Regulations

23

Greenstar – 6721822579 (2021/01)

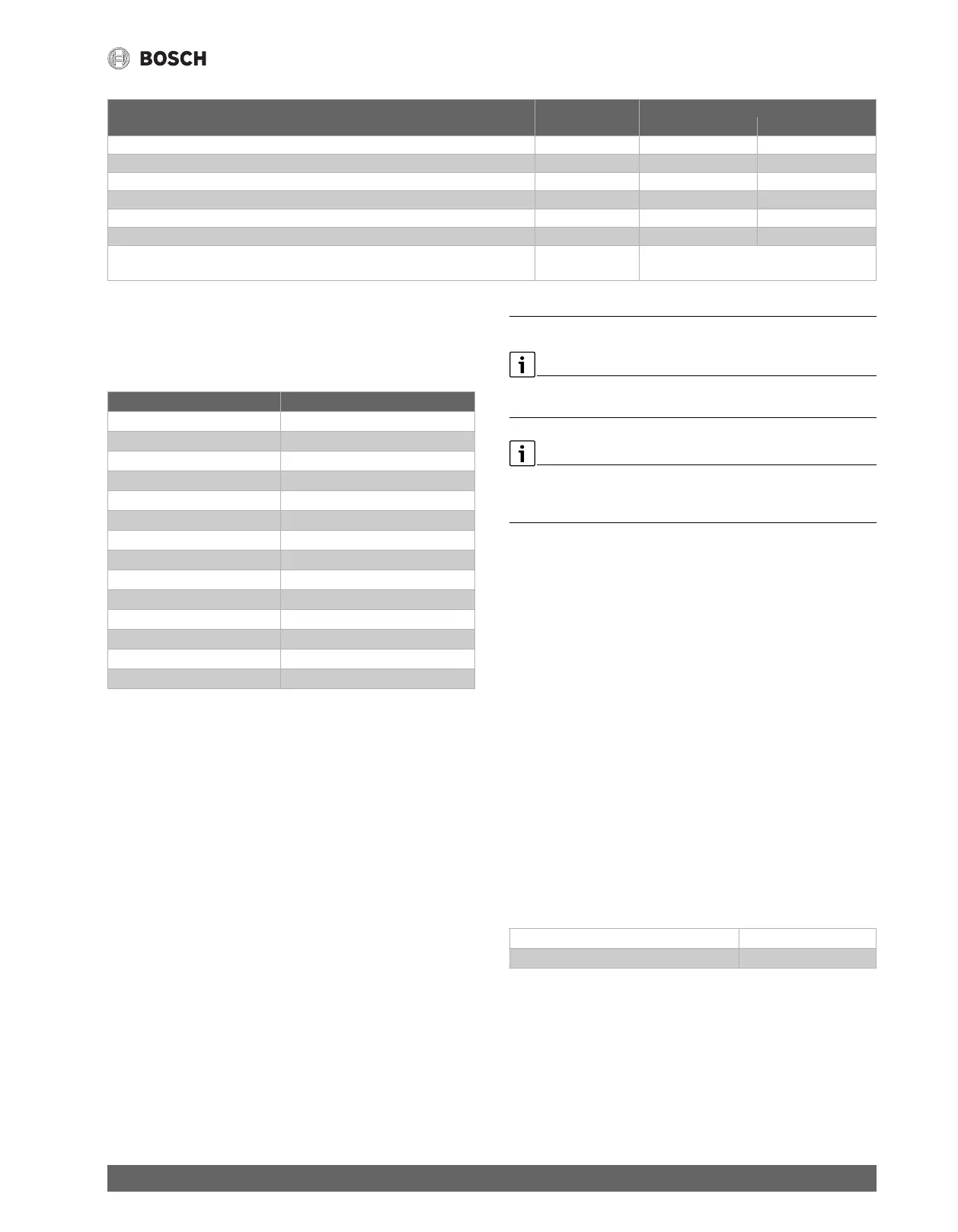

Table 7 Technical data ZWB42-3A...

