7 | Maintenance

16 / 32 0870207738_RA_RC0400-0630C_USA_-_IM_en

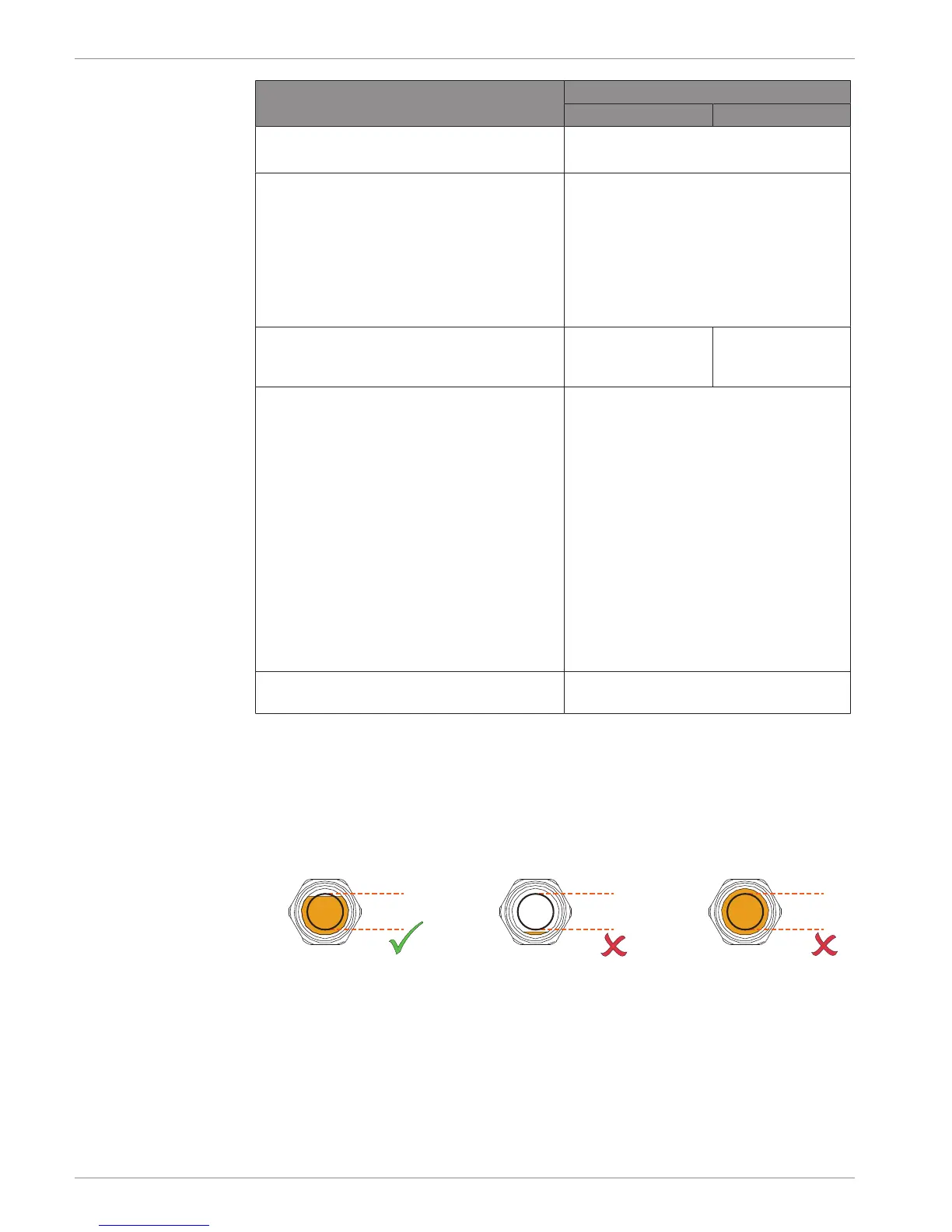

Maintenance work Interval

Normal application Harsh application

• Check the oil level, see Oil Level Inspec-

tion [►16].

Daily

• Check the vacuum pump for oil leaks - in

case of leaks have the machine repaired

(contact Busch).

• Drain drip legs on inlet and exhaust piping

In case of an inlet filter being installed:

• Check the inlet filter cartridge, replace if

necessary.

Monthly

• Change the oil*, the oil filter* (OF) and

the exhaust filters (EF).

Max. after 4000

hours, at the latest

after 1 year

Max. after 2000

hours, at the latest

after 6 months

• Clean the vacuum pump from dust and

dirt.

