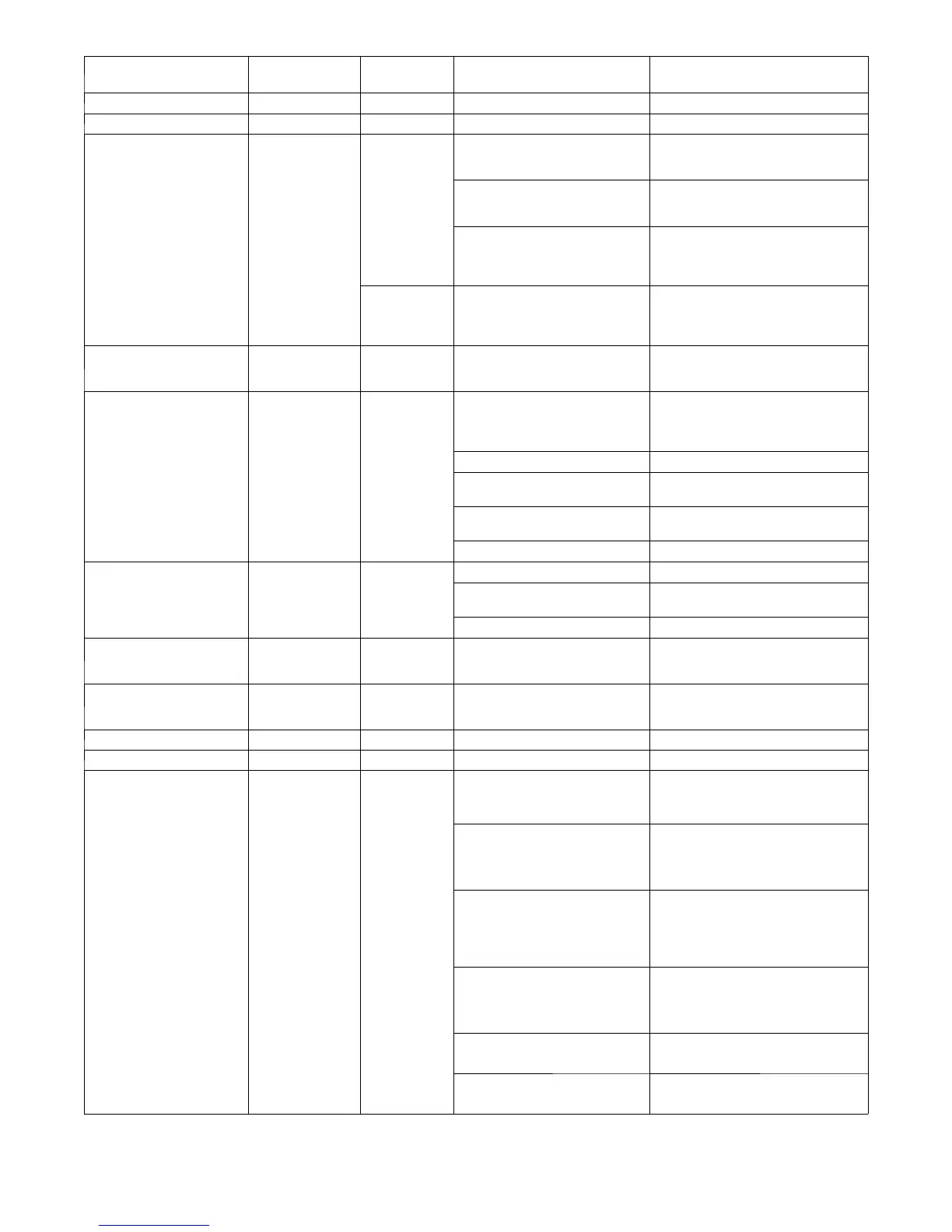

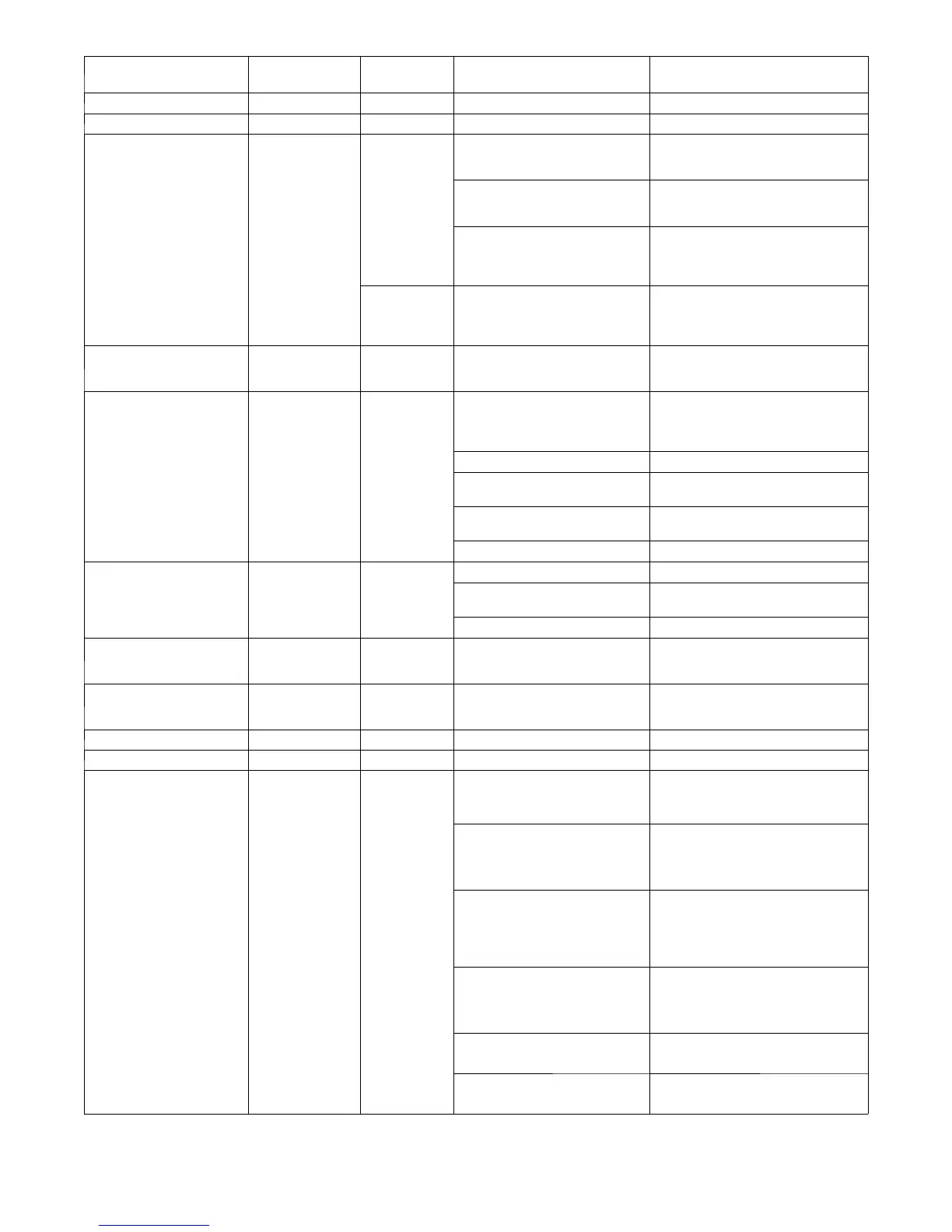

13

Table 6—25VNA EVENT / FAULT

OPERATION

FLASH CODE

(Amber LED)

Heat or Cool

Mode

Possible Causes ACTION

Standby/Charging ON, no flash --- --- --- --- --- --- --- --- ---

Variable Capacity 1, pause --- --- --- --- --- --- --- --- ---

Variable Capacity (Range

Cutback)

1(1secON),

longer pause (2

second OFF)

Both

Pressure T rip Cutback: 2 or more

High Pressure Trips occurred in

past 2 hours

System will self ---mitigate, persistent con-

ditions will lead to lockout (r ef er to E r ror

Code 84)

High Load Cu t back: 2 or more

Torque Limit Trips occurred in the

past 2 hours

System will try to self ---mitigate, persist-

ent conditions will lead to lockout (refer

to Error Code 99)

Flank Loading Cutback: Flank Load

is too high, ODU raising speed

(shrinking capacity range) to im-

prove reliability

System will try to self ---mitigate, persist-

ent conditions will lead to lockout (refer

to Error Code 99)

Heat

Oil Circulation cutback: Suction

Pressure too high for current com-

pressor speed; ODU reducing

speed to improve oil circulation

check for Indoor airflow restrictions

Emergency Mode Continuous Flash Both

Regular T ---Stat used in Emergency

mode: Nominal Capacity only (fixed

speed operation)

install Infinity User Interface

Event 16 Both

Loosewireorshortedleads

Verify communications wiring (ABCD);

check for loose connection, stripped

wires, short to ground or short between

wires

Wrong Model Plug Installed Verify correct model plug installed

Damaged Model Plug

Check model plug for corrosion or

breakage; replace if necessary

DataBuslockedupbypowerloss,

brownout or glitch

Cycle Power to system

Damaged ODU control Replace ODU control

