HELPLINE NO 08448012949

11

ORIGINAL INSTRUCTIONS

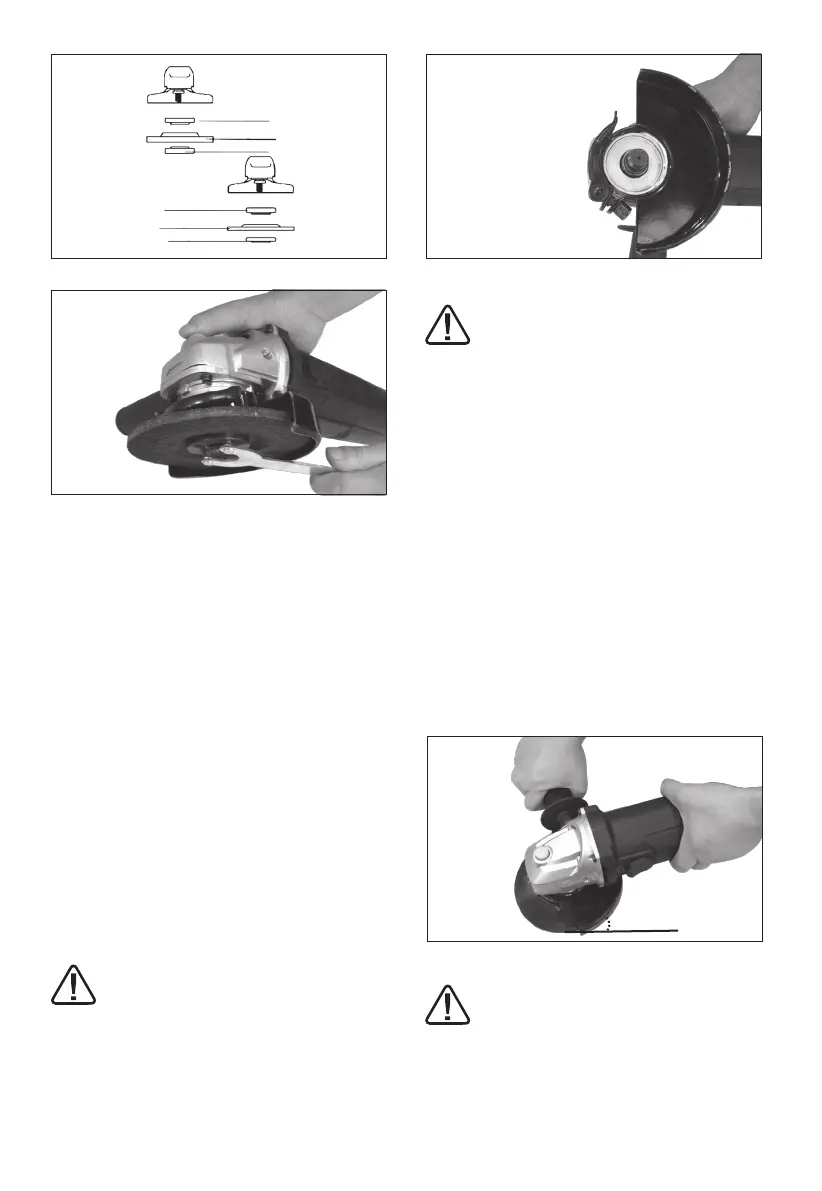

6. GUARD ADJUSTMENT (See Fig. D)

Before any work on the machine itself, pull

the mains plug.

For work with grinding or cutting discs, the

wheel guard must be mounted.

Wheel Guard for Grinding

Turn off and unplug the tool. Never operate

grinder without guard in place. Adjust the guard

to protect your hands and to direct grind debris.

Loosen the Clamping Lever. Position the guard

at the required angle. Then tighten the Clamping

Lever.

To move the guard you must release the

Clamping Lever (10). The guard can then be

rotated to provide maximum protection against

sparks and debris. Finally, tighten the Clamping

Lever until it touches the gear case.

NOTE: with the Clamping Lever open the Clamp

Adjusting Nut (9) can be adjusted to ensure the

guard is securely clamped after the Clamping

Lever is nally closed.

Wheel Guard for Cutting

WARNING! For cutting metal, always work

with the wheel guard for cutting (9).

The wheel guard for cutting (9) is mounted in the

same manner as the wheel guard for grinding (3).

