[2] Installation

■Arrange piping so that the flow

direction agrees with the direction

of the arrow indicated on the

sensor body.

■Flash the pipe to remove foreign substances and swarf, etc., in inside of

pipe before piping.

■When piping a sensor, do not apply excessive screw-in and load torques to the

port.

When piping, apply a spanner on the metal section not to apply forces

onto the resin section.

■When piping, care must be taken that sealing tape and adhesive must

not enter into the inside.

■If a push-in joint is used, the tube must be inserted certainly. Pulls the

tube to check that the tube not be come out.

■This product can be installed with any attitude; vertical, horizontal, right

or left.

The tightening torque for screws should be 0.5N・m.

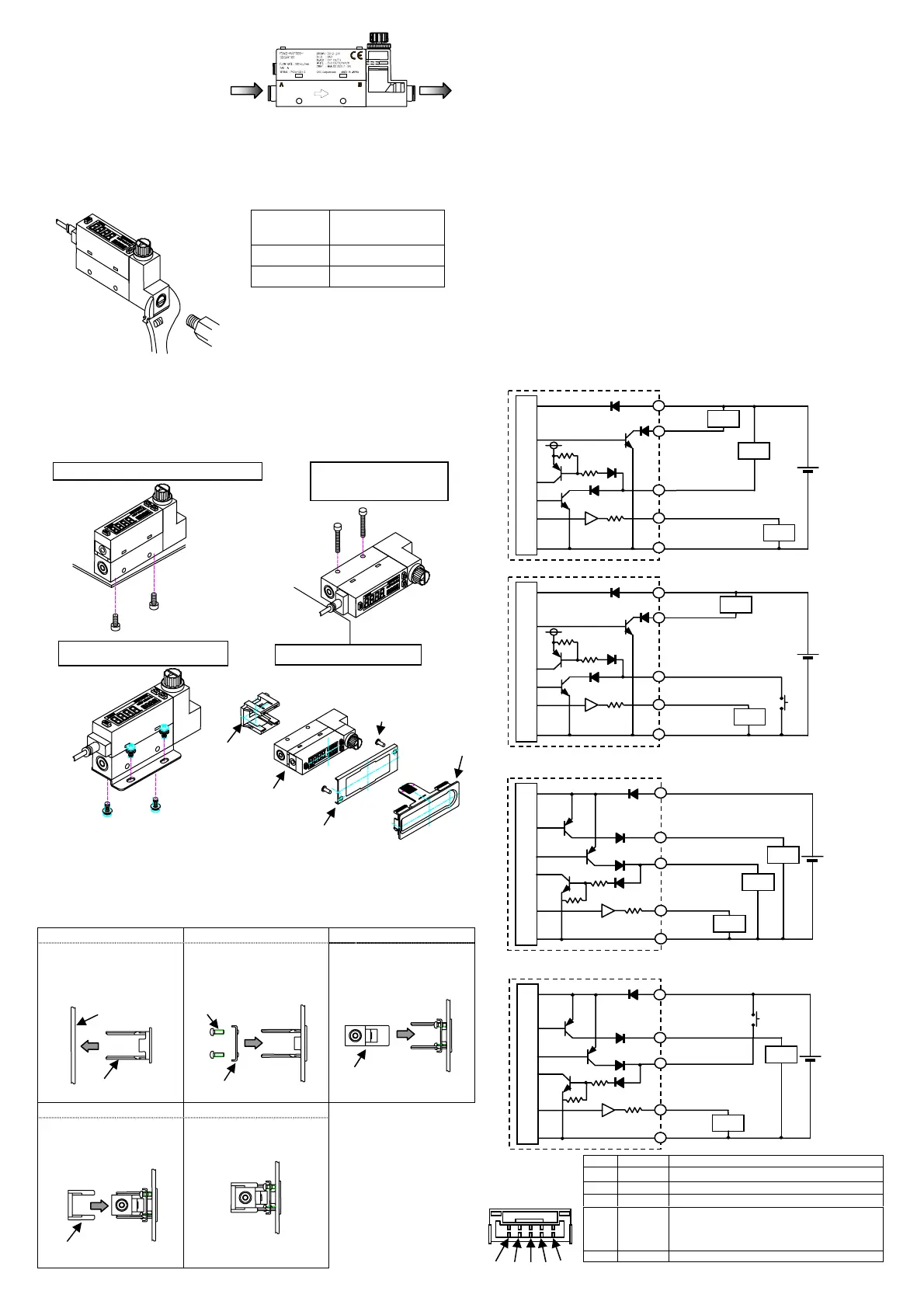

<How to panel mount>

[3] Piping

■Power supply voltage and outputs must be used with the specified

voltage. Applying the voltage more than specified voltage may cause

malfunction, damage of sensor, electric shock or fire.

