In the USA and Canada, a 24 hour hot line, 1-800-233-3723, has a menu of pre-recorded messages offering you engine maintenance information.

7

Maintenance

See Maintenance Schedule, page 8. Follow the hourly or calendar intervals, whichever occur first.

Note that more frequent service is required when operating in adverse conditions.

Keep engine and parts clean.

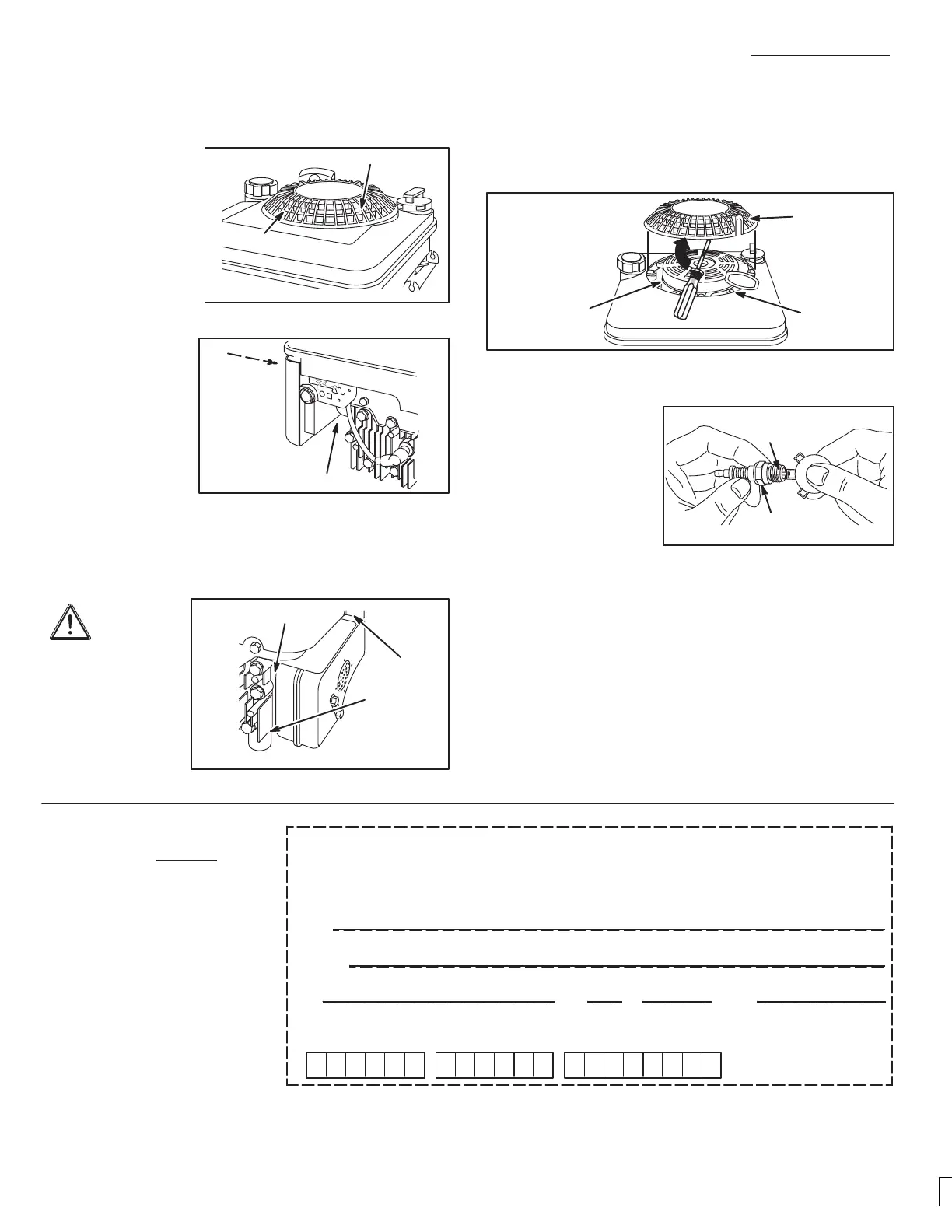

Do not clean with a forceful spray of water because water

could contaminate fuel system.

With a brush or cloth,

remove grass, chaff or

debris from finger

guard daily (more often

if needed) to prevent

engine damage caused

by overheating.

Finger guard

CLEAN

CLEAN

Linkage, springs & controls

To assure smooth op-

eration, keep governor

linkage, springs and

controls free of debris.

CLEAN

CLEAN

If engine muffler is equipped with spark arrester screen,

remove for cleaning and inspection. Replace if damaged or

plugged. See an Authorized Briggs & Stratton Service Dealer

for correct replacement.

Muffler area/Spark arrester

Daily or more often,

before running engine,

clean muffler area to

remove all grass and

combustible debris.

CLEAN

CLEAN

CLEAN

Grass, chaff or debris may clog the air cooling system, espe-

cially after prolonged operation cutting tall, dry grass. Internal

cooling fins and surfaces may require cleaning to prevent

overheating and engine damage. To obtain service, contact

any Briggs & Stratton Authorized Service Dealer.

Air cooling system

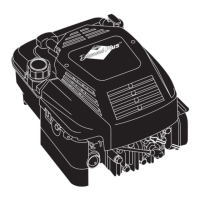

CLEAN

PRY OFF

FINGER

GUARD

CLEAN

.030” (0.76 mm)

WIRE GAGE

RESISTOR P/N 802592

STANDARD P/N 492167

Spark plug

Use only Briggs & Strat-

ton Spark Tester, Part No.

19368, to check for spark.

Replace or clean spark

plug. Do not blast clean.

Clean by scraping or wire

brushing and washing

with a commercial solvent.

Note: In some areas, local law requires using resistor spark plug

to suppress ignition signals. If this engine was originally equipped

with resistor spark plug, use same type for replacement.

Remove combustion deposits.

Remove cylinder head every 100-300 hours of operation.

Scrape and wire brush combustion deposits from cylinder,

cylinder head, top of piston and around valves. Use a soft

brush to remove deposits. Reassemble gasket and cylinder

head. Turn screws down finger tight. Torque cylinder head

screws in a staggered sequence to 140 in.-lbs. (15.8 Nm).

273693

Fill in both sides, clip and return to:

Briggs & Stratton Corporation

P.O. Box 1144

Milwaukee, WI 53201-1144 U.S.A.

Your Engine

Type

Code

Model

See any Authorized Briggs & Stratton

Service Dealer. Insist on Genuine

Briggs & Stratton parts! Non-original

parts may not perform as well and

may void your warranty.

To obtain a complete Parts List of

Genuine Briggs & Stratton Parts for

your engine, fill in both sides of this

order form carefully. We cannot fill

your order without the correct

Engine Model/Type/Code. (Please

allow 3 to 4 weeks for delivery.)

Loading...

Loading...