5 approx. 153 °F (67 °C) Cast iron radiator system

6 approx. 167 °F (75 °C)

max approx. 187 °F (86 °C) Baseboard and convector

system

eco

reset

6 720 641 933-53.2O

max

1

2

3

4

5

6

max

1

2

3

4

e

6

min

Loading...

Loading...