Event 25 Both

Wrong Model Plug Installed Verify correct model plug installed

Damaged Model Plug

Check model plug for corrosion or

breakage; replace if necessary

Damaged ODU control Replace ODU control

Event 31 Both High Pressure Event

System will self ---mitigate, persistent con-

ditions will lead to lockout (r ef er to E r ror

Code 84)

Event 32 Both Low Pressure Event

System will self ---mitigate, persistent con-

ditions will lead to lockout (r ef er to E r ror

Code 83)

System Malfunction 45 Both Damaged ODU control Replace ODU control

Event 46 Both low line voltages if persistent contact power provider

System Malfunction 48 Both

Loose or disconnected harness (CC

@ HP control, CC @ contactor, IN-

VERTER @ HP control, INVERTER

@inverterdrive)

Verify good harness connection

Loosewireorshortedleads

Verify communications wiring (”Inverter”

harness); check for loose connection,

stripped wires, short to ground or short

between wires; confirm good connection

is made at control board and at Inverter

Contactor not pulled in

Verify contactor harness from ODU con-

trol (”C C” harness); check f or loose con-

nection, stripped wires, short to ground

or short between wires; confirm good

connection is made at control board and

at contactor

Damaged Contactor C oil

if wiring is ok measure across the con-

tactor coil for 18VAC --- 32VAC; if voltage

is present measure across contactor ter-

minals 21 & 23 for line voltage if absent

then contactor is damaged

Damaged ODU Control

confirm ~ 5VDC on pins 3 & 4 of ”Invert-

er” pin out connection on ODU control if

absent board is damaged

Possible damage to Inverter Drive

Change out ODU control before Inverter

Drive; if this does not help then change

out the Inverter drive

Loading...

Loading...