Notes on installation and operation

Greenstar – 6721822579 (2021/01)

30

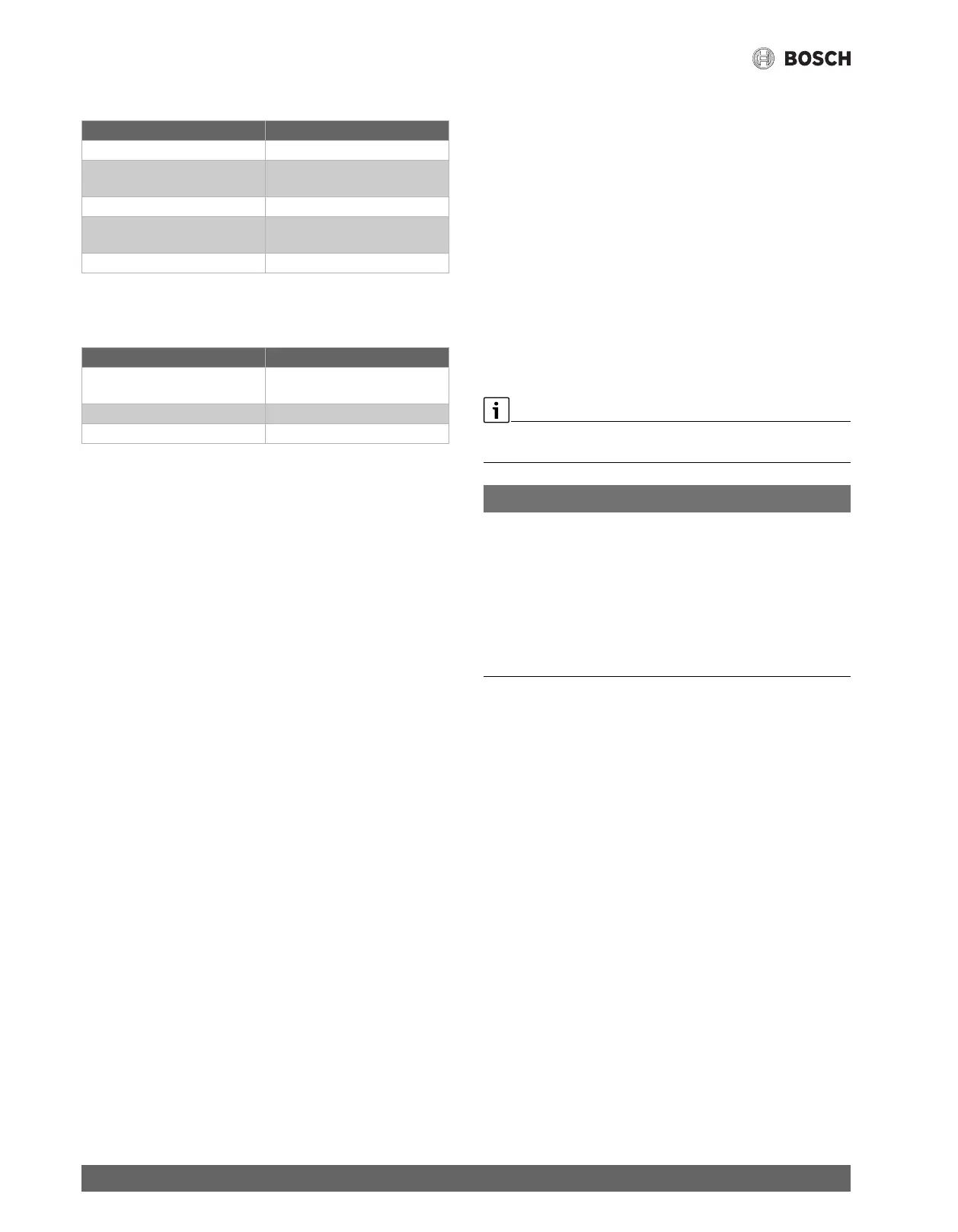

The following anti-freeze fluids and concentrations have been approved:

