10

669224-R5

2.5 Prior to Operation

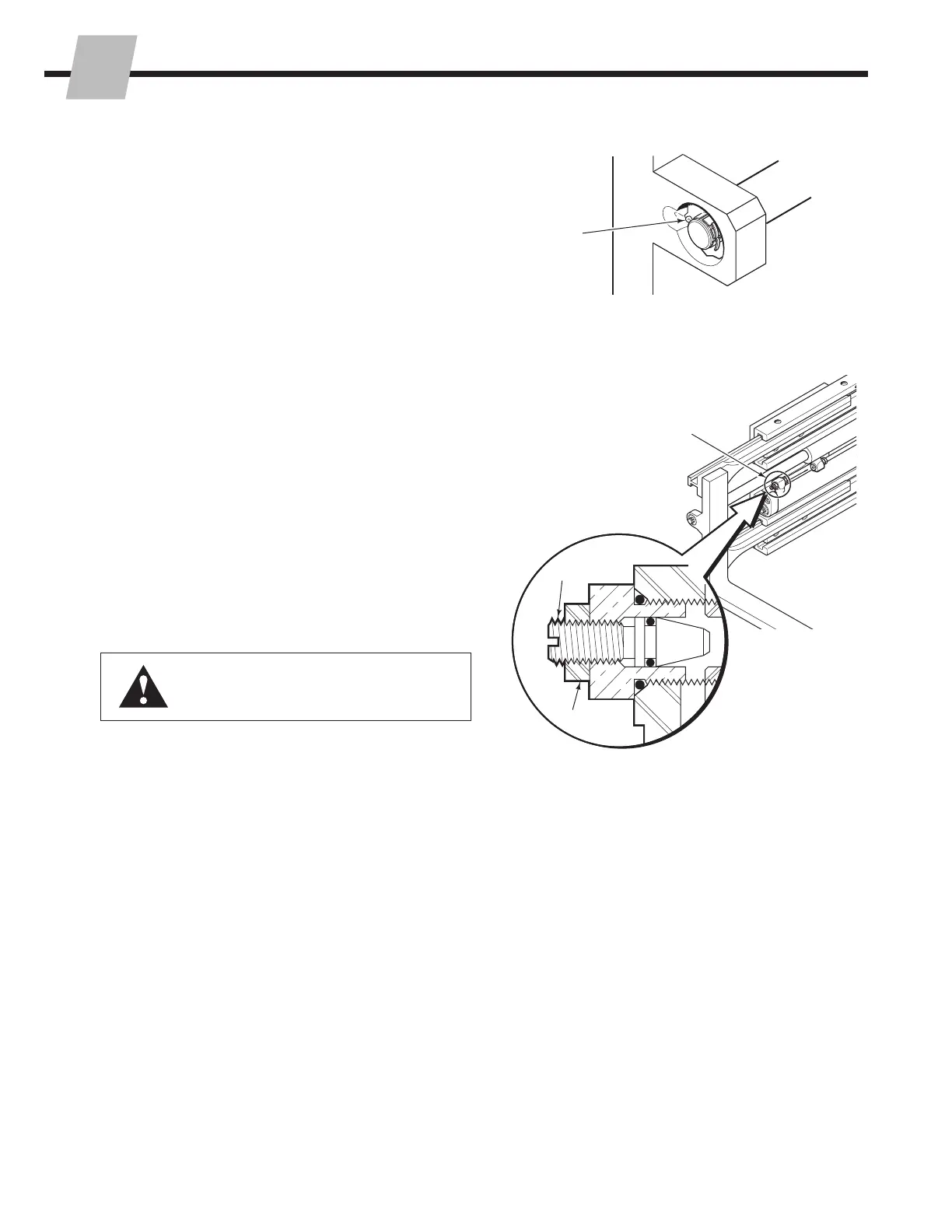

1 Check the cylinder anchor nuts for properly installed

locking caps and cotter pins.

2 Check for external leaks at the fittings and rod ends.

25D, 35D, 40D and 50D Clamps – The clamp utilizes a

regenerative hydraulic circuit in the arm opening mode.

The arms will open at a faster speed than when closing.

This is normal. If required, the regenerative function

can be eliminated. Refer to Section 5.6-5.

3 Check for equal arm travel. If arm travel is unequal, the

restrictor cartridges should be adjusted as follows:

A Loosen the jam nuts on the restrictor cartridges.

Screw in the plungers until they bottom. Screw each

plunger out three full turns.

B Activate the arms to the fully open position

C Activate the arms to close until one arm bottoms

out. Measure the amount of stroke remaining in the

opposite arm.

D If unequal closing movement exceeds 2 in. (50 mm),

screw the plunger in 1/2 turn on the cylinder that

bottoms first.

E Repeat step A through D until unequal closing

movement is less than 2 in. (50 mm).

4 Before picking up a load, cycle the clamp function

through several full cycles. Check for operation in

accordance with ITA (ISO) standards.

WARNING: Make sure all personnel are

clear of the clamp during testing.

CL0459.eps

1

3

Check for properly

installed locking

caps and cotter pins

Restrictor Cartridge

Plunger

Jam Nut

NSTALLATION

I