40MBFAQ: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

9

INTERCONNECTING PIPING

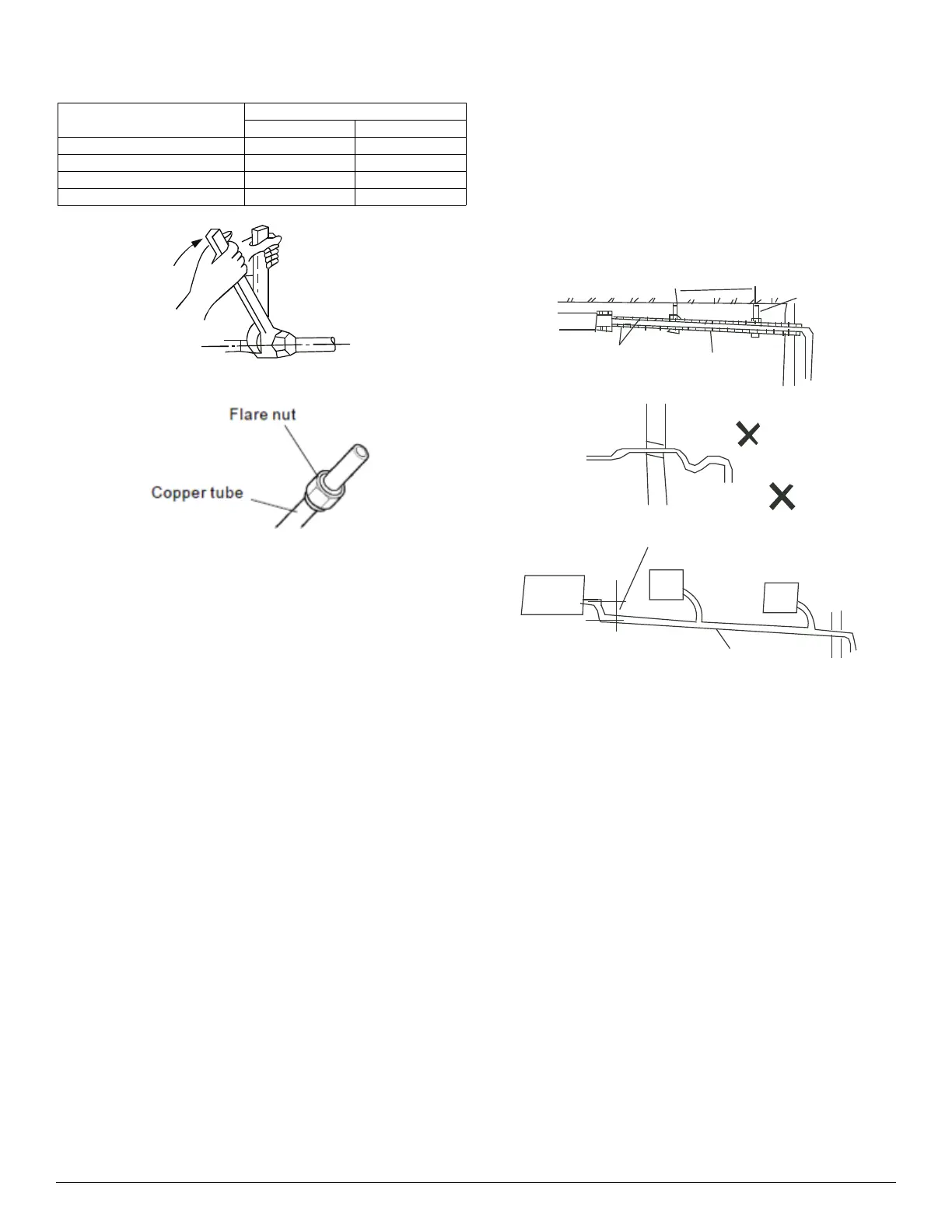

Table 7 — Tightening

Fig. 10 — Tighten

Fig. 11 — Flare Nut and Copper Tube

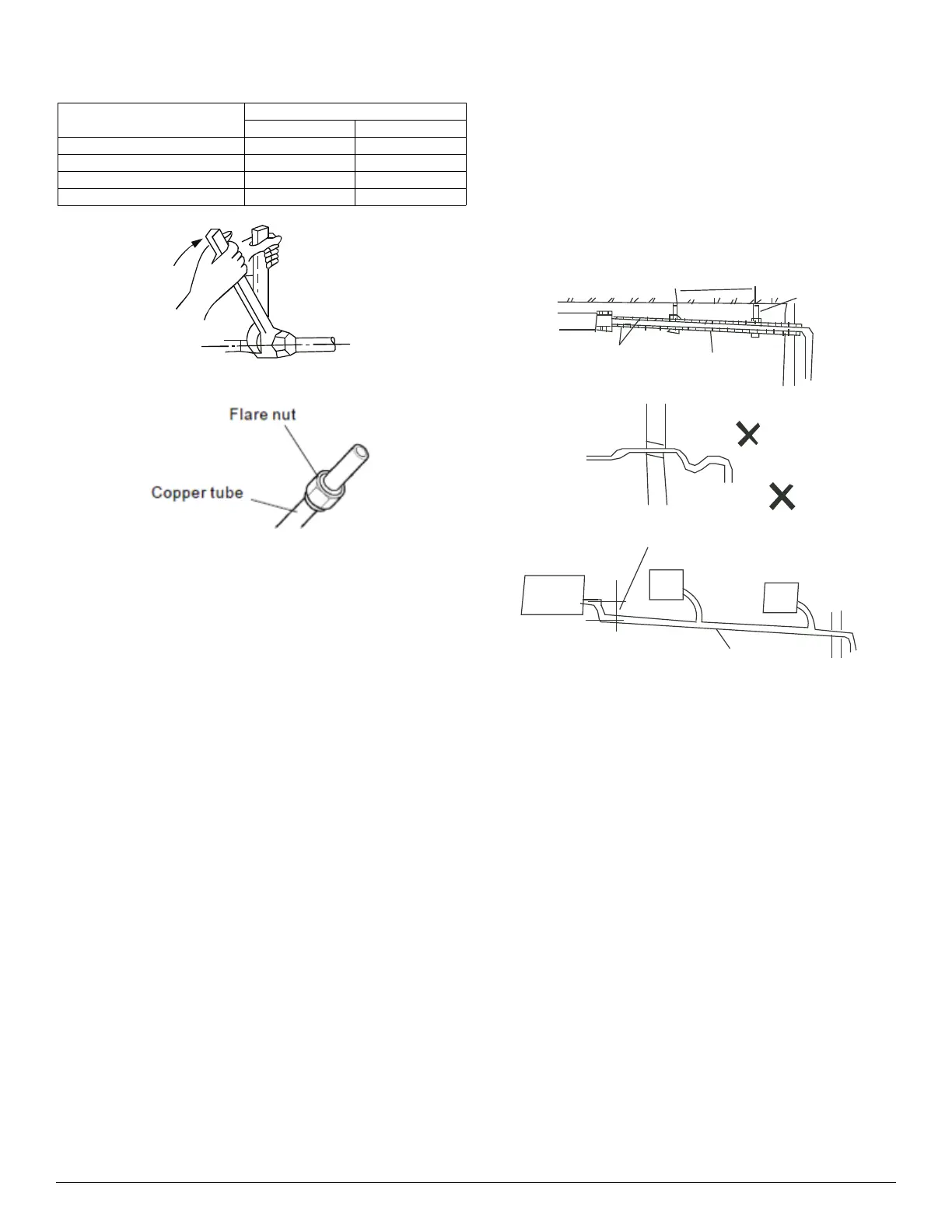

CONDENSATE DRAIN CONNECTION

The unit is supplied with a drain connection to connect the drain piping. When

installing condensate piping, follow these recommendations:

• Condensate piping should slope downward in the direction of the condensate

flow, with a minimum gradient of 1 in. per 100 inches.

• When multiple units are connected to a common condensate drain, ensure the

drain is large enough to accommodate the volume of condensate from all units.

It is also recommended to place an air vent in the condensate piping to prevent

any air locks.

• Condensate piping must not be installed where it may be exposed to freezing

temperatures.

Fig. 12 —Condensate Flow

PIPE DIAMETER INCH (MM)

TIGHTENING TORQUE

FT-LB N - M

Ø1/4” (6.35) 10 to 13 13.6 to 17.6

Ø3/8” (9.52) 24 to 31 32.5 to 42.0

Ø1/2” (12.7) 37 to 46 50.1 to 62.3

Ø5/8” (15.88) 50 to 60 67.7 to 81.3

1.5m~2m

Insulating

material

Downward declivity

lower than 1/100

Bend

S shape

VP30

lower than 1/100

Put as deep as possible

(about 10cm)

Loading...

Loading...