In the USA and Canada, a 24 hour hot line, 1-800-233-3723, has a menu of pre-recorded messages offering you engine maintenance information.

6

Maintenance

See Maintenance Schedule, page 8. Follow the hourly or calendar intervals, whichever occur first.

Note that more frequent service is required when operating in adverse conditions.

To prevent accidental starting,

remove spark plug wire from spark

plug and disconnect battery at nega-

tive terminal, if equipped, when

servicing engine or equipment.

WIRE

TAB

Oil

Check oil level regularly.

Be sure correct oil level is maintained. Check every 5 hours or

daily, before starting engine. See check oil level on page 3.

Change oil (Follow Maintenance Schedule.)

Change oil after first 5 hours of operation. Change oil while

engine is warm. Preferably drain oil from top of engine as illus-

trated below. Drain oil with air cleaner side up. Oil can be

drained from engine bottom if necessary.

Top oil drain

Before tipping en-

gine or equip-

ment to drain oil,

drain fuel from

tank by running

engine until fuel

tank is empty.

AIR

CLEANER

Remove drain plug and drain oil. Replace drain plug. Remove

dipstick and refill with new oil of recommended grade (see chart

on page 3). Start and run engine at idle for 30 seconds. Stop

engine. Wait 30 seconds and re-check oil level. If required, add

oil to bring level to FULL mark on dipstick.

Typical

drain

plugs

Bottom oil drain

PIPE

3/8” SQUARE

OIL DRAIN

PLUG

Oil fill

Dual Element Air cleaner

Note: Depending on engine Type Number, this engine may

not be equipped with a pre-cleaner.

To service pre-cleaner, wash in liquid detergent and water.

Allow to dry thoroughly before using. Do not oil pre-cleaner.

Replace if very dirty or damaged.

To service cartridge, clean by tapping gently on a flat surface.

Do not oil cartridge. Replace if very dirty or damaged.

Note: Do not use petroleum solvents, e.g., kerosene, which will

cause the cartridge to deteriorate. Do not use pressurized air

to

clean cartridge. Pressurized air can damage the cartridge.

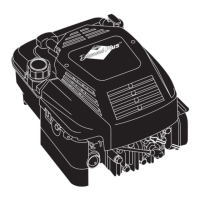

Square dual element

1. Loosen screw and tilt cover down. Carefully remove pre-

cleaner (if equipped) and cartridge assembly from cover.

2. After servicing pre-cleaner and cartridge, place pre-clean-

er, if equipped, over cartridge pleats with arrows in direc-

tion shown (pre-cleaner lip will be at bottom of pleats).

3. Install pre-cleaner and cartridge assembly in cover.

4. Insert tabs on cover into slots in bottom of base.

5. Tilt cover up and tighten screw securely to base.

Square dual element air cleaner

SCREW

COVER

BASE

PRE-CLEANER

P/N 493537

CARTRIDGE

P/N 491588

or P/N 5043

CARTRIDGE

LIP

ASSEMBLE SO CARTRIDGE LIP TOUCHES

BASE IN DIRECTION SHOWN

PRE-CLEANER LIP

TABS AND

SLOTS

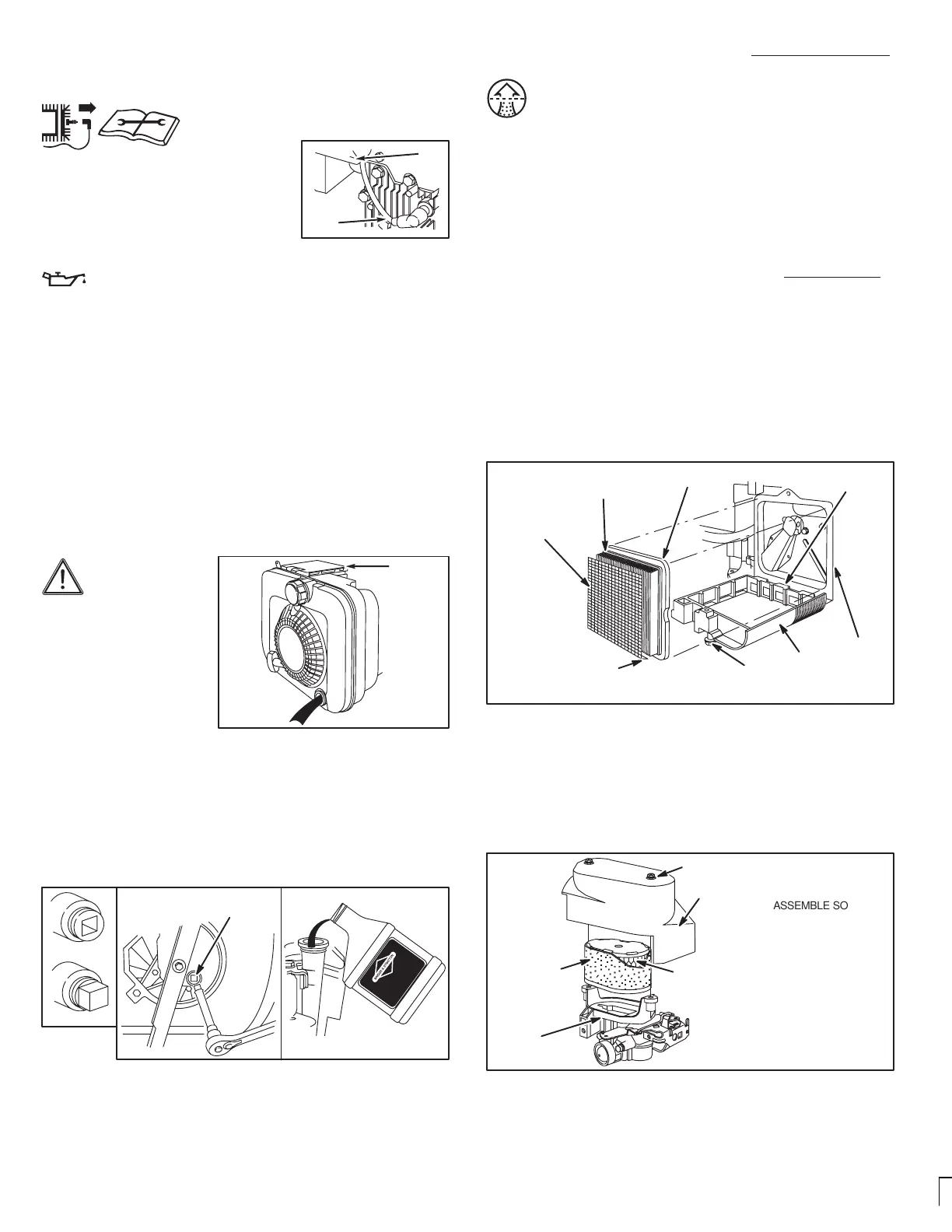

Oval dual element

1. Loosen screws and lift cover. Then carefully remove

pre-cleaner, if equipped, and cartridge assembly.

2. After servicing pre-cleaner and cartridge, place

pre-cleaner on cartridge.

3. Install air cleaner assembly in base. Then install cover on

air cleaner and tighten screws securely to base.

Oval dual element air cleaner

ASSEMBLE SO THAT

CARTRIDGE LIP

SITS INSIDE BASE

2 SCREWS

COVER

BASE

CARTRIDGE

P/N 497725

Loading...

Loading...