3

1.4 Vacuum Connections and Drip Legs

Use a line size to the vacuum system that is at least as

large as that of the pump inlet. Smaller lines will result

in lower pumping speeds than the rated values.

Install a drip leg and drain on the vertical pipe near the

pump inlet. Also, when installing discharge piping, a

drip leg should be installed. Drain the drip legs often to

remove any condensation which may have collected.

If more than one vacuum pump or a receiver tank is

connected to a common main line, each pump should

have its own manual or automatic operated shut-off

valve or positive action check valve. The built-in, anti-

suck-back valve should not be used as a shut-off valve

for the vacuum system.

Remove the plastic protective cap from the inlet port

prior to connection of the pump to the system. Vertical

connection of the vacuum line can be made directly to

the pump inlet (Ref. 260).

Type and size of the inlet connections of the R 5 Series

pumps are shown in the TECHNICAL DATA page 14.

If the gas that is pumped contains dust or other foreign

solid particles, a suitable inlet filter (10 micron rating or

less) should be connected to the inlet port. Consult the

factory for recommendations.

1.5 Oil Filling

The pump is shipped without oil. After level installation,

and after correct rotation has been established and with

the pump switched "off" and secured against accidental

start-up, fill the pump with the recommended vacuum

oil through the oil filling port (Ref. 88), observing the

"MAX" and "MIN" position at the oil sight glass (Ref.

83).

CAUTION: The built-in, anti-suck-back valve

is not positive action; do not use it as a sys-

tem check valve.