Do not apply load more than the rated output. Damage or fire of the

output may be caused.

■For wiring, stop control unit/machinery and equipment, and turn off the

power supply.

■This product and wiring must be installed as far away as possible from noise

source such as strong electric line, etc. Take other countermeasures for a

surge on the power supply line.

■Do not short-circuit a load, or causing damage or burn.

■Line color must be checked when wiring. Check the wiring color with handling

precaution, since improper wire connection may result in damage, failure or

malfunction of the sensor.

■Use DC safety power supply thoroughly insulated from the AC primary side for

a power supply for the metal body (stainless steel and aluminum bodies) type,

while connecting either + or - side on the power supply to F.G.

■After the connectors are inserted, lay the connector covers over the

connectors. Make sure that stress by forcible bend of pulling is not applies

directly to the sensor cable joint.

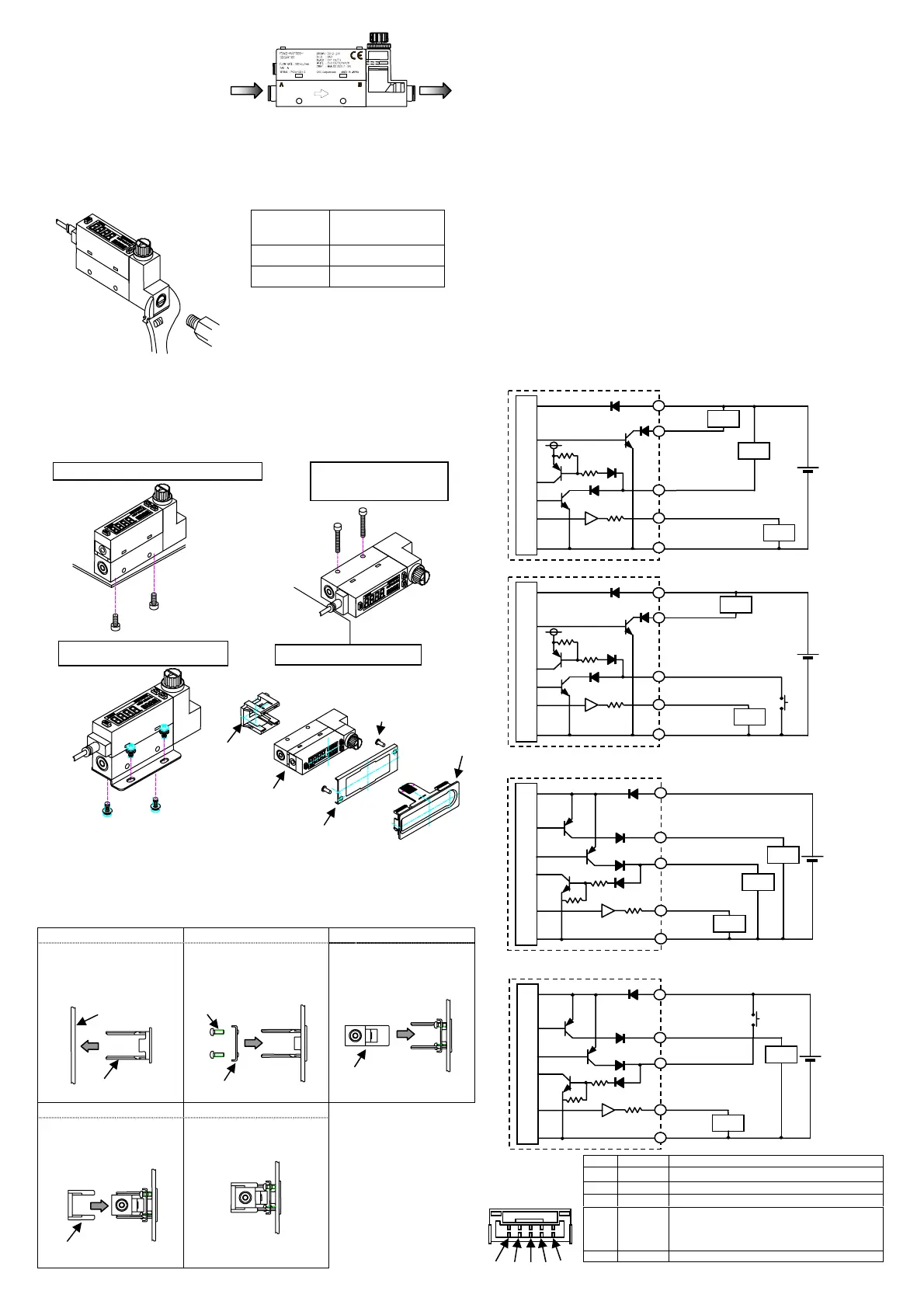

●

Example of internal circuit and load connection

NPN output

Model no.: FSM2 -N[ ]-[ ]

<CH2 function selected switch output>

<CH2 function selected external input>

PNP output Model no.: FSM2 -P[ ]-[ ]

<CH2 function selected switch output>

<CH2 function selected external input>

[1] [2] [3]

The panel bessel is inserted

from the front side of the

panel.

The panel Bessel is inserted

from the back side of the

panel, and holding with the

screw.

The separation indicator is

inserted from the back side of

the panel.

[4] [5]

The panel holder is inserted

from the back side of the

panel.

The panel holder is

pushed until the sensor is

firmly fixed, and connector is

connected.

Note:

・Please do the piping work

before it works of the panel