Table 11 Anti-freeze

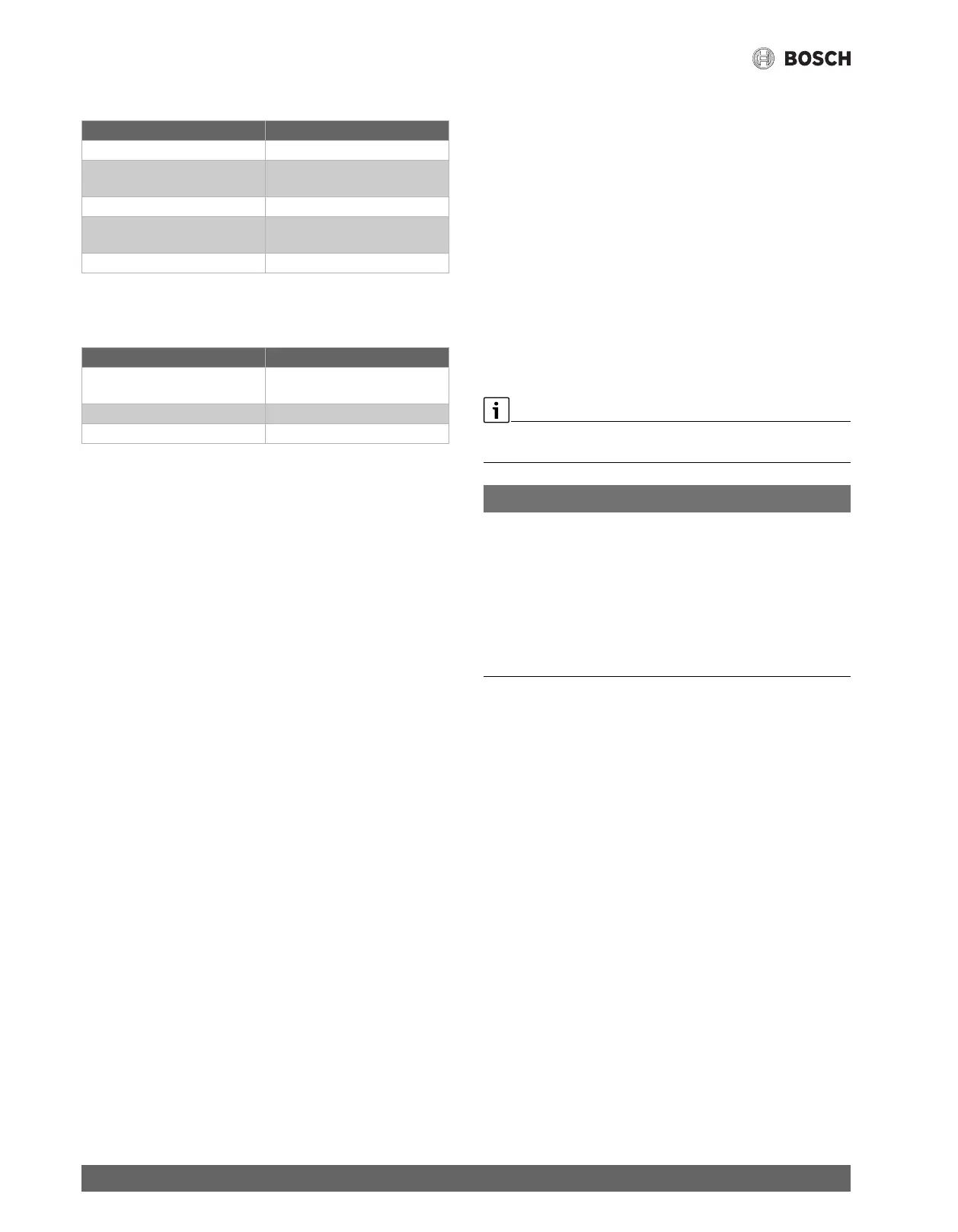

Corrosion inhibitors

The following anti-corrosion agents are approved:

Table 12 Corrosion inhibitors

▶ System fluid pH must be maintained between 7 and 8.5 to prevent

system damage.

▶ Use only untreated water to fill the system.

▶ Do not use TSP (tri-sodium phosphate).

▶ Do not use fill water treated with salt bedding type exchangers (ion

exchanger).

▶ Never introduce non-approved boiler treatment or similar additives.

▶ Only use fill water with a hardness below 7 grains.

▶ Filling with chlorinated water is acceptable if chlorine levels are

below 100 ppm.

▶ Do not use inhibitors or other additives unless listed in this

document.

▶ Consult a local water treatment specialist for recommendations if any

of the above is outside the stated ranges.

▶ When using oxygen permeable PEX, the system must be separated

from the boiler by a heat exchanger.

▶ A correctly sized and working expansion vessel must be installed.

▶ Do not exceed the maximum permissible fl ow rate through the boiler.

Excessive flow can cause erosion damage to the heat exchanger.

▶ Eliminate leaks in the system

Continually topping up the system constantly adds oxygen to the

heating water, causing corrosion damage. All system leaks must be

repaired.

Boiler sealer

This boiler is not approved for use with boiler sealer.

LPG

To protect the appliance against high pressure (ANSI/Z223.1/NFPA54

(National fuel gas code) or CAN/CSA B 149.1 (Natural Gas and Propane

installation code)):

▶ Install a pressure regulator with a safety valve.

6.1.2 Other important information

• The installation of this boiler must comply with all national and local

code and regulations.

• Only operate this boiler with the combined air/flue system

specifically designed and approved for it.

• Use only approved venting systems per the manufacturer's

instructions.

• Do not dispose of untreated boiler condensate in septic systems.

• Inspect the sewer pipes for suitability before disposing of untreated

boiler condensate in them.

• Verify with the local authority that disposing of untreated boiler

condensate into public sewer systems is permitted.

6.1.3 Water Supply Pressure

The connection pressure of the water supply must be between 4.35 psi

and 150 psi.

▶ If necessary, install a pressure reducing valve.

For optimum performance it is recommended to keep pressure between

20 to 30 psi.

NOTICE

Damage due to overpressure.

Non-return, backflow prevention devices (including those associated

with water meters) fitted to the incoming water supply can cause a

pressure build up which could damage the boiler and other household

appliances.

▶ Where the incoming water supply has a non-return, backflow

prevention vavle installed, a mini expansion vessel should be

connected to the water supply pipe between the non-return valve and

the boiler.

Chemical Name Concentration

Nalco (Varidos) FSK 22 - 55 %

Fernox Alphi 11 Observe manufacturer's

instructions

Intercool NFP-50 AA 0 - 39 %

Antifrogen N Observe manufacturer's

instructions

NoBurst AL 0 - 55 %

Chemical Name Concentration

Fernox F1 Observe manufacturer's

instructions

Nalco 77381 1 - 2 %

Sentinel X 100 1.1 %

Loading...

Loading...