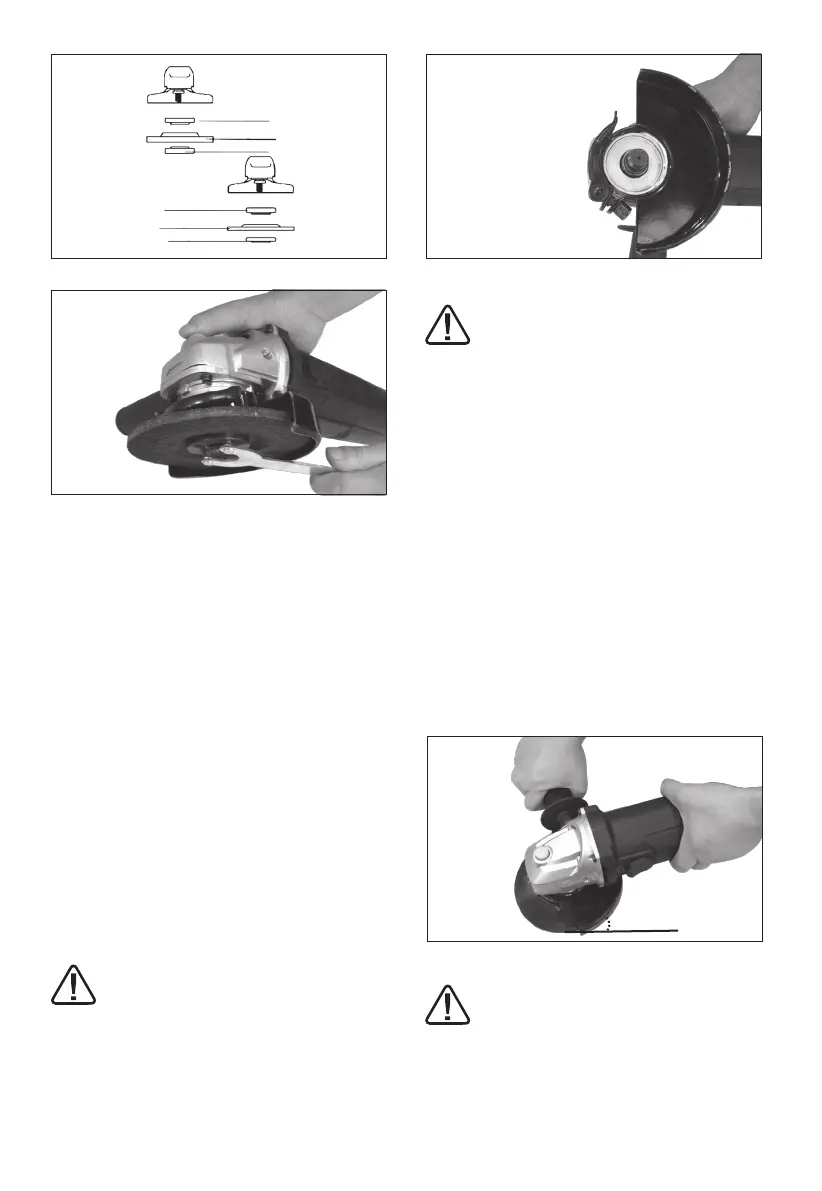

7. TO USE THE GRINDER (See Fig.E)

ATTENTION: Do not switch the grinder

on whilst the disc is in contact with the

workpiece. Allow the disc to reach full speed

before starting to grind.

Hold your angle grinder with one hand on the

main handle and other hand rmly around the

auxiliary handle.

Always position the guard so that as much of the

exposed disc as possible is pointing away from

you.

Be prepared for a stream of sparks when the disc

touches the metal.

For best tool control, material removal and

minimum overloading, maintain an angle between

the disc and work surface of approximately 15

o

-30

o

when grinding.

Use caution when working into corners as contact

with the intersecting surface may cause the

grinder to jump or twist.

When grinding is complete allow the workpiece to

cool. Do not touch the hot surface.

8. CUTTING

WARNING! For cutting metal, always work

with the wheel guard for cutting.

When cutting, do not press, tilt or oscillate the

machine. Work with moderate feed, adapted to

the material being cut.

8

4

7

8

4

7

Fig. A

Fig.B

Fig. C1

Fig. C2

Fig. C3

Fig. D

Fig. E

15

o

-30

o

8

4

7

8

4

7

Fig. A

Fig.B

Fig. C1

Fig. C2

Fig. C3

Fig. D

Fig. E

15

o

-30

o

8

4

7

8

4

7

Fig. A

Fig.B

Fig. C1

Fig. C2

Fig. C3

Fig. D

Fig. E

15

o

-30

o

Loading...

Loading...