mount, and please do not add

the stress to parts of the

panel mount.

・ Please fix by the tightening

torque of 0.06N・m when

you fix the panel bessel

suppression.

Set screw

Tightening torque

N・m

Rc1/8

3~5

Rc1/4

6~8

Bracket (separate sales)

Model no. : FSM2-LB1

Port size: Push-in joint φ4、6、8、10

Rc1/8、Rc1/4

Main circuit

Load

Load

Load

Brown (Power supply +)

Gra

Analo

out

ut

Black (CH1)

Switch out

ut 1

White (CH2)

Switch out

ut 2

Blue

Power su

l

-

+

2

3

4

5

1

Main circuit

Load

Load

White (CH2)

External in

u

+

2

3

4

5

1

Brown (Power supply +)

Black (CH1)

Switch out

ut 1

Gray (Analog output)

Pin No. Line color Content

[1] Brown Power supply (DC 12 to 24V, DC 24V)

[2] Black CH1(Switch output 1: max50mA)

[3] White

CH2(Switch output 2: max50mA or External input)

[4] Gray

Analog voltage output : DC 1 to 5V

Connected load impedance 50kΩ and over)

Analog current output : DC 4 to 20mA

Connected load impedance 300Ω or less)

[5] Blue 0V (GND)

※Analog output voltage output type R:about1kΩ

Current output type R:about100Ω

[1]

2

[3] [4] [5]

(FSM2 side)

Vertical mount(with bottom thread)

Horizontal mount

(with through hole)

Bracket mount (with bracket)

Main circuit

Load

Load

Load

Brown (Power supply +)

Gray (Analog output)

+

Black (CH1)

Switch out

ut 1

White (CH2)

Switch output 2

2

3

4

5

1

Blue (Power supply -)

Panel mount

Panel mount kit Model no.

:FSM2-KHS-N

Panel bessel suppression

Screw

Panel

Panel bessel

Sensor

Panel holder

Main circuit

Load

Load

Brown (Power supply +)

Gray (Analog output)

+

Black (CH1)

Switch out

ut 1

White (CH2)

External input

2

3

4

5

1

Blue (Power supply -)

Panel bessel

Panel bessel suppression

Scre

Panel holder

Sensor

-2-

R※

R※

R※

Blue

Power su

l

-

R※

Loading...

Loading...