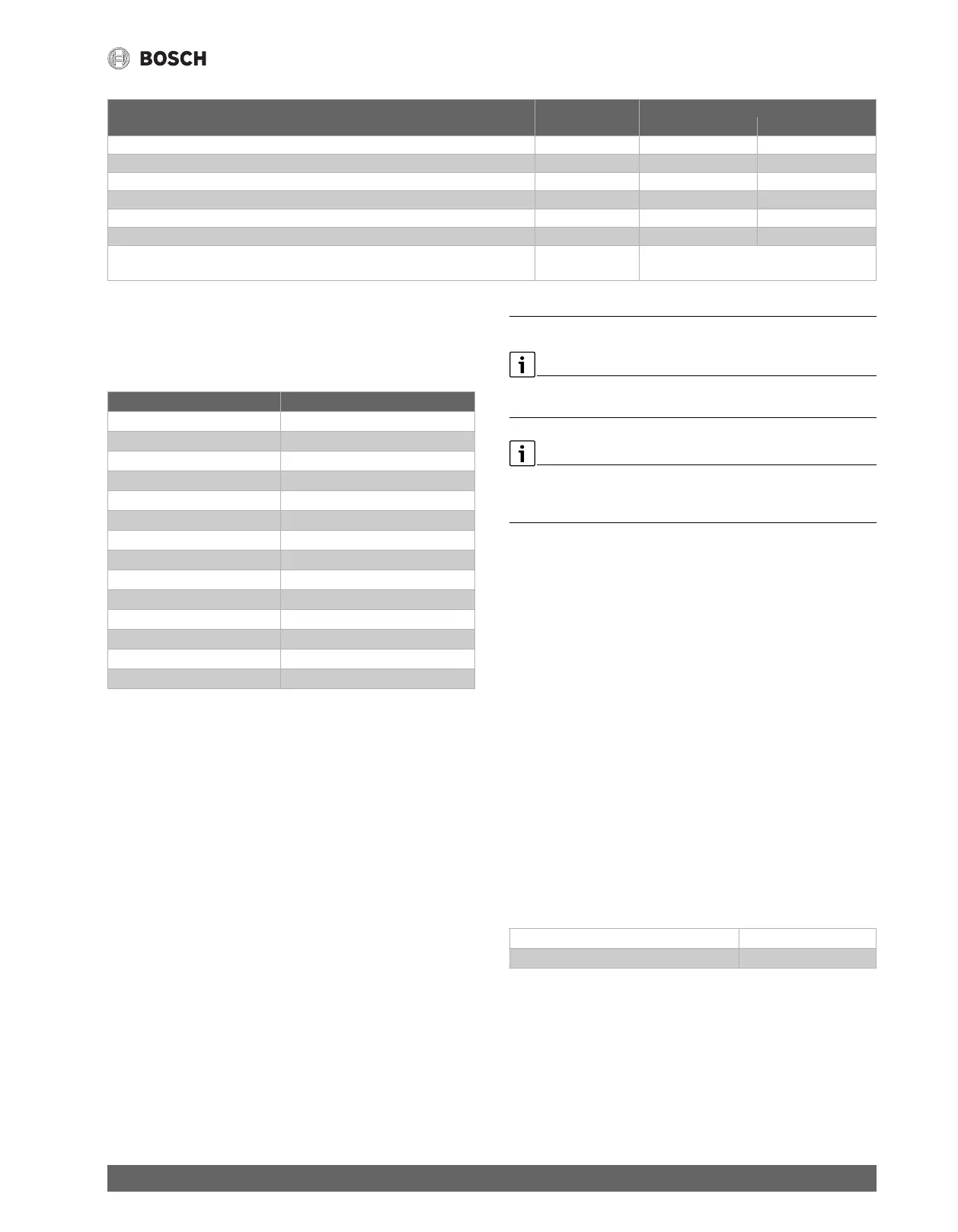

3.13 Condensate composition

The condensate volume and ingredients may change with regionally and

seasonally varying gas quality and air quality. Typically the following

ingredients and concentrations can be expected:

Table 8 Typical condensate composition

4Regulations

Observe all rules, regulations, standards and guidelines applicable to the

installation and operation of this appliance in your country.

Valves external to the boiler must be fitted with T-handles and

condensate piping must be installed in accordance with the State

Plumbing Code.

4.1 Compliance with standards and regulations

The installation must conform to the requirements of the authority

having jurisdiction or, in the absence of such requirements, to the latest

edition of the National Fuel Gas Code, ANSI Z223.1./NFPA 54. In

Canada, installation must be in accordance with the requirements of

CAN/CSA B149.1, Natural Gas and Propane Installation Code.

This wall-mounted condensing gas boiler complies in its design and

mode of operation with the American National Standard ANSI Z21.13/

CSA4.9, latest edition for Gas-Fired Low-Pressure Steam and Hot Water

Boilers.

Other confirmed approvals and certifications are indicated by labels on

the boiler.

If so advised by the responsible agency, the installation must satisfy the

requirements of the standard for Controls and Safety Devices for.

Automatically Fired Boilers, ANSI/ASME CSD-1.

Install CO detectors per local regulations. Wall-mounted gas condensing

boilers require yearly maintenance ( Chapter 15, page 65).

4.2 Operating limits of the boiler

The heat exchanger has been designed and certified in accordance with

the ASME Boiler and Pressure Vessel Code, Section IV.

Table 9 Operating limits

The hot water distribution system must comply with all applicable codes

and regulations. When replacing an existing boiler, it is important to

check the condition of the entire hot water distribution system to ensure

safe operation.

Common practice calls for inspecting an existing system in its entirety

and bringing it up to code. All pipework should be properly cleaned and

flushed.

Sound pressure level dB(A) ≤ 45 ≤ 45

Max. supply temperature °F ( °C) 187 (86) 187 (86)

Max. permissible operating pressure (P

MS

) heating psi (bar) 30 (2.07) 30 (2.07)

Permissible ambient temperature °F ( °C) 32 - 122 (0 - 50) 32 - 122 (0 - 50)

Nominal water capacity (heating) gal (l) 0.925 (3.5) 0.925 (3.5)

Weight (without packaging) lbs. (kg) 110.2 (50) 110.2 (50)

Dimensions, W x H x D inch

(mm)

17-21/64" × 33-15/32"13-57/64"

(440 × 850 × 353)

ZWB 42-3 A...

Input/Output at elevation 0 - 2000 feet (0 - 610 m) Unit NG LPG (propane)

Substance Value in ppm (mg/l)

Ammonium 1.2

Lead ≤0.01

Cadmium ≤ 0.001

Chrome ≤0.005

Halogenated hydrocarbons ≤ 0.002

Hydrocarbons 0.015

Copper 0.028

Nickel ≤0.1

Mercury ≤ 0.0001

Sulfate 1

Zinc ≤ 0.015

Tin ≤0.01

Vanadium ≤ 0.001

pH-value 4.8

Maximum boiler temperature 187 °F (86 °C)

Maximum operating pressure 30 psi (2.07 bar)

Loading...

Loading...