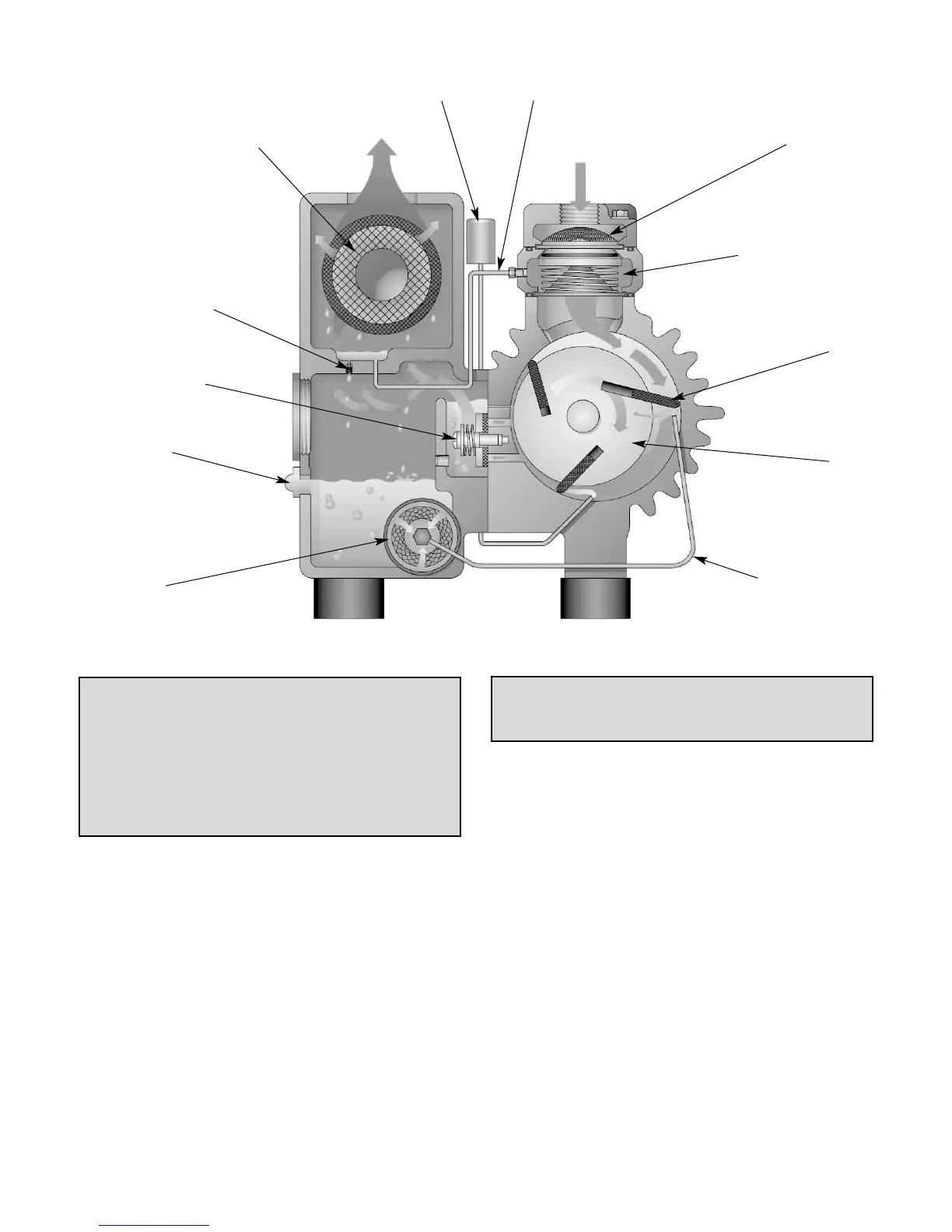

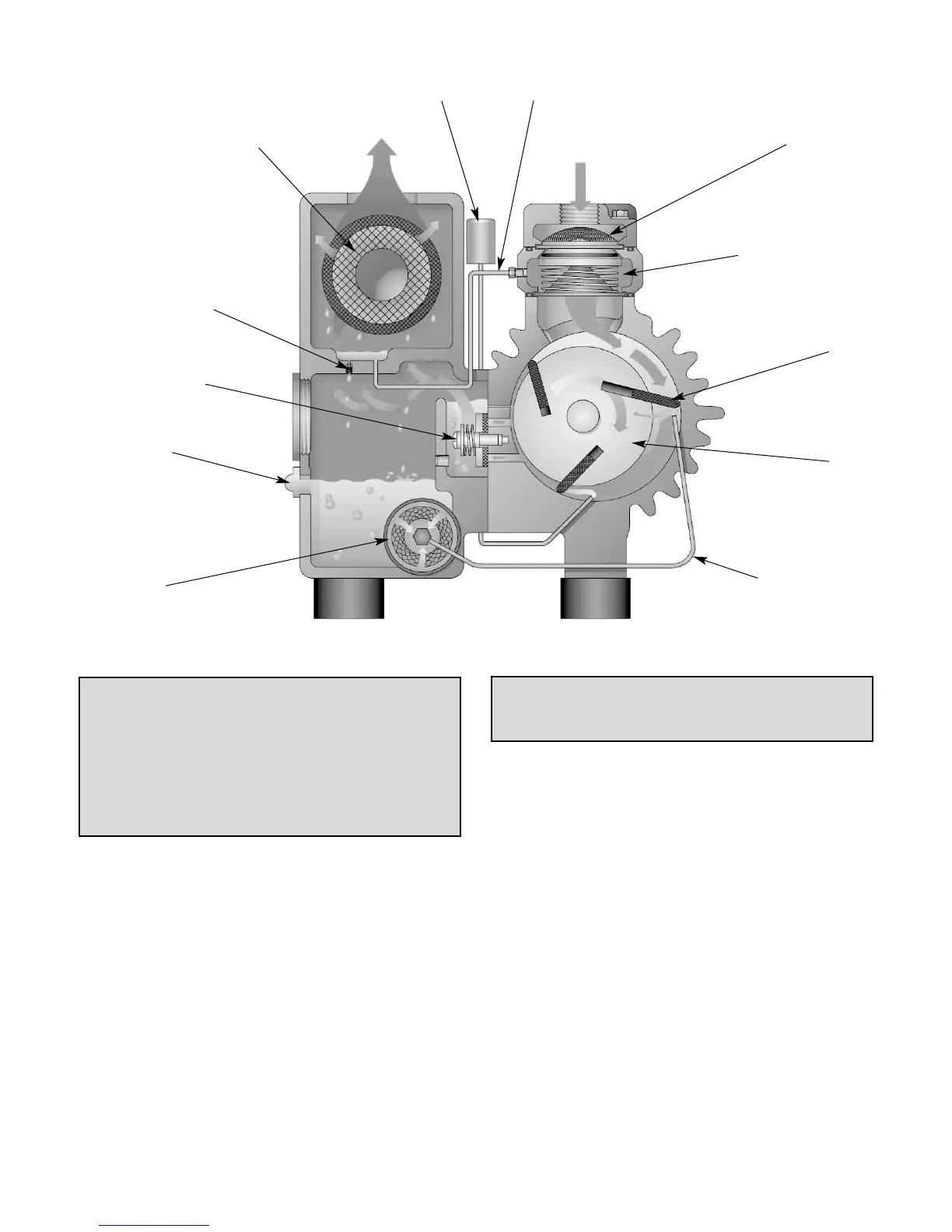

Exhaust

Inlet

Exhaust filter

Gas ballast

(RA)

Rotor

Anti-suckback valve

Inlet screen

Vane

Automotive type

spin-on filter

Main oil feed line

Exhaust valve (RA)

Oil return valve (RA)

Oil sight glass

Oil return line to

inlet (RC)

Fig. 1 - Basic R 5 Pump

CAUTION: After the electrical connection

has been made, but before the pump is

filled with oil, the rotation of the motor

must be checked. Open the inlet port and

jog the motor briefly to make sure rotation

is correct. If it runs backwards and if it is

wired three phase power, reverse any two

leads of the three at the power connection.

Loading...

Loading...