29 30

Accelerator Discharge

The discharge accelerator receives the crop from the Corn Cracker or directly from

the chopper unit and conveys it through the square discharge tube and the upper

discharge chute out of the machine at high velocity.

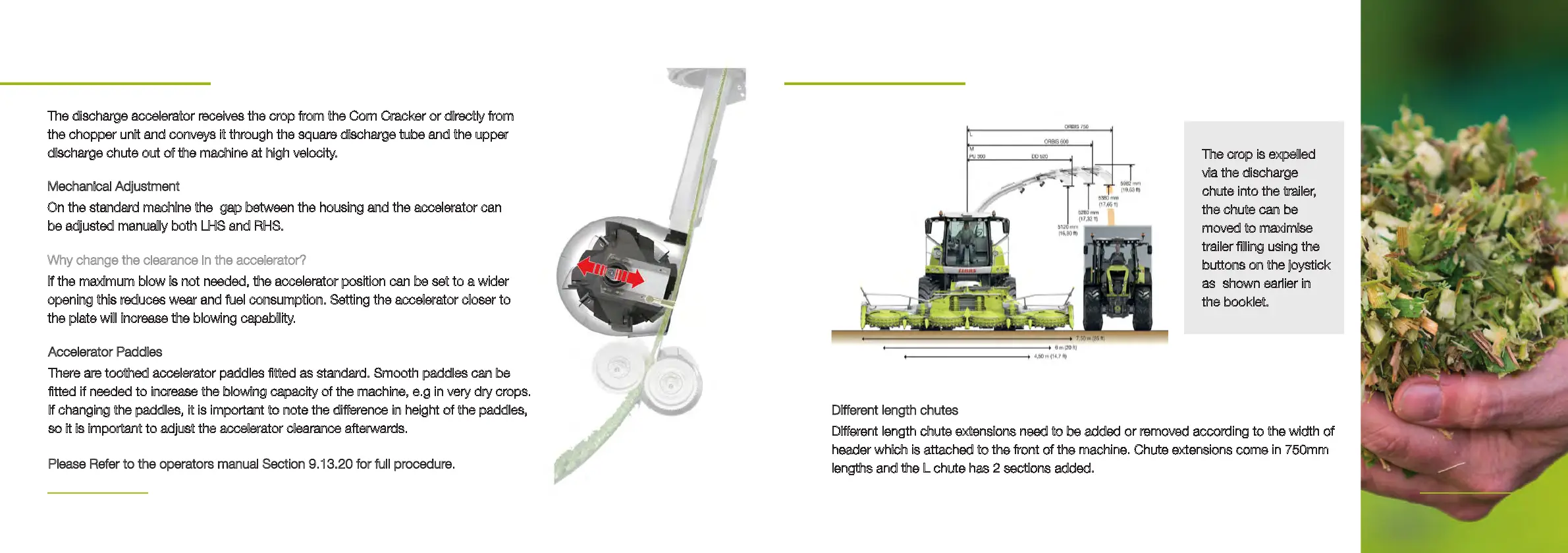

The crop is expelled

via the discharge

chute into the trailer,

the chute can be

moved to maximise

trailer lling using the

buttons on the joystick

as shown earlier in

the booklet.

Different length chutes

Different length chute extensions need to be added or removed according to the width of

header which is attached to the front of the machine. Chute extensions come in 750mm

lengths and the L chute has 2 sections added.

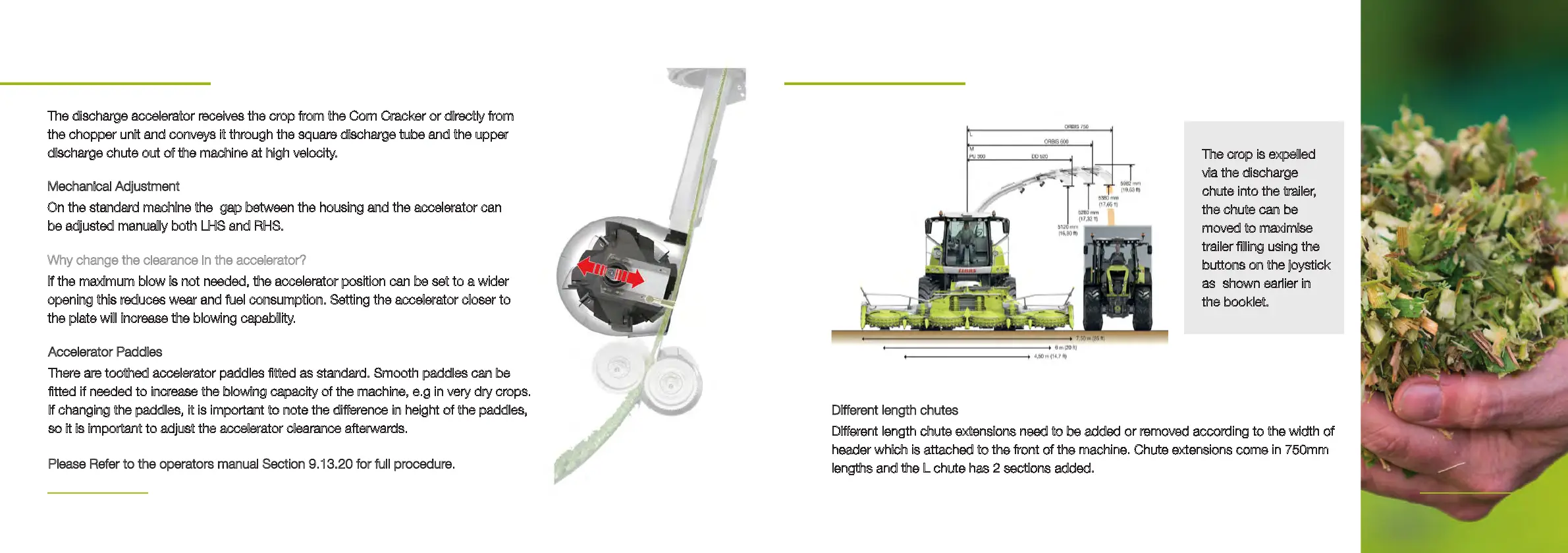

Mechanical Adjustment

On the standard machine the gap between the housing and the accelerator can

be adjusted manually both LHS and RHS.

Why change the clearance in the accelerator?

If the maximum blow is not needed, the accelerator position can be set to a wider

opening this reduces wear and fuel consumption. Setting the accelerator closer to

the plate will increase the blowing capability.

Accelerator Paddles

There are toothed accelerator paddles tted as standard. Smooth paddles can be

tted if needed to increase the blowing capacity of the machine, e.g in very dry crops.

If changing the paddles, it is important to note the difference in height of the paddles,

so it is important to adjust the accelerator clearance afterwards.

Please Refer to the operators manual Section 9.13.20 for full procedure.

Loading...

Loading...