58SB0B/58SB1B: Installation, Start–Up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

32

connect thermostat wire to R terminal on control board and

re-install blower door.

4. Operate furnace per instruction on door.

5. Verify furnace shut down by lowering thermostat setting below

room temperature.

6. Verify furnace restarts by raising thermostat setting above room

temperature.

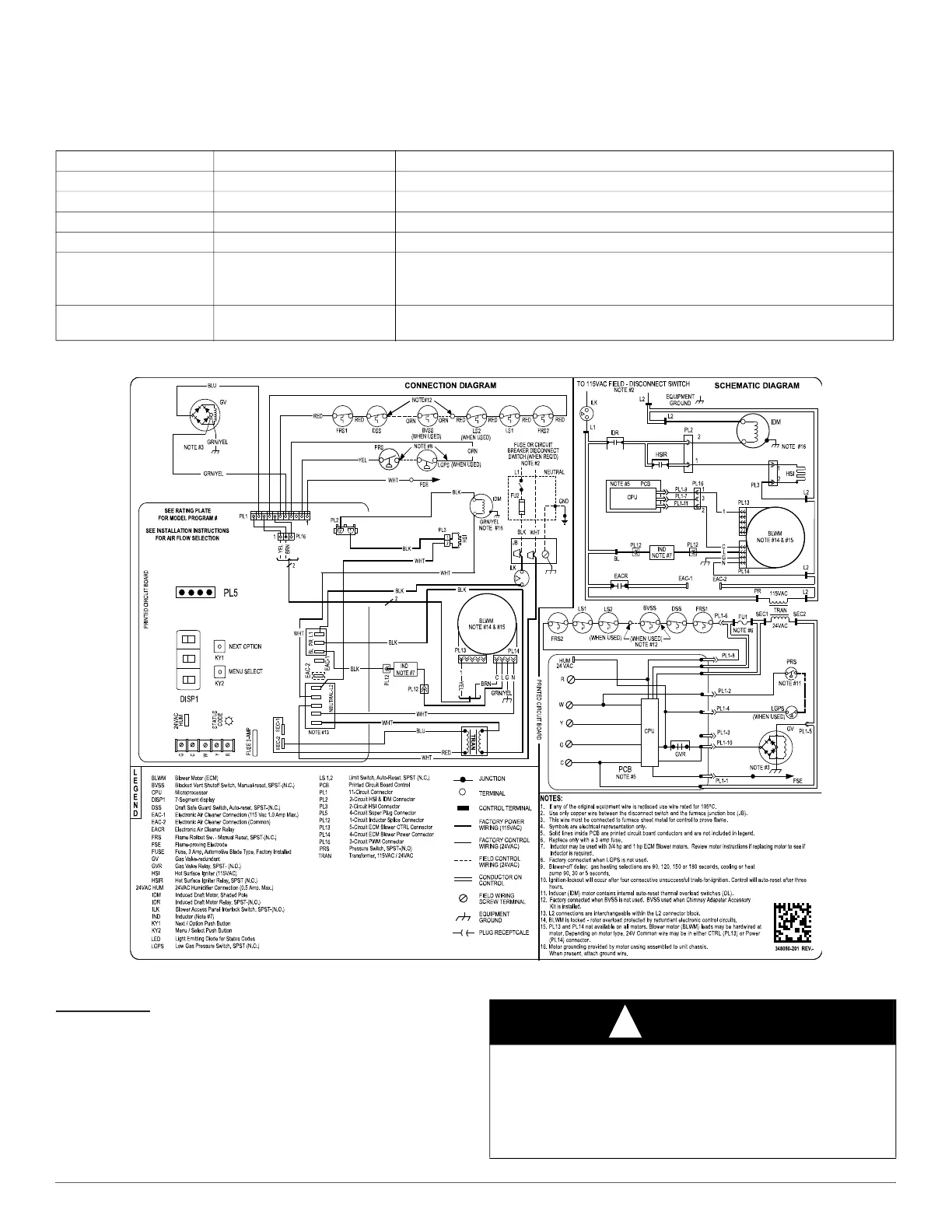

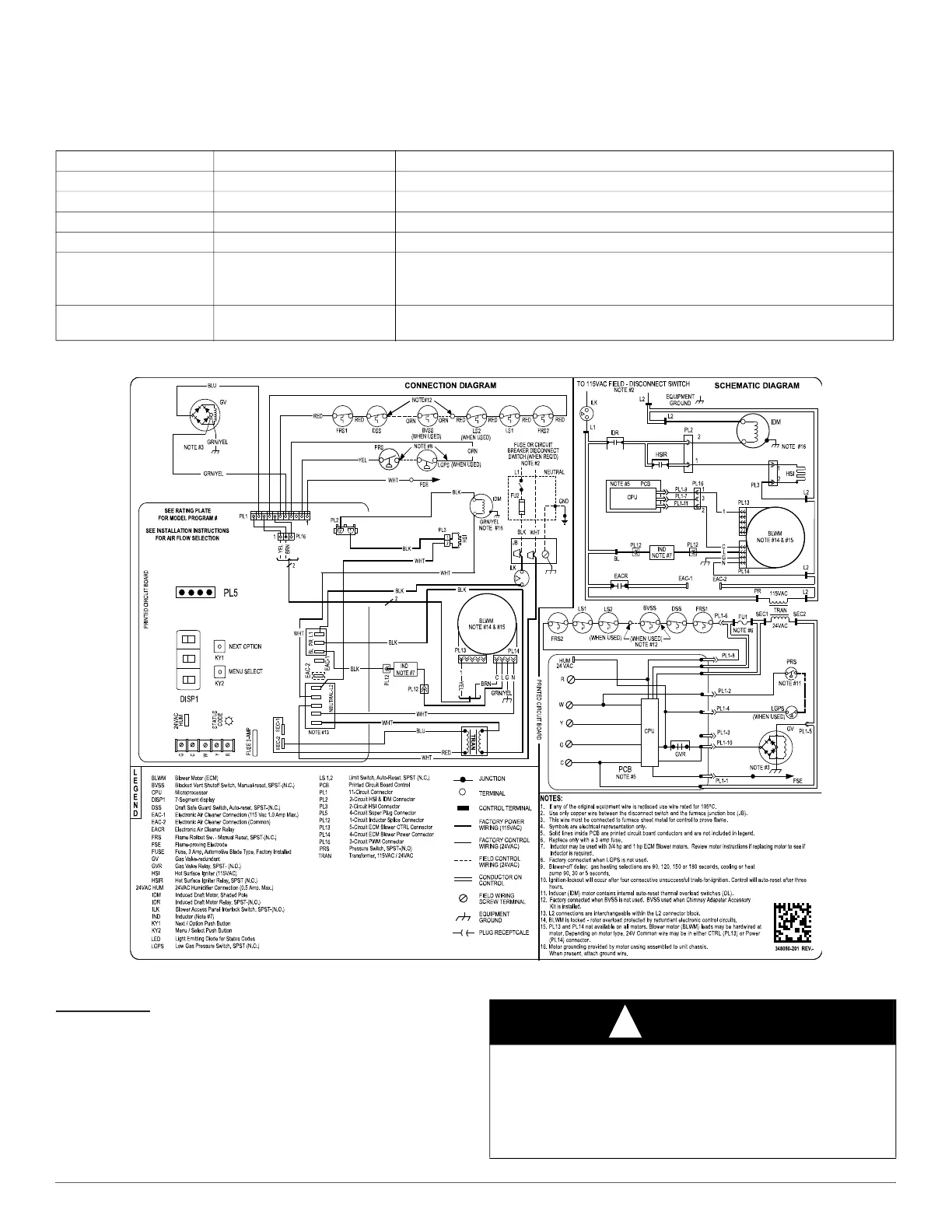

WIRING DIAGRAM

A210787

Fig. 46 – Wiring Diagram

Adjustments

Furnace gas input rate on rating plate is for installations at altitudes up to

2000 ft. (610 M). Furnace input rate must be within +/-2 percent of

furnace rating plate input.

Table 13 – Test Sequence

Display Operating Mode Function

tSt

Test

Confirms start of Component Test mode.

PUr

Purge

Inducer ON for 10 seconds before next stage. Inducer remains ON for test duration.

HSi

Hot Surface Igniter

Hot Surface Igniter ON for 15 seconds, then OFF.

Fn

Fan

Blower ON at 50% torque for 10 seconds, then OFF.

End

End Test

All component OFF except for Inducer for 10 seconds. Display returns to

iDl. If a

thermostat input is detected or fault condition activates during the test sequence, control

will abort and display

End for 6 seconds.

Err

Error

Displayed if component test is not able start. Check for thermostat inputs or faults, and

system status is Idle (

iDl).

WARNING

!

FIRE HAZARD

Failure to follow this warning could result in injury, death and/or

property damage.

DO NOT bottom out gas valve regulator adjusting screw. This can

result in unregulated manifold pressure and result in excess overfire and

heat exchanger failures.

Loading...

Loading...