In case of a gas ballast valve (GB) being in-

stalled:

• Clean the gas ballast valve.

If the vacuum pump is equipped with an air-

oil heat exchanger (AHE):

• Check and/or clean the air-oil heat ex-

changer.

If the vacuum pump is equipped with a wa-

ter cooling system:

• Check and/or clean the water cooling sys-

tem.

Every 6 months

• Contact Busch for an inspection.

If required, overhaul the machine.

Every 5 years

* Service interval for synthetic oil, shorten the interval when using mineral oil, contact

Busch Service

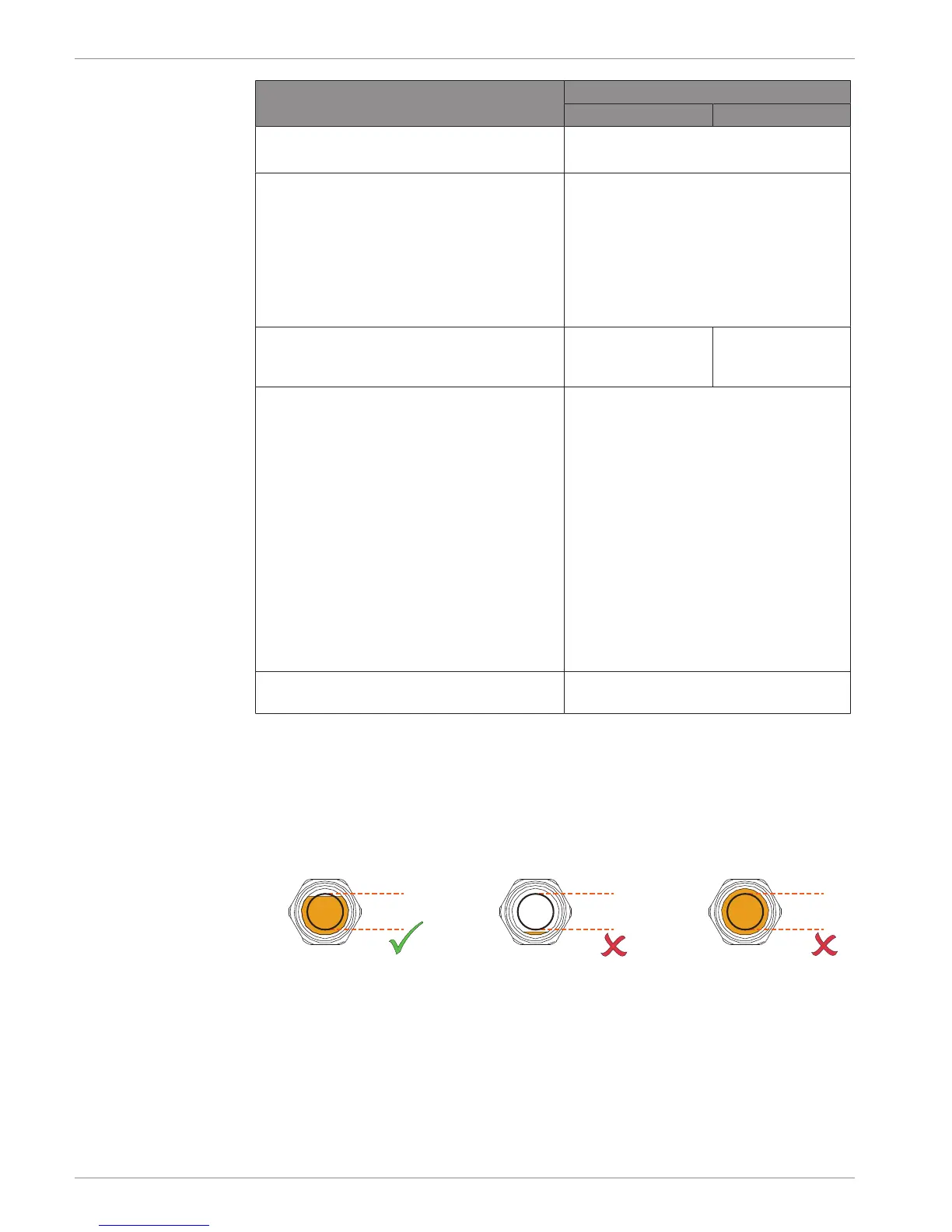

7.2 Oil Level Inspection

• Shut down the vacuum pump.

• When the vacuum pump is stopped, wait 1 minute before checking the oil level.

Loading...

Loading...