58SB0B/58SB1B: Installation, Start–Up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

29

FURNACE CONTROL PROGRAMMING

AND NAVIGATION

On-Board Control Method

This furnace model is equipped with an on-board 3-digit LCD display

with pushbutton navigation for the adjustment of operating parameters,

diagnostics, and service. The control board must be powered to use the

display and pushbuttons. Upon startup, the control will alternate

displaying the Model Program Number (PRG) and Software Version

(uEr). The control board has been programmed at the factory with a

Model Program Number specific to the furnace product number. The

correct Model Program Number is shown on the furnace rating plate.

The system’s status is displayed after startup or after no control buttons

have been pressed for 60 seconds. Status Code LED will also be

illuminated or blinking when displaying the system status. The codes

which indicate the current operating mode of the system as shown in

Table 11.

The Main Menu provides access to operating parameters of the furnace

control including airflows as well as other diagnostics. See Fig. 28 for

the location of the pushbuttons. Scroll through Main Menu by pressing

MENU/SELECT button. Press NEXT/OPTION to display the current

setting of the parameter (value will flash). Additional presses will scroll

through setting options. Press MENU/SELECT button to save a new

setting and return to the Main Menu. The display will flash three times to

confirm a new setting selection has been saved. Fig. 44 shows the flow

of the menu and settings. Table 12 provides additional information on

parameter adjustment and applicability.

NFC and Supported App Method

This furnace control board is also equipped with NFC (Near Field

Communication) technology which allows the adjustment of operating

parameters, diagnostics, and service via a field-supplied mobile device

with NFC capability and supported mobile app. Remove 115-V power

from the furnace control board to use this method. See Fig. 28 for the

location of the NFC antenna. Additional instructions and help may be

available through the supported mobile app.

Scan the mobile app QR Code on page 1 of this manual for more

information and a link to download the mobile app.

Control Board Replacement

If the control board must be replaced, the new board must be

programmed with the correct Model Program Number before the furnace

will operate. Do NOT program the control board with a Model Program

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury, or death.

Blower access door switch removes 115-V power to control. No

component operation can occur unless switch is closed. Caution must

be taken when manually closing this switch for service purposes.

Do not tape or permanently allow the door switch to be bypassed.

Temporarily depress the door switch with one hand while accessing the

service buttons with your other hand. Do not touch uninsulated

electrical components.

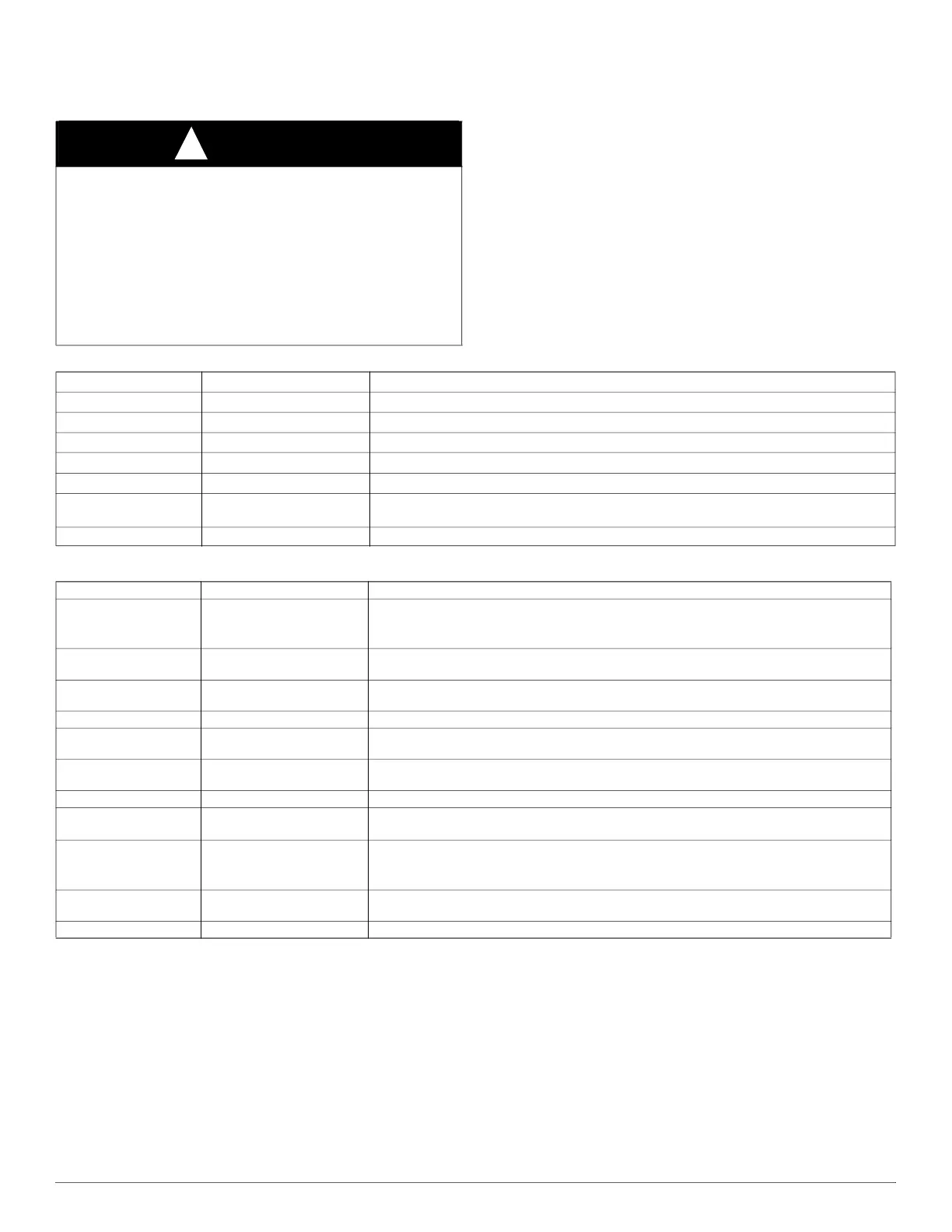

Table 11 – System Status Display Codes

Display Operating Mode Notes

iDl

Idle/Standby Mode No active demands

Ht

Heating Mode Gas Heating active

CL

Cooling Mode Cooling or Heat Pump active

Hpd

Heat Pump Defrost Mode Gas Heating cycle active during Heat Pump Defrost cycle

Cfn

Continuous Fan Mode Continuous Fan active

bLr

Secondary Unit Operating

Blower

Only used when control is the secondary furnace of a twinned furnace system and primary

furnace is active

##.# Active Status Code See Fig. 45 or Furnace Service Label for codes

Table 12 – Main Menu Options

Display Menu Item Use

FLt

Last 7 faults that occurred

Faults code menu stores the 7 latest faults in memory. If no faults, None (

non) will be

displayed. To clear fault history, scroll to Clear (

Clr) and press MENU/SELECT. See Fig. 45

or Furnace Service Label for codes.

Ht

Heating blower speed

Heating Airflow Setting. Adjust higher to lower Temp. Rise; lower to increase Temp. Rise. See

Start-Up Procedures. See Fig. 44 for allowable selections and Table 9 for airflows.

CL

Cooling and Heat Pump

blower speed

Cooling Airflow Setting. See Fig. 44 for allowable selections and Table 9 for airflows. Refer to

cooling or heat pump equipment data for required airflow settings.

Cfn

Constant Fan blower speed

Constant Fan Airflow Setting. See Fig. 44 for allowable selections and Table 9 for airflows.

HoD

Heat OFF Delay

Value shown in seconds. Shorter delays may leave unused heat in ducts. Longer delays may

blow cold air at the end of heating demands.

Cod Cool OFF Delay

Value shown in seconds. Shorter delays may leave unused energy in furnace coil. Longer

delays may re-evaporate condensate.

dir

Direction

Adjusts display orientation 180 degrees between up flow (

UPF) and down flow (dnF).

tnn

Twinning

Primary (

Pri) or Secondary (SEC) furnace selection. Adjust only if furnace is used in a

twinned furnace system. Use of accessory kit required. See kit instructions.

inF

Program # and Software

Do NOT program the control board with a Model Program Number different than what is

specified on the rating plate. Alternates displaying the saved Model Program Number (

pRG)

and Software Version (

uEr).

Ct

Component Test

Use to validate components are functioning as intended. See Component Self-Test

instructions in the Start-Up Procedures section.

rSt

Reset

Reset settings to Factory Default by selecting Yes (

YEs).

Loading